Abstract

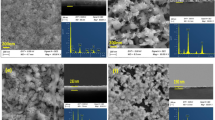

CuxSyOz thin films with various thicknesses were prepared by thermal evaporation. The structural, morphological, electrical and optical characteristics are examined for possible usage as solar control coatings on cars and architectural windows. The effect of thermal annealing on CuxSyOz films was examined for the thick film of 734 nm at 550 °C. The annealing was done for various annealing times of 2, 4 and 6 h. Energy-dispersive analysis of X-ray (EDAX) was used to evaluate the chemical composition of the as-prepared and annealed films. X-ray diffraction (XRD) elucidated the presence of hexagonal CuS and orthorhombic Cu2S together with a small contribution of the orthorhombic CuSO4 phase for the thicker films ( ≥ 241 nm). With increase in the annealing time, the hexagonal CuS and orthorhombic Cu2S peaks disappeared. The morphology of the films is strongly dependent on both thickness and annealing time. By controlling the film thickness, the transmission of the NIR region can be brought to zero, whereas adequate transmission, 6–27%, in the visible spectral region was maintained. After annealing, the transmittance increased while the reflection decreased. The optical band gap and the optical constants of the annealed films were also studied. It was found that the values can differ depending on the annealing time. The as-prepared CuxSyOz films behaves as metallic materials. It is found that room temperature resistivity decreased as the film thickness increased, while it increased with annealing.

Similar content being viewed by others

References

H. Li, L. Sun, Y. Zhao, T. Tan, Y. Zhang, Appl. Surf. Sci. 466, 309–319 (2019)

F.A. Sabah, N.M. Ahmed, Z. Hassan, H.S. Rasheed, Sensor Actuat. A Phys. 249, 68–76 (2016)

Z. Jin, Y. Li, J.C. Yu, J. Chem. Educ. 94, 476–479 (2017)

H. Hu, O. Gomez-Daza, L. Baños, Sol. Energy Mater. Sol. Cells 56, 57–65 (1998)

M. Pal, N.R. Mathews, E. Sanchez-Mora, U. Pal, F. Paraguay-Delgado, X. Mathew, J. Nanoparticle Res. 17, 1–12 (2015)

J.S. Chung, H.J. Sohn, J. Power Sourc. 108, 226–231 (2002)

N.P. Huse, A.S. Dive, K.P. Gattu, R. Sharma, Mater. Sci. Semicond. Process. 67, 62–68 (2017)

R.E. Agbenyeke, B.K. Park, T.-M. Chung, C.G. Kim, J.H. Han, Appl. Surf. Sci. 456, 501–506 (2018)

J. Liu, Z. Wu, K. Zhu, Z. Li, B. Feng, Q. Gu, P. Liu, S. Zhang, Y. You, B. Wang, J. Wang, J. Qiu, J. Alloys Compd. 685, 266–271 (2016)

R. Mandal, G. Basu, B. Ghosh, Mater. Today Proc. 5, 23099–23106 (2018)

K. Anuar, Z. Zainal, M.Z. Hussein, N. Saravanan, I. Haslina, Sol. Energy Mater. Sol. Cells 73, 351–365 (2002)

S. Deng, Y. Shen, D. Xie, Y. Lu, X. Yu, L. Yang, X. Wang, X. Xia, J. Tu, J. Energy Chem. 39, 61–67 (2019)

I. Grozdanov, M. Najdoski, J. Solid State Chem. 114, 469 (1995)

A. Bollero, M. Grossberg, B. Asenjo, M.T. Gutiérrez, Surf. Coat. Technol. 204, 593–600 (2009)

G. Lakhotiya, N. Belsare, A. Rana, V. Gupta, Curr. Appl. Phys. 19, 394–399 (2019)

G. Liu, T. Schulmeyer, J. Brotz, A. Klein, W. Jaegermann, Thin Solid Films 431–432, 477–482 (2003)

F.A. Sabah, N.M. Ahmed, Z. Hassan, H.S. Rasheed, Procedia Chem. 19, 15–20 (2016)

P. More, S. Dhanayat, K. Gattu, S. Mahajan, D. Upadhye, R. Sharma, AIP Conf. Proc. 1728, 020489 (2016)

V.S. Taur, R.A. Joshi, A.V. Ghule, R. Sharma, Renew. Energy 38, 219–223 (2012)

S. Wang, Q. Huang, X. Wen, X.-Y. Li, S. Yang, Phys. Chem. Chem. Phys. 4, 3425–3429 (2002)

T.S. De Velde, J. Dieleman, Philips Res. Rep. 28, 573 (1973)

M.A. Awad, N.M.A. Hadia, Optik 142, 334 (2017)

Y. Jiang, N. Bahlawane, J. Alloys Compd. 485, L52–L55 (2009)

Z.H. Dughaish, S.H. Mohamed, Indian J. Phys. 87, 741–746 (2013)

A. El-Denglawey, M.M. Makhlouf, M. Dongol, Results Phys. 10, 714–720 (2018)

CRC, Handbook of Chemistry and Physics, 61st, ed. by Robert C. Weast (1980-1981), p. D-70

G. Knuyt, C. Quaeyhaegens, J. D’Haen, L.M. Stals, Phys. Status Solidi B 195, 179 (1996)

S.H. Mohamed, J. Phys. D Appl. Phys. 43(035406), 8 (2010)

G. Knuyt, C. Quaeyhaegens, J. D’Haen, L.M. Stals, Thin Solid Films 258, 159 (1995)

P.B. Barna, M. Adamik, Thin Solid Films 317, 27 (1998)

V.V.V.N.S.R. Rao, K.P. Abraham, Metall. Trans. 2, 2464 (1971)

J.G. Dunn, C. Muzenda, Thermochim. Acta 369, 117–123 (2001)

R. Saxena, M.J. Frederick, G. Ramanath, W.N. Gill, J.L. Plawsky, Phys. Rev. B 72, 115425 (2005)

D.G. Gromov, S.A. Gavrilov, E.N. Redichev, S.V. Dubkov, Trends Phys. Chem. 14, 45 (2010)

B. Ren, L. Wang, J. Huang, K. Tang, Y. Yang, L. Wang, Vacuum 112, 70–72 (2015)

M.S. Alqahtani, N.M.A. Hadia, S.H. Mohamed, Optik 173, 101–109 (2018)

M.A. Rafea, A.A.M. Farag, N. Roushdy, Mater. Res. Bull. 47, 257–266 (2012)

A. Bennouna, E.L. Ameziane, Sol. Energy Mater. 22, 201–214 (1991)

D.H. Tassis, C. Dimitriadis, J. Brini, G. Kamarinos, A. Birbas, J. Appl. Phys. 85, 4091–4095 (1999)

Y.B. He, A. Polity, I. Österreicher, D. Pfisterer, R. Gregor, B.K. Meyer, M. Hardt, Phys. B Condens. Matter 308–310, 1069–1073 (2001)

C.J. Diliegros-Godines, D.I. Lombardero-Juarez, R. Machorro-Mejía, R.S. González, M. Pal, Opt. Mater. 91, 147–154 (2019)

M. Ramya, S. Ganesan, Int. J. Pure Appl. Phys. 6, 243–249 (2010)

A.C. Rastogi, S. Salkalachen, V.G. Bhide, Thin Solid Films 52, 1–10 (1978)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohamed, S.H., Hadia, N.M.A., Awad, M.A. et al. Study of the effects of both film thickness and annealing time on CuxSyOz thin films for the possibility of usage as solar control coatings. Appl. Phys. A 125, 587 (2019). https://doi.org/10.1007/s00339-019-2893-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-019-2893-1