Abstract

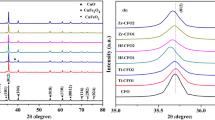

To specify the modulating mechanism of Zr substitution on the microstructure and magnetic properties of the delafossite type oxides CuFe1−xZrxO2 (x = 0–0.10), the multiferroic ceramics are synthesized by the solid-state reaction method. The microstructure and properties of the obtained samples are characterized by X-ray diffraction, scanning electron microscope, Raman spectroscopy, positron annihilation lifetime spectra and physical property measurement system. The XRD results indicate that all samples form delafossite structure, and Zr4+ substitution induces the shift of the main diffraction peaks. SEM measurements demonstrate that Zr substitution suppresses the grain growth. Raman spectra results show that Zr substitution changes the degree of polarization and intragranular stress for the CuFe1−xZrxO2 samples. Positron annihilation results suggest that vacancy-type defects exist in all samples, and the concentration and size of defects are influenced significantly by Zr substitution. The M–T curves of all samples display two successive magnetic transition temperatures TN1 and TN2, and the substitution of Zr for Fe tends to suppress the low ferromagnetic interactions in the magnetic structure. Simultaneously, all samples exhibit macroscopic weak ferromagnetic behavior at low temperature.

Similar content being viewed by others

References

T. Elkhouni, M. Amami, C.V. Colin, A.B. Salah, Mater. Res. Bull. 53, 15 (2014)

K. Mori, M. Hachisu, T. Yamazaki, Y. Ichiyanagi, J. Appl. Phys. 117, 17C756 (2015)

L.R. Shi, Z. Jin, B.R. Chen, N.M. Xia, H.K. Zuo, Y.S. Wang, Z.W. Ouyang, Z.C. Xia, J. Magn. Magn. Mater. 372, 7 (2014)

S. Seki, Y. Yamasaki, Y. Shiomi, S. Iguchi, Y. Onose, Y. Tokura, Phys. Rev. B 75, 100403 (2007)

Y. Narumi, T. Nakamura, H. Ikeno, N. Terada, T. Morioka, K. Saito, H. Kitazawa, K. Kindo, H. Nojiri, J. Phys. Soc. Jpn. 85, 114705 (2016)

T. Elkhoun, M. Amami, E.K. Hlil, A.B. Salah, J. Supercond. Nov. Magn. 28, 1439 (2015)

B. Kundys, A. Maignan, D. Pelloquin, C. Simon, Solid. State. Sc. 11, 1035 (2009)

N.Terada, T.Nakajima, S.Mitsuda, H., K. Kitazawa, N. Kaneko, Metoki, Phys. Rev. B 78, 014101–014101 (2008)

K. Hayashi, R. Fukatsu, T. Nozaki, Y. Miyazaki, T. Kajitani, Phys. Rev. B 87, 064418 (2013)

Y. Hongaromkij, C. Rudradawong, C. Ruttanapun, J. Mater. Sci. Mater. Electron. 27, 6438 (2016)

G.F. Cheng, W. Liu, Z.W. Liu, X.S. Wu, J. Magn. Magn. Mater. 382, 179 (2015)

O. Cojocaru-Miredin, P.-P. Choi, D. Abou-Ras, S.S. Schmidt, R. Caballero, D. Raabe, IEEE J. Photovolt. 1, 207 (2011)

N. Terada, D.D. Khalyavin, P. Manuel, T. Osakabe, P.G. Radaelli, H. Kitazawa, Phys. Rev. B 89, 220403 (2014)

N.P. Salke, K. Kamali, T.R. Ravindran, G. Balakrishnan, R. Rao, Vib. Spectrosc. 81, 112 (2015)

P. Shojan, A. Pavunny, R.S. Kumar, Katiyar, J. Appl. Phys. 107, 013522 (2010)

T. Elkhoun, M. Amami, E.K. Hlil, A. Ben Salah, J. Supercond. Nov. Magn. 28, 1439 (2015)

Y.H. Chuai, B. Hu, Y.D. Li, H.Z. Shen, C.T. Zheng, Y.D. Wang, J. Alloy. Compd. 627, 299 (2015)

T. Li, J. Chen, D.W. Liu, Z.X. Z hang, Z.P. Chen, Z. Li, X.Z. Cao, B.Y. Wang, Ceram. Int. 40, 9061 (2014)

T. Li, Y.C. Xue, Z. Chen, F.G. Chang, Mater. Sci. Eng. B. 158, 58 (2009)

S. Fu, Y. Zhang, H. Liu, D. Yi, B. Wang, Y. Jiang, Z. Chen, N. Qi, J. Mater. Sci. Technol. 34, 335 (2018)

R.Z. Xue, Z.P. Chen, Y.C. Xue, H.Y. Dai, T. Li, J. Chen, J. Supercond. Nov. Magn. 27, 1201 (2013)

W.N. Ge, X.N. Li, J.P. Xu, S.J. Huang, J.D. Liu, Z. Zhu, Z.P. Fu, Y.L. Lu, B.J. Ye, Nucl. Instrum. Methods B. 394, 61 (2017)

H.F. He, X.F. Li, Z.Q. Chen, Y. Zheng, D.W. Yang, X.F. Tang, J. Phys. Chem. C 118, 2389 (2014)

Y.W. Zhou, W.W. Xu, J.J. Li, C.S. Yin, Y. Liu, B. Zhao, Z.Q. Chen, C.Q. He, W.F. Mao, K. Ito, J. Appl. Phys. 123, 025706 (2018)

H.Y. Dai, L.T. Gu, X.Y. Xie, T. Li, Z.P. Chen, Z.J. Li, J. Mater Sci. Mater. Electron. 29, 2275 (2017)

R.Z. Xue, G.Y. Zhao, J. Chen, Z.P. Chen, D.W. Liu, Mater. Res. Bull. 76, 124 (2016)

H. Dai, F.J. Ye, Z.P. Chen, T. Li, D.W. Liu, J. Alloy. Compd. 734, 60 (2018)

S. Pattanayak, R.N.P. Choudhary, P.R. Das, S.R. Shannigrahi, Ceram. Int. 40, 7983 (2014)

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Project nos. 11675149, 11775192).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dai, H., Ye, F., Li, T. et al. Effect of Zr substitution on the microstructure and magnetic properties of CuFeO2 ceramics. Appl. Phys. A 125, 43 (2019). https://doi.org/10.1007/s00339-018-2354-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-2354-2