Abstract

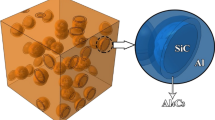

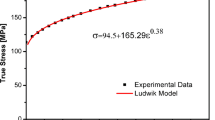

Molecular dynamics (MD) models for the study on the mechanical properties of β-SiC particles-reinforced aluminum matrix nano-composites (Al/SiC nano-composites) are established. The nano-composites in the model are fabricated by a powder metallurgy (P/M) process, followed by a hot isostatic pressing and then annealing to room temperature. The fabricated nano-composites have dense and even distributions of reinforced particles. Then representative volume elements (RVEs) of the fabricated nano-composites are built by adding periodic boundary conditions (PBCs). In this way, RVEs with different volume fractions and particle sizes of SiC are produced and put into the simulation of tension tests. The elasticity and strength in single axial tension obtained from MD analysis are in good agreement with those calculated according to the rule of mixture. It is found that the dispersion of SiC particles into the Al matrix leads to a significant enhancement in the strength of nano-composites compared to pure Al, which is also dramatically affected by both the volume fraction and particle size. Additionally, the Al/SiC nano-composites with finer SiC particles get greater enhancement in the mechanical behavior than those with coarser ones. MD analysis clearly shows the contributions of load-transfer effect, thermal mismatch strengthening and Orowan strengthening to the strengthening of Al/SiC nano-composites.

Similar content being viewed by others

References

J.J. Bhattacharyya, R. Mitra, Mater. Sci. Eng. A 557(1), 92–105 (2012)

H. Su, W. Gao, Z. Feng, Z. Lu, Mater. Des. 36(Complete), 590–596 (2012)

Y. Yang, J. Lan, X. Li, Mater. Sci. Eng. A 380(1–2), 378–383 (2004)

K.M. Mussert, W.P. Vellinga, A. Bakker, J. Mater. Sci. 37(4), 789–794 (2002)

M. Kök, Composites Part A 37(3), 457–464 (2006)

T. Varol, A. Canakci, Powder Technol. 246(9), 462–472 (2013)

B. Cheng, A.H.W. Ngan, Comput. Mater. Sci. 74(74), 1–11 (2013)

T. Varol, A. Canakci, S. Ozsahin, Composites Part B 54(8), 224–233 (2013)

M. Moazami-Goudarzi, F. Akhlaghi, Mater. Technol. 27(2), 158–164 (2014)

Z.G. Wang, C.P. Li, H.Y. Wang, X. Zhu, M. Wu 1, Q.C. Jiang, Powder Metal. 59(4), 236–241 (2016)

G. Jiang, G.S. Daehn, R.H. Wagoner, Powder Metall. 46(1), 78–82 (2013)

M. Moazami-Goudarzi, F. Akhlaghi, Part. Sci. Technol. 31(3), 234–240 (2013)

B.K. Choi, G.H. Yoon, S. Lee, Composites Part B. 91, 119–125 (2016)

J.F. Xiang, L.J. Xie, S.A. Meguid, S.Q. Pang, J. Yi, Y. Zhang, R. Liang, Comput. Mater. Sci. 128, 359–372 (2017)

V. Tomar, V. Samvedi, H.S. Kim, Int. J. Multiscale Comput. Eng. 8(8), 87–88 (2013)

M. Tavakol, M. Mahnama, R. Naghdabadi, Comput. Mater. Sci. 125, 255–262 (2016)

D. Zhang, L. Nastac, JOM 68(12), 1–9 (2016)

H. Gu, X.L. Gao, X.C. Li, J. Comput. Theor. Nanostruct 6(1), 61–72 (2009)

J.M. Winey, A. Kubota, Y.M. Gupta, Model. Simul. Mater. Sci. Eng. 17(5), 055004 (2010)

Z. Yang, Z. Lu, Composites Part B. 44(1), 453–457 (2013)

C.R. Dandekar, Y.C. Shin, Composites Part A. 42(4), 355–363 (2011)

A.P. Thompson, S.J. Plimpton, W. Mattson, J. Chem. Phys. 131(15), 154107 (2009)

A.K. Subramaniyan, C.T. Sun, Int. J. Solids Struct. 45(14), 4340–4346 (2008)

S. Plimpton, J. Comput. Phys. 117(1), 1–19 (1995)

P. Vashishta, R.K. Kalia, A. Nakano, J. Appl. Phys. 101(10), 217–340 (2007)

J.M. Winey, A. Kubota, Y.M. Gupta, Modell. Simul. Mater. Sci. Eng. 17, 055004 (2009)

W.X. Wang, L.S. Niu, Y.Y. Zhang, E.Q. Lin, Comput. Mater. Sci. 62, 195–202 (2012)

Y. Mishin, D. Farkas, M.J. Mehl, D.A. Papaconstantopoulos, Phys. Rev. B 59, 3393–3407 (1999)

W.R. Lambrecht, B. Segall, M. Methfessel, S.M. Van, Phys. Rev. B: Condens. Mater. 44(8), 3685–3694 (1991)

Y.L. Liu, D.K. Shao, Y.T. Zeng, T. Yun, Adv. Intell. Syst. Res. 136, 139–146 (2016)

A. Stukowski, Modell. Simul. Mater. Sci. Eng. 20(4), 45021–45035 (2012). 15)

Z. Yang, Z. Lu, Y.P. Zhao, Comput. Mater. Sci. 46(1), 142–150 (2009)

M.R. Sorensen, M. Brandbyge, K.W. Jacobsen, Phys. Rev. B. 57(6), 3283 (1998)

N. Silvestre, B. Faria, J.N.C. Canongia Lopes, Compos. Sci. Technol. 90(2), 16–24 (2014)

C.S. Goh, J. Wei, L.C. Lee, M. Gupta, Acta Mater. 55(15), 5115–5121 (2007)

A. Stukowski, V.V. Bulatov, A. Arsenlis, Modell. Simul. Mater. Sci. Eng. 20(8), 085007 (2012)

J.E. Bailey, P.B. Hirsch, Philos. Mag. 5(53), 485–497 (2012)

S. Queyreau, G. Monnet, B. Devincre, Acta Mater. 58(17), 5586–5595 (2010)

K. Ma, H. Wen, T. Hu, T.D. Topping, D. Isheim, Acta Mater. 62(5), 141–155 (2014)

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Item No. 51575051). The authors are grateful to the Deanship of Scientific Research, King Saud University for funding through Vice Deanship of Scientific Research Chairs.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huo, S., Xie, L., Xiang, J. et al. Atomic-level study on mechanical properties and strengthening mechanisms of Al/SiC nano-composites. Appl. Phys. A 124, 209 (2018). https://doi.org/10.1007/s00339-018-1624-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-1624-3