Abstract

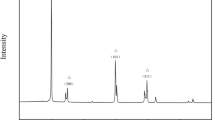

In this paper, Cu52Zr37Ti8In3 bulk metallic glass has been studied by nanoindentation. Three different ways for nanoindentation tests were employed. Load-control nanoindentation was used to investigate the effect of the loading rate on the hardness and Young’s modulus. Young’s modulus of the specimen shows a loading rate dependence. The constant-load indentation creep measurement was performed. The creep data were fitted with the generalized Kelvin model, and the compliance spectrum and retardation spectrum were derived. Furthermore, the storage compliance and loss compliance were also discussed. For characterizing the change of the hardness and Young’s modulus with increasing indentation depth, depth-control nanoindentation analysis was conducted. The results show that both the hardness and Young’s modulus decrease with nanoindentation depth.

Similar content being viewed by others

References

D.C. Hofmann, J.Y. Suh, A. Wiest, G. Duan, M.L. Lind, M.D. Demetriou, W.L. Johnson, Nature 451, 1085 (2008)

W.H. Wang, Prog. Mater. Sci. 52, 540 (2007)

J.H. Xia, J.B. Qiang, Y.M. Wang, Q. Wang, C. Dong, Appl. Phys. Lett. 88, 101907 (2006)

E.S. Park, H.J. Chang, D.H. Kim, Acta Mater. 56, 3120 (2008)

J. Wu, Y. Pan, J. Huang, J. Pi, Thermochim. Acta 552, 15 (2013)

T. Burgess, K.J. Laws, M. Ferry, Acta Mater. 56, 4829 (2008)

Y.H. Lee, J.Y. Kim, S.H. Nahm, D. Kwon, Mater. Sci. Eng. A 449, 185 (2007)

L.A. Deibler, J.J. Lewandowski, Mater. Sci. Eng. A 527, 2214 (2010)

B.C. Wei, L.C. Zhang, T.H. Zhang, D.M. Xing, J. Das, J. Eckert, J. Mater. Res. 22, 258 (2007)

D. Fatay, J. Gubicza, J. Lendvai, J. Alloys Compd. 434, 75 (2007)

Y.D. Sun, Z.Q. Li, J.S. Liu, M.Q. Cong, J.Y. Qin, J. Rare Earths 29, 253 (2011)

W.H. Li, K. Shin, C.G. Lee, B.C. Wei, T.H. Zhang, Y.Z. He, Mater. Sci. Eng. A 478, 371 (2008)

B.C. Wei, T.H. Zhang, W.H. Li, D.M. Xing, L.C. Zhang, Y.R. Wang, Mater. Trans. 46, 2959 (2005)

W.C. Oliver, G.M. Pharr, J. Mater. Res. 7, 1564 (1992)

W.C. Oliver, G.M. Pharr, J. Mater. Res. 19, 3 (2004)

Y.F. Xue, H.N. Cai, L. Wang, F.C. Wang, H.F. Zhang, Mater. Sci. Eng. A 473, 105 (2008)

M.H. Cohen, D. Turnbull, J. Chem. Phys. 31, 1164 (1959)

D. Turnbull, M.H. Cohen, J. Chem. Phys. 34, 120 (1961)

J. Sort, J. Fornell, W. Li, S. Surinach, M.D. Baro, J. Mater. Res. 24, 918 (2009)

J.J. Pang, M.J. Tan, K.M. Liew, C. Shearwood, Physica B 407, 340 (2012)

J.C.M. Li, Mater. Sci. Eng. A 322, 23 (2002)

S. Yang, Y.W. Zhang, K.Y. Zeng, J. Appl. Phys. 95, 3655 (2004)

L.C. Zhang, B.C. Wei, D.M. Xing, T.H. Zhang, W.H. Li, Y. Liu, Intermetallics 15, 791 (2007)

J.D. Ferry, Viscoelastic Properties of Polymers (Wiley, New York, 1980)

R.S. Lakes, Viscoelastic Materials (Cambridge University Press, New York, 2009)

N.W. Tschoegl, I. Emri, Int. J. Polym. Mater. 18, 117 (1992)

W.H. Wang, Prog. Mater. Sci. 57, 487 (2012)

C.Q. Zhang, K.F. Yao, J. Univ. Sci. Technol. B 14, 68 (2007)

J. Sort, J. Fornell, S. Surinach, M.D. Baro, Nanosci. Nanotechnol. Lett. 2, 298 (2010)

B. Wolf, A. Richter, V. Weihnacht, Surf. Coat. Technol. 183, 141 (2004)

J. Fornell, A. Concustell, S. Surinach, W.H. Li, N. Cuadrado, A. Gebert, M.D. Baro, J. Sort, Int. J. Plast. 25, 1540 (2009)

Acknowledgements

We are grateful for financial support from the National Natural Science Foundation of China (Grant No. 50971041).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, J., Pan, Y. & Pi, J. Nanoindentation study of Cu52Zr37Ti8In3 bulk metallic glass. Appl. Phys. A 115, 305–312 (2014). https://doi.org/10.1007/s00339-013-7816-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-013-7816-y