Abstract

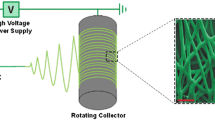

In the current study, poly(vinyl alcohol) (PVA) casted films and electrospun nanofibers blended with chitosan (CS), citronella essential oil (CEO) and/or titanium dioxide nanoparticles (TiO2) have been fabricated. Smooth surfaces of PVA, PVA/CS and PVA/CS/CEO casted films were observed while a rough surface can be seen for the TiO2 containing casted film. Electrospun nanofibers have well-defined fibrous structures with a homogeneous distribution of the additives. PVA/CS/TiO2 nanofibers have the smallest average diameter of 75 nm. The light barrier highly affected by the preparation method. Casted films transparency was affected slightly by film composition where the film containing TiO2 has the lowest value of 2.17, and the highest value was 2.77 for PVA/CS film. Electrospun nanofibers are almost opaque in the UV and visible ranges, and moreover, incorporation of TiO2 and CEO improved the UV light shielding, and thus, they can be used for protection against the light-induced oxidation processes. In general, electrospun nanofibers exhibited lower mechanical properties than those fabricated by solution casting. The highest value of tensile strength and elastic modulus was for PVA/CS/TiO2 while the highest value of elongation at break was recorded for PVA. For the thermal stability and regardless the fabrication technique, the neat PVA had the highest values of T10 and T50 where the maximum char residue was recorded for PVA/CS/TiO2. The varied fabrics’ morphological, optical, mechanical and thermal characteristics using different fabrication methods can widen the engineered possibilities to cover a wider range of applications as, for example, food packaging.

Similar content being viewed by others

References

Zahmatkeshan M, Adel M, Bahrami S et al (2019) Polymer-based nanofibers: preparation, fabrication, and applications. In: Barhoum A, Bechelany M, Makhlouf A (eds) Handbook of Nanofibers. Springer, Cham. https://doi.org/10.3390/polym14183719

Chinnappan BA, Krishnaswamy M, Xu H, Hoque ME (2022) Electrospinning of biomedical nanofibers/nanomembranes: effects of process parameters. Polymers (Basel) 614(18):3719. https://doi.org/10.3390/polym14183719

Ramakrishna S, Fujihara K, Teo W, Yong T, Ma Z, Ramaseshan R (2006) Electrospun nanofibers: solving global issues. Mater Today 9:40–50

Lu X, Wang C, Wei Y (2009) One-dimensional composite nanomaterials: synthesis by electrospinning and their applications. Small 5:2349–2370

Greiner A, Wendorff J (2007) Electrospinning: a fascinating method for the preparation of ultrathin fibers. Angew Chem Int Ed 46:5670–5703

Elsabee M, Naguib H, Morsi R (2012) Chitosan based nanofibers, review. Mater Sci Eng C 32:1711–1726

Sahatiya P, Badhulika S (2015) One-step in situ synthesis of single aligned graphene–ZnO nanofiber for UV sensing. RSC Adv 5:82481–82487

Weng B, Liu S, Tang Z, Xu Y (2014) One-dimensional nanostructure based materials for versatile photocatalytic applications. RSC Adv 25:12685–12700

Tang Z, Xu Y (2016) Heterostructured semiconductor nanowire arrays for artificial photosynthesis. Mater Horizons 3:270–282

Jiang C, Nie J, Ma G (2016) A polymer/metal core–shell nanofiber membrane by electrospinning with an electric field, and its application for catalyst support. RSC Adv 6:22996–23007

Jian M, Qian Z, Kabin L, Lei Z, Zhonghua N (2018) Piezoelectric and optoelectronic properties of electrospinning hybrid PVDF and ZnO nanofibers. Mater Res Express 5(3):035057. https://doi.org/10.1088/2053-1591/aab747

Valencia-Osorio LM, Álvarez-Láinez ML (2021) Global view and trends in electrospun nanofiber membranes for particulate matter filtration: a review. Macromol Mater Eng 306:2100278

Qasim S, Zafar M, Najeeb S, Khurshid Z, Shah A, Husain S, Rehman I (2018) Electrospinning of chitosan-based solutions for tissue engineering and regenerative medicine. Int J Mol Sci 19:407

Ding Y, Li W, Zhang F, Liu Z, Zanjanizadeh N, Liu D, Santos H (2019) Electrospun fibrous architectures for drug delivery, tissue engineering and cancer therapy. Adv Funct Mater 29:1802852

Roman S, Mangera A, Osman N, Bullock A, Chapple C, MacNeil S (2014) Developing a tissue engineered repair material for treatment of stress urinaryincontinence and pelvic organ prolapse–which cell source? Neurourol Urodyn 33(5):531–537

Wan Y, Wu H, Yu A, Wen D (2006) Biodegradable polylactide/chitosan blend membranes. Biomacromol 7:1362–1372

Kim I, Seo S, Moon H, Yoo M, Park I, Kim B, Cho C (2008) Chitosan and its derivatives for tissue engineering applications. Biotechnol Adv 26:1–21

Deepthi S, Venkatesan J, Kim S, Bumgardner J, Jayakumar R (2016) An overview of chitin or chitosan/nano ceramic composite scaffolds for bone tissue engineering. Int J Biol Macromol 93:1338–1353

Kumar S, Deepak V, Kumari M, Dutta P (2016) Antibacterial activity of diisocyanate-modified chitosan for biomedical applications. Int J Biol Macromol 84:349–353

Kumar S, Silva A, Wani M, Gil J, Sobral A (2017) Carbon dioxide capture and conversion by an environmentally friendly chitosan based meso-tetrakis(4-sulfonatophenyl) porphyrin. Carbohydr Polym 175:575–583

Elsabee MZ, Abdou ES (2013) Chitosan based edible films and coatings: a review. Mater Sci Eng, C 33:1819–1841

Raza ZA, Khalil S, Ayub A, Banat IM (2020) Recent developments in chitosan encapsulation of various active ingredients for multifunctional applications. Carbohydr Res 492:108004

Lee C, An D, Park H, Lee D (2003) Wide spectrum antimicrobial packaging materials incorporating nisin and chitosan in the coating. Packag Technol Sci 16:99–106

Contini C, Katsikogianni M, O’Neill F, O’Sullivan M, Dowling D, Monahan F (2011) Development of active packaging containing natural antioxidants. Procedia Food Sci 1:224–228

Abdou E, Galhoum G, Mohamed E (2018) Curcumin loaded nanoemulsions/pectin coatings for refrigerated chicken fillet. Food Hydrocoll 83:445–453

Munteanu B, Paslaru E, Sdrobis A, Pricope G, Vasile C (2014) Chitosan coatings applied to polyethylene surface to obtain food-packaging materials. Cell Chem Technol 48:565–575

Jayakumar R, Prabaharan M, Nair S, Tamura H (2010) Novel chitin and chitosan nanofibers in biomedical applications. Biotechnol Adv 28(1):142–150

Kim JH, Kim JY, Lee YM, Kim KY (1992) Properties and swelling characteristics of cross‐linked poly (vinyl alcohol)/chitosan blend membrane. J Appl Polym Sci 45(10):1711–1717

Pawlak A, Mucha M (2003) Thermogravimetric and FTIR studies of chitosan blends. Thermochim Acta 396(1):153–166

Li Q, Huang L, Li H, Fang S (2010) Preparation of chitosan/polyvinyl alcohol composite scaffold at different mass ratio. Comparison of structure and characteristics. J Clin Rehabil Tissue Eng Res 14(3):477–481

Qi B, Yu A, Zhu S, Chen B, Li Y (2010) The preparation and cytocompatibility of injectable thermosensitive chitosan/poly (vinyl alcohol) hydrogel. J Huazhong U Sci-Med 30:89–93

Ardekani N, Khorraml M, Zomorodian K, Yazdanpanah S, Veisi H (2019) Evaluation of electrospun poly (vinyl alcohol)-based nanofiber mats incorporated with Zataria multiflora essential oil as potential wound dressing. Int J Biol Macromol 125:743–750

Koosha M, Raoufi M, Moravvej H (2019) One-pot reactive electrospinning of chitosan/PVA hydrogel nanofibers reinforced by halloysite nanotubes with enhanced fibroblast cell attachment for skin tissue regeneration. Colloid Surface B 179:270–279

Bano I, Arshad M, Yasin T, Ghauri M (2019) Preparation, characterization and evaluation of glycerol plasticized chitosan/PVA blends for burn wounds. Int J Biol Macromol 124:155–162

Kumar S, Krishnakumar B, Sobral A, Koh J (2019) Bio-based (Chitosan/PVA/ZnO) nanocomposites film: thermally stable and photoluminescence material for removal of organic dye. Carbohydr Polym 205:559–564

Habiba U, Lee J, Joo T, Ang B, Afifi A (2019) Degradation of methyl orange and congo red by using chitosan/polyvinyl alcohol/TiO2 electrospun nanofibrous membrane. Int J Biol Macromol 131:821–827

Habiba U, Siddique T, Talebian S, Lee J, Salleha A, Angd B, Afifi A (2017) Effect of deacetylation on property of electrospun chitosan/PVA nanofibrous membrane and removal of methyl orange, Fe(III) and Cr(VI) ions. Carbohydr Polym 177:32–39

Loay A, Dawood H (2017) Active chitosan/PVA with ascorbic acid and berry quality of ‘superior seedless’ grapes. Sci Hortic 224:286–292

Koosha M, Hamedi S (2019) Intelligent chitosan/PVA nanocomposite films containing black carrot anthocyanin and bentonite nanoclays with improved mechanical, thermal and antibacterial properties. Prog Org Coat 127:338–347

Hajji S, Younes I, Affes S, Boufi S, Nasri M (2018) Optimization of the formulation of chitosan edible coating supplemented with carotenoproteins and their use for extending strawberries postharvest life. Food Hydrocoll 83:375–392

Wen P, Zhu D, Wu H, Zong M, Jing Y, Han S (2016) Encapsulation of cinnamon essential oil in electrospun nanofibrous film for active food packaging. Food Control 59:366–376

Ardekani N, Khorram M, Zomorodian K, Yazdanpanah S, Veisi H, Veisi H (2019) Evaluation of electrospun poly (vinyl alcohol)-based nanofiber mats incorporated with Zataria multiflora essential oil as potential wound dressing. Int J Biol Macromol 125:743–750

Mishraa S, Ferreirab J, Kannan S (2015) Mechanically stable antimicrobial chitosan–PVA–silvernanocomposite coatings deposited on titanium implants. Carbohydr Polym 121:37–48

Hosseini S, Nahvi Z, Zandi M (2019) Antioxidant peptide-loaded electrospun chitosan/poly(vinyl alcohol) nanofibrous mat intended for food biopackaging purposes. Food Hydrocoll 89:637–648

Puvaca N, Milenkovic J, Coghill TJ et al (2021) Antimicrobial activity of selected essential oils against selected pathogenic bacteria: in vitro study. Antibiotics 10:546

Daniela G, Elena G, Alina R et al (2022) Essential oils as antimicrobial active substances in wound dressings. Materials 15(19):6923

Faiza M, Rezwan M, Sadia A (2022) Biological & insecticidal effect of citronella oil a short review. Clin Med Health Res J 2(6):261–265

Wong K, Signal F, Campion S, Motion R (2005) Citronella as an insect repellent in food packaging. J Agric Food Chem 53(11):4633–4636

Akhila A (2009) Essential oil-bearing grasses: the genus cymbopogon. CRC Press, New York, pp 110–113

Dorneanu P, Airinei A, Homocianu M, Olaru N (2015) Photophysical and surface characteristics of electrospun polysulfone/nickel fibers. Mater Res Bull 6:306–311

Ganjkhanlou Y, Moghaddam A, Hosseini S, Nazari T, Gazmeh A, Badraghi J (2014) Application of image analysis in the characterization of electrospun nanofibers. Iran J Chem Chem Eng 33:37–45

Fei P, Shi Y, Zhou M, Cai J, Tang S, Xiong H (2013) Effects of nano-TiO2 on the properties and structures of starch/poly (ε-caprolactone) composites. J Appl Polym Sci 130(6):4129–4136

Mirjalili B, Bamoniri A, Akbari A, Taghavinia N (2011) Nano-TiO2: an eco-friendly and re-usable catalyst for the synthesis of 14-aryl or alkyl-14H-dibenzo [a, j] xanthenes. J Iran Chem Soc 8(1):S129–S134

Zolfi M, Khodaiyan F, Mousavi M, Hashemi M (2014) Development and characterization of the kefiran-whey protein isolate-TiO2 nanocomposite films. Int J Biol Macromol 65:340–345

Peter A, Mihaly-Cozmuta L, Mihaly-Cozmuta A, Nicula C, Ziemkowska W, Basiak D, Danciu V, Vulpoi A, Baia L, Falup A, Craciun G, Ciric A, Begea M, Kiss C, Vatuiu D (2016) Changes in the microbiological and chemical characteristics of white bread during storage in paper packages modified with Ag/TiO2–SiO2, Ag/N–TiO2 or Au/TiO2. Food Chem 197:790–798

Roilo D, AdaMaestri C, Scarpa M, Bettotti P, Checchetto R (2018) Gas barrier and optical properties of cellulose nanofiber coatings with dispersed TiO2 nanoparticles. Surf Coat Technol 343:131–137

Alizadeh-Sani M, Khezerlou A, Ehsani A (2018) Fabrication and characterization of the bionanocomposite film based on whey protein biopolymer loaded with TiO2 nanoparticles, cellulose nanofibers and rosemary essential oil. IND CROP PROD 124:300–315

Chaúque E, Adelodun A, Dlamini L, Greyling C, Ray S, Ngila J (2017) Synthesis and photocatalytic application of TiO2 nanoparticles immobilized on polyacrylonitrile nanofibers using EDTA chelating agents. Mater Chem Phys 192:108–124

Song M, Pan C, Chen C, Li J, Wang X, Gu Z (2008) The application of new nanocomposites: enhancement effect of polylactide nanofibers/nano-TiO2 blends on biorecognition of anticancer drug daunorubicin. Appl Surf Sci 255(2):610–612

Cazon P, Vazquez M, Velazquez G (2018) Cellulose-glycerol-polyvinyl alcohol composite films for food packaging: Evaluation of water adsorption, mechanical properties, light-barrier properties and transparency. Carbohydr Polym 195:432–443

Nasikhudin DM, Kusumaatmaja A, Triyana K (2016) Preparation of PVA/chitosan/TiO2 nanofibers using electrospinning method. Advances of science and technology for society. AIP Conf Proc 1755:150002-1–150002-6

Nasikhudin IE, Diantoro M, Kusumaatmaja A, Triyana K (2017) Preparation of PVA/TiO2 composites nanofibers by using electrospinning method for photocatalytic degradation. Mater Sci Eng 202:012011

Zhang X, Xiao G, Wang Y, Zhao Y, Su H, Tan T (2017) Preparation of chitosan-TiO2 composite film with efficient antimicrobial activities under visible light for food packaging applications. Carbohydr Polym 169:101–107

Guo J, Ge L, Li X, Mu C, Li D (2014) Periodate oxidation of xanthan gum and its crosslinking effects on gelatin-based edible films. Food Hydrocoll 39:243–250

Tijing L, Park C, Choi W, Ruelo M, Amarjargal A, Pant H, Im I, Kim C (2013) Characterization and mechanical performance comparison of multiwalled carbon nanotube/polyurethane composites fabricated by electrospinning and solution casting. Compos B Eng 44:613–619

Kukreja T, Chauhan R, Choe S, Kundu P (2003) Effect of the doses and nature of vegetable oil on carbon black/rubber interactions: studies on castor oil and other vegetable oils. J Appl Polym Sci 87:1574–1578

Can E, Wool R, Küsefoğlu S (2006) Soybean and castor-oil-based thermosetting polymers: mechanical properties. J Appl Polym Sci 102:1497–1504

Maltl S, Lopez B (1992) Tensile properties of polypropylene/kaolin composites. J. Appl. Polym. Sci. 44:353–360

Bhasney S, Patwa R, Kumar A, Katiya V (2017) Plasticizing effect of coconut oil on morphological, mechanical, thermal, rheological, barrier, and optical properties of poly(lactic acid): a promising candidate for food packaging. J Appl Polym Sci 134:45390

Nieto J, Peniche-Covas C, Padron G (1991) Characterization of chitosan by pyrolysis mass-spectrometry, thermal-analysis and differential scanning calorimetry. Thermochim Acta 176:63–68

Vinayak VN, Naganagouda G, Deepak K, Saraswati MP, Ravindra CB (2019) Thermal and tensile properties study of 4-hydroxycoumarin doped polyvinyl alcohol/chitosan blend films. Chem Data Collect 23:100257

Budrugeac P (2008) Kinetics of the complex process of thermo-oxidative degradation of poly(vinyl alcohol). J Therm Anal Calorim 92:291–296

Jabeen S, Kausar A, Saeed S, Muhammad B, Gul S (2016) Poly(vinyl alcohol) and chitosan blend cross-linked with bis phenol-F diglycidyl ether: mechanical. Thermal Water Absorpt Invest J Chinese Adv Mater Soc 4:211–227

Marija B, Zoran V, Milena T, Scott P, Nataša M, Jovan M (2012) The influence of shaped TiO2 nanofillers on the thermal properties of poly(vinyl alcohol). J Serb Chem Soc 77(5):699–714

Hu S, Song L, Pan H, Hu Y (2013) Effect of a novel chitosan-based flame retardant on thermal and flammability properties of polyvinyl alcohol. J Therm Anal Calorim 112:859–864

Tongnuanchan P, Benjakul S, Prodpran T (2012) Properties and antioxidant activity of fish skin gelatin film incorporated with citrus essential oils. Food Chem 134:1571–1579

Zhixiang C, Zifeng Z, Luyin L, Junhui Si, Qianting W, Xiangfang P, Wenzhe C (2017) Electrospinning and crosslinking of polyvinyl alcohol/chitosan composite nanofiber for transdermal drug delivery. Adv Polym Technol 37(6):1–13

Jammula RK, Abhishek R, Debargha G, Madri MM, Satyanarayana SV, Madhu GM (2015) Enhanced mechanical properties of polyvinyl alcohol composite films containing copper oxide nanoparticles as filler. Polym Bull 2015(72):2033–2047

Bin L, Yang Z, Yingzi Y, Wen Q, Xiaoxuan W, Baoping L, Yanli W, Guochang S (2016) Synthesis, characterization, and antibacterial activity of chitosan/TiO2 nanocomposite against Xanthomonas oryzae pv. oryzae. Carbohydr Polym 152(5):825–831

Liangfan Qu, Guiyun C, Shuang D, Yaoxing H, Zhonglin Y, Shuhong Li, Ye C (2019) Improved mechanical and antimicrobial properties of zein/chitosan films by adding highly dispersed nano-TiO2. Ind Crops Prod 130:450–458

Augustine A, Józef HT, Sabu T, Sreeraj G (2020) Preparation, characterization and antimicrobial activity of polyvinyl alcohol/gum arabic/chitosan composite films incorporated with black pepper essential oil and ginger essential oil. Int J Biol Macromol 151:366–375

Elio GER, José HHM, Jesús AED (2020) Development of a chitosan/PVA/TiO2 nanocomposite for application as a solid polymeric electrolyte in fuel cells. Polymers 2020(12):1691

Koosha M, Mirzadeh H (2015) Electrospinning, mechanical properties, and cell behavior study of chitosan/PVA nanofibers. J Biomed Mater Res Part A 2015(103A):3081–3093

Nasikhudin DM, Ahmad K, Kuwat T (2016) Preparation of PVA/Chitosan/TiO2 nanofibers using electrospinning method. Advances of science and technology for society AIP. Conf Proc 1755:150002-1–150002-6

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abdou, E.S., Abdel-Hakim, A. & Morsi, R.E. Influence of citronella essential oil and TiO2 nanoparticles on the optical, mechanical and thermal characteristics of chitosan/poly(vinyl alcohol) blended films and nanofibers. Polym. Bull. 81, 7943–7961 (2024). https://doi.org/10.1007/s00289-023-05081-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-023-05081-0