Abstract

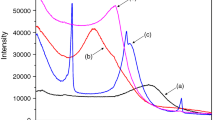

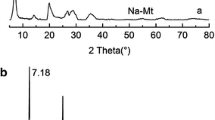

In this work, montmorillonite clay mineral (Mt) was modified with different amounts of polyethyleneimine (PEI) to obtain two new adsorbents that were used to remove tannic acid (TA) from aqueous solutions. Raw Mt and PEI-modified Mt particles, named MtPEI1 (Mt modified with 0.2% w/w PEI solution) and MtPEI4 (Mt modified with 0.8% w/w PEI solution), were characterized by infrared spectroscopy (FTIR), X-ray diffractometry (XRD), thermogravimetric analysis coupled spectroscopy mass (TG/MS), scanning electron microscopy (SEM), surface area analyses (BET), and zeta potential (ZP). Several parameters such as composition and morphology of PEI-modified Mt particles, pH, temperature, kinetic, isotherms and thermodynamic properties were used to investigate the TA adsorption process. The experimental results showed that MtPEI4 possesses higher PEI content and crystallite size than MtPEI1. The maximum adsorption capacity of MtPEI1 and MtPEI4 was found to 426.3 and 790.7 mg g−1, respectively. Adsorption kinetics showed that the TA adsorption behavior followed the pseudo-second-order model. The adsorption isotherms were better fitted by Sips model. The obtained thermodynamic parameters indicated that the TA adsorption process is spontaneous and entropy-driven.

Similar content being viewed by others

References

Chang MY, Juang RS (2004) Adsorption of tannic acid, humic acid, and dyes from water using the composite of chitosan and activated clay. J Colloid Interf Sci 278:18–25. https://doi.org/10.1016/j.jcis.2004.05.029

Ghouas H, Haddou B, Kameche M, Canselier JP, Gourdon C (2016) Removal of tannic acid from aqueous solution by cloud point extraction and investigation of surfactant regeneration by microemulsion extraction. J Surfactants Deterg 19:57–66. https://doi.org/10.1007/s11743-015-1764-9

Liu F, Guo Z, Zheng S, Xu Z (2012) Adsorption of tannic acid and phenol on mesoporous carbon activated by CO2. Chem Eng J 183:244–252. https://doi.org/10.1016/j.cej.2011.12.069

Anirudhan TS, Ramachandran M (2006) Adsorptive removal of tannin from aqueous solutions by cationic surfactant-modified bentonite clay. J Colloid Interf Sci 299:116–124. https://doi.org/10.1016/j.jcis.2006.01.056

Daikh S, Ouis D, Benyoucef A, Mouffok B (2022) Equilibrium, kinetic and thermodynamic studies for evaluation of adsorption capacity of a new potential hybrid adsorbent based on polyaniline and chitosan for acetaminophen. Chem Phys Lett 798:1–12. https://doi.org/10.1016/j.cplett.2022.139565

Lahreche S, Moulefera I, El Kebir A, Sabantina L, Kaid M, Benyoucef A (2022) Application of activated carbon adsorbents prepared from prickly pear fruit seeds and a conductive polymer matrix to remove congo red from aqueous solutions. Fibers 10:1–19. https://doi.org/10.3390/fib10010007

Ma A, Zheng X, Li K, Omran M, Chen G (2021) The adsorption removal of tannic acid by regenerated activated carbon from the spent catalyst of vinyl acetate synthesis. J Mater Res Tech 10:697–708. https://doi.org/10.1016/j.jmrt.2020.12.066

Wang J, Zheng S, Liu J, Xu Z (2010) Tannic acid adsorption on amino-functionalized magnetic mesoporous silica. Chem Eng J 165:10–16. https://doi.org/10.1016/j.cej.2010.08.066

Liou T-H, Wang S-Y, Lin Y-T, Yang S (2022) Sustainable utilization of rice husk waste for preparation of ordered nanostructured mesoporous silica and mesoporous carbon: characterization and adsorption performance. Colloid Surface A 636:1–13. https://doi.org/10.1016/j.colsurfa.2021.128150

Jung C, Phal N, Oh J, Chu KH, Jang M, Yoon Y (2015) Removal of humic and tannic acids by adsorption-coagulation combined systems with activated biochar. J Hazard Mater 300:808–814. https://doi.org/10.1016/j.jhazmat.2015.08.025

Chen J, Li H, Li J, Chen F, Lan J, Hou H (2021) Efficient removal of tetracycline from water by tannic acid-modified rice straw-derived biochar: kinetics and mechanisms. J Mol Liq 340:1–10. https://doi.org/10.1016/j.molliq.2021.117237

Chong Y, Liu K, Liu Y, Wang J, Qiao W, Ling L, Long D, Bai Z (2017) Highly efficient removal of bulky tannic acid by millimeter-sized nitrogen-doped mesoporous carbon beads. AIChE J 63:3016–3025. https://doi.org/10.1002/aic.15601

Tangarfa M, Hassani NSA, Alaoui A (2019) Behavior and mechanism of tannic acid adsorption on the calcite surface: isothermal, kinetic, and thermodynamic studies. ACS Omega 4:19647–19654. https://doi.org/10.1021/acsomega.9b02259

Zhang M, Xiao C, Yan X, Chen S, Wang C, Luo R, Qi J, Sun X, Wang L, Li J (2020) Efficient removal of organic pollutants by metal-organic framework derived Co/C Yolk-shell nanoreactors: size-exclusion and confinement effect. Envir Sci Tech 54:10289–10300. https://doi.org/10.1021/acs.est.0c00914

Liu J, Wei Y, Chang M, Wang N, Wang D, Wang JX (2022) Rapid construction of hierarchically porous metal–organic frameworks by a spray-drying strategy for enhanced tannic acid adsorption. AIChE J 68:1–13. https://doi.org/10.1002/aic.17522

Moreno-Castilla C, López-Ramón MV, Pastrana-Martínez LM, Álvarez-Merino MA, Fontecha-Cámara MA (2012) Competitive adsorption of the herbicide fluroxypyr and tannic acid from distilled and tap water on activated carbons and their thermal desorption. Adsorption 18:173–179. https://doi.org/10.1007/s10450-012-9391-5

Lawal AA, Hassan MA, Farid MAA, Yasim-Anuar TAT, Samsudin MH, Yusoff MZM, Zakaria MR, Mokhtar MN, Shirai Y (2021) Adsorption mechanism and effectiveness of phenol and tannic acid removal by biochar produced from oil palm frond using steam pyrolysis. Environ Pollut 269:1–10. https://doi.org/10.1016/j.envpol.2020.116197

Sarici-Özdemir Ç, Önal Y (2010) Equilibrium, kinetic and thermodynamic adsorptions of the environmental pollutant tannic acid onto activated carbon. Desalination 251:146–152. https://doi.org/10.1016/j.desal.2009.09.133

Li Y, Zhai Y, Zhang P, Wang X, Cui H, Li J, Liu L, Zhao H, Song J (2019) Synthesis of titania coated magnetic activated carbon for effective photodegradation of tannic acid in aqueous solution. Colloid Surf A 563:141–147. https://doi.org/10.1016/j.colsurfa.2018.11.025

Lim A, Chew JJ, Ngu LH, Ismadji S, Khaerudini DS, Sunarso J (2020) Synthesis, Characterization, adsorption isotherm, and kinetic study of oil palm trunk-derived activated carbon for tannin removal from aqueous solution. ACS Omega 5:28673–28683. https://doi.org/10.1021/acsomega.0c03811

An JH, Dultz S (2007) Adsorption of tannic acid on chitosan-montmorillonite as a function of pH and surface charge properties. Appl Clay Sci 36:256–264. https://doi.org/10.1016/j.clay.2006.11.001

Rasheed U, Ain QU, Yaseen M, Yao X, Liu B (2021) Synthesis and characterization of tannic acid pillared bentonite composite for the efficient adsorption of aflatoxins. Colloid Surface B 202:1–11. https://doi.org/10.1016/j.colsurfb.2021.111679

Deng Y, Wang L, Hu X, Liu B, Wei Z, Yang S, Sun C (2012) Highly efficient removal of tannic acid from aqueous solution by chitosan-coated attapulgite. Chem Eng J 181–182:300–306. https://doi.org/10.1016/j.cej.2011.11.082

Teng Y, Liu Z, Yao K, Song W, Sun Y, Wang H, Xu Y (2019) Preparation of attapulgite/CoFe2O4 magnetic composites for efficient adsorption of tannic acid from aqueous solution. Int J Env Res Pub He 16:1–17. https://doi.org/10.3390/ijerph16122187

Wu J, Chen J (2013) Adsorption characteristics of tannic acid onto the novel protonated palygorskite/chitosan resin microspheres. J Appl Polym Sci 127:1765–1771. https://doi.org/10.1002/app.37787

Shi L, Zhang D, Zhao J, Xue J, Yin M, Liang A, Pan B (2021) New insights into the different adsorption kinetics of gallic acid and tannic acid on minerals via 1H NMR relaxation of bound water. Sci Total Environ 767:1–7. https://doi.org/10.1016/j.scitotenv.2020.144447

Balbino TAC, Bellato CR, da Silva AD, Neto JOM, Ferreira SO (2020) Preparation and evaluation of iron oxide/hydrotalcite intercalated with dodecylsulfate/β-cyclodextrin magnetic organocomposite for phenolic compounds removal. Appl Clay Sci 193:1–12. https://doi.org/10.1016/j.clay.2020.105659

Chen B (2004) Polymer-clay nanocomposites: an overview with emphasis on interaction mechanisms. Brit Ceram T 103:241–249. https://doi.org/10.1179/096797804X4592

Guggenheim S, Adams JM, Bain DC, Bergaya F, Brigatti MF, Drits VA, Stanjek H (2006) Summary of recommendations of nomenclature committees relevant to clay mineralogy: report of the association internationale pour l’Etude des Argiles (AIPEA) nomenclature committee for 2006. Clay Clay Miner 54:61–772. https://doi.org/10.1346/CCMN.2006.0540610

Yang JH, Lee JH, Ryu HJ, Elzatahry AA, Alothman ZA, Choy JH (2016) Drug–clay nanohybrids as sustained delivery systems. Appl Clay Sci 130:20–32. https://doi.org/10.1016/j.clay.2016.01.021

Mukhopadhyay R, Bhaduri D, Sarkar B, Rusmin R, Hou D, Khanam R, Sarkar S, Kumar BJ, Vithanage M, Bhatnagar A, Ok YS (2020) Clay–polymer nanocomposites: progress and challenges for use in sustainable water treatment. J Hazard Mater 383:1–17. https://doi.org/10.1016/j.jhazmat.2019.121125

Nadali A, Khoobi M, Nabizadeh R, Naseri S, Mahvi AH (2016) Performance evaluation of montmorillonite and modified montmorillonite by polyethyleneimine in removing arsenic from water resources. Desalin Water Treat 57:21645–21653. https://doi.org/10.1080/19443994.2015.1131630

Jiang GJ, Hwu JM, Pan WP, Xie W, Gao ZM (2002) The characterization of organic modified clay and clay-filled PMMA nanocomposite. J Appl Polym Sci 83:1702–1710. https://doi.org/10.1002/app.10093

Fan M, Wang R, Jia S, Xing H, Yang Q, Jia Z (2018) Controllable synthesis of iron nanoparticles on polyethylenimine-modified montmorillonite: dependence on the amine protonation extent. Appl Clay Sci 162:418–427. https://doi.org/10.1016/j.clay.2018.06.040

Celestino GG, Henriques RR, Shiguihara AL, Constantino VRL, Melo RS, Amim Júnior J (2019) Adsorption of gallic acid on nanoclay modified with poly (diallyldimethylammonium chloride). Environ Sci Pollut R 26:28444–28454. https://doi.org/10.1007/s11356-018-3505-x

Henriques RR, Soares BG (2021) Sepiolite modified with phosphonium ionic liquids as anticorrosive pigment for epoxy coatings. Appl Clay Sci 200:1–9. https://doi.org/10.1016/j.clay.2020.105890

Avalos F, Ortiz JC, Zitzumbo R, López-Manchado MA, Verdejo R, Arroyo M (2009) Phosphonium salt intercalated montmorillonites. Appl Clay Sci 43:27–32. https://doi.org/10.1016/j.clay.2008.07.008

Öztekin N, Alemdar A, Gungor N, Erim FB (2002) Adsorption of polyethyleneimine from aqueous solutions on bentonite clays. Mater Lett 55:73–76. https://doi.org/10.1016/S0167-577X(01)00622-X

Sun Y, Wu Y, Fu Y, Yang C, Jiang J, Yan G, Hu J (2021) Rapid and high selective removal of Hg(II) ions using tannic acid cross-linking cellulose/polyethyleneimine functionalized magnetic composite. Int J Biol Macromol 182:1120–1129. https://doi.org/10.1016/j.ijbiomac.2021.04.091

Cai H, An X, Cui J, Li J, Wen S, Li K, Shi X (2013) Facile hydrothermal synthesis and surface functionalization of polyethyleneimine-coated iron oxide nanoparticles for biomedical applications. ACS Appl Mater Interfaces 5:1722–1731. https://doi.org/10.1021/am302883m

Curtis KA, Miller D, Millard P, Basus S, Horkay F, Chandran PL (2016) Unusual salt and pH induced changes in polyethylenimine solutions. PLoS ONE 11:102–110. https://doi.org/10.1371/journal.pone.0158147

Gao B, Jiang P, Lei H (2006) Studies on adsorption property of novel composite adsorption material PEI/SiO2 for uric acid. Mater Lett 60:3398–3404. https://doi.org/10.1016/j.matlet.2006.03.086

Gao J, Sun SP, Zhu WP, Chung TS (2014) Polyethyleneimine (PEI) cross-linked P84 nanofiltration (NF) hollow fiber membranes for Pb2+ removal. J Membrane Sci 452:300–310. https://doi.org/10.1016/j.memsci.2013.10.036

Li Z, Pan Z, Wang Y (2020) Mechanochemical preparation of ternary polyethyleneimine modified magnetic illite/smectite nanocomposite for removal of Cr(VI) in aqueous solution. Appl Clay Sci 198:1–10. https://doi.org/10.1016/j.clay.2020.105832

Wang W, Xiao J, Wei X, Ding J, Wang X, Song C (2014) Development of a new clay supported polyethylenimine composite for CO2 capture. Appl Energ 113:334–341. https://doi.org/10.1016/j.apenergy.2013.03.090

Roth EA, Agarwal S, Gupta RK (2013) Nanoclay-based solid sorbents for CO2 capture. Energ Fuel 27:4129–4136. https://doi.org/10.1021/ef302017m

Lutkenhaus JL, Olivetti EA, Verploegen EA, Cord BM, Sadoway DR, Hammond PT (2007) Anisotropic structure and transport in self-assembled layered polymer-clay nanocomposites. Langmuir 23:8515–8521. https://doi.org/10.1021/la700432p

Zhou X, Fu Q, Zhang Z, Fang Y, Wang Y, Wang F, Song Y, Pittman CU, Wang Q (2021) Efficient flame-retardant hybrid coatings on wood plastic composites by layer-by-layer assembly. J Clean Prod 321:1–9. https://doi.org/10.1016/j.jclepro.2021.128949

Cui Y, van Duijneveldt JS (2010) Adsorption of polyetheramines on montmorillonite at high pH. Langmuir 26:17210–17217. https://doi.org/10.1021/la103278v

Fayazi M, Ghanbarian M (2020) One-pot hydrothermal synthesis of polyethylenimine functionalized magnetic clay for efficient removal of noxious Cr(VI) from aqueous solutions. SILICON 12:125–134. https://doi.org/10.1007/s12633-019-00105-9

Larraza I, Lopez-Gonzalez M, CORRALES T, MARCELO G, (2012) Hybrid materials: magnetite–polyethylenimine–montmorillonite as magnetic adsorbents for Cr (VI) water treatment. J Colloid Interf Sci 385:24–33. https://doi.org/10.1016/j.jcis.2012.06.050

Chen Q, Zhu R, Zhu Y, Liu J, Zhu L, Ma L, Chen M (2016) Adsorption of polyhydroxy fullerene on polyethylenimine-modified montmorillonite. Appl Clay Sci 132–133:412–418. https://doi.org/10.1016/j.clay.2016.07.007

Carleer R, Reggers G, Ruysen M, Mullens J (1998) TG-MS analysis as tool for the evaluation of clay mixtures. Thermochim Acta 323:169–178. https://doi.org/10.1016/S0040-6031(98)00500-0

Vazquez A, López M, Kortaberria G, Martín L, Mondragon I (2008) Modification of montmorillonite with cationic surfactants. Thermal and chemical analysis including CEC determination. Appl Clay Sci 41:24–36. https://doi.org/10.1016/j.clay.2007.10.001

Vartiainen J, Tuominen M, Nattinen K (2009) Bio-hybrid nanocomposite coatings from sonicated chitosan and nanoclay. J Appl Polym Sci 116:3638–3647. https://doi.org/10.1002/app.31922

Galindo R, López-Delgado A, Padilla I, Yates M (2015) Synthesis and characterisation of hydrotalcites produced by an aluminium hazardous waste: a comparison between the use of ammonia and the use of triethanolamine. Appl Clay Sci 115:115–123. https://doi.org/10.1016/j.clay.2015.07.032

Peng Y, Chen D, Ji J, Kong Y, Wan H, Yao C (2013) Chitosan-modified palygorskite: preparation, characterization and reactive dye removal. Appl Clay Sci 74:81–86. https://doi.org/10.1016/j.clay.2012.10.002

Ho YS, McKay G (1998) Sorption of dye from aqueous solution by peat. Chem Eng J 70(2):115–124. https://doi.org/10.1016/S0923-0467(98)00076-1

Weber WJ, Morris JC (1963) Kinetics of adsorption on carbon from solutions. J Sanit Eng Div Am Soc Civ Eng 89:31–60. https://doi.org/10.1061/JSEDAI.0000430

Qiu H, Lv L, Pan BC, Zhang QJ, Zhang WM, Zhang QX (2009) Critical review in adsorption kinetic models. J Zhejiang Univ-Sc A 10:716–724. https://doi.org/10.1631/jzus.A0820524%3e

Moussout H, Ahlafi H, Aazza M, Maghat H (2018) Critical of linear and nonlinear equations of pseudo-first order and pseudo-second order kinetic models. Karbala Int J Mod Sci 4:244–254. https://doi.org/10.1016/j.kijoms.2018.04.001

Akpomie KG, Dawodu FA, Adebowale KO (2015) Mechanism on the sorption of heavy metals from binary-solution by a low cost montmorillonite and its desorption potential. Alex Eng J 54:757–767. https://doi.org/10.1016/j.aej.2015.03.025

Hameed BH, Ahmad AA, Aziz N (2007) Isotherms, kinetics and thermodynamics of acid dye adsorption on activated palm ash. Chem Eng J 133:195–203. https://doi.org/10.1016/j.cej.2007.01.032

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40:1361–1403. https://doi.org/10.1021/ja02242a004

Freundlich H (1906) Uber die adsorption in losungen (adsorption in solution). Z Phys Chem 57:384–470. https://doi.org/10.1515/zpch-1907-5723

Foo KY, Hameed BH (2010) Insights into the modeling of adsorption isotherm systems. Chem Eng J 156:2–10. https://doi.org/10.1016/j.cej.2009.09.013

Huang J, Liu Y, Wang X (2008) Selective adsorption of tannin from flavonoids by organically modified attapulgite clay. J Hazard Mater 160:382–387. https://doi.org/10.1016/j.jhazmat.2008.03.008

Shi P, Hu X, Duan M (2021) A UIO-66/tannic acid/chitosan/polyethersulfone hybrid membrane-like adsorbent for the dynamic removal of dye and Cr (VI) from water. J Clean Prod 290:1–10. https://doi.org/10.1016/j.jclepro.2021.125794

Singh S, Kushwaha JP (2014) Tannic acid adsorption/desorption study onto/from commercial activated carbon. Desalin Water Treat 52:3301–3311. https://doi.org/10.1080/19443994.2013.802259

Cai J, Jiang L, Wei H, Wang C, Yu L, Zhang L (2019) Preparation of carbon/cobalt composite from phenolic resin and ZIF-67 for efficient tannic acid adsorption. Micropor Mesopor Mat 287:9–17. https://doi.org/10.1016/j.micromeso.2019.05.046

Cao Y, Qi X, Yan H (2020) Selective adsorption of tannins over small polyphenols on cross-linked polyacrylamide hydrogel beads and their regeneration with hot water. React Funct Polym 146:1–7. https://doi.org/10.1016/j.reactfunctpolym.2019.104398

Wei W, Li J, Han X, Yao Y, Zhao W, Han R, Li S, Zhang Y, Zheng C (2021) Insights into the adsorption mechanism of tannic acid by a green synthesized nano-hydroxyapatite and its effect on aqueous Cu(II) removal. Sci Total Environ 778:1–13. https://doi.org/10.1016/j.scitotenv.2021.146189

Acknowledgements

The authors acknowledge the Brazilian funding agency FAPERJ for its financial support and Ruan R. Henriques thanks CAPES for scholarship.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Henriques, R.R., Shiguihara, A.L., Constantino, V.R.L. et al. Adsorption behavior of tannic acid on polyethylenimine-modified montmorillonite with different morphologies. Polym. Bull. 80, 10139–10163 (2023). https://doi.org/10.1007/s00289-022-04550-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04550-2