Abstract

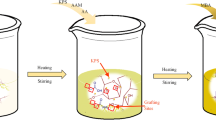

This study involves the development of sustainable technology/methodology for the production, characterization and numerical calculation of highly effective multi-component anti-hail seeding reagents (seeding composites) based on silver iodide and iodide of an alkali metal, homogenized in synthetic or bio polyurethane binder. Polyurethane-based seeding composites are produced via casting method and the results of uniaxial tensile tests, hardness and dynamic-mechanical analysis show that applied technique is more suitable compared to the conventional dry homogenization of the seeding active agents. Lower viscosity, uniform powdered seeding agents distribution and improved mechanical properties, e.g. higher tensile strength (5.05 MPa) and Shore A hardness (89 ShA) are achieved using castor oil as bio-polymer binder, compared to the synthetic polymer hydroxyl terminated poly(butadiene). In addition, significantly higher glass transition temperature obtained for seeding composite with castor oil as polymer binder indicating higher density and branched polymer network. Numerical models of the convective clouds are used to determine composition and mass of seeding agent which gives the best results concerning hail suppression or rain intensification. Results show that composite seeding reagents which contain silver iodide and potassium iodide in a molar ratio of 1:2 upon combustion generate freezing nuclei which are active above 0 °C, providing the most effective cloud seeding with 10.53% hail accumulations suppression.

Graphical abstract

Similar content being viewed by others

References

Mijatovic M (2016) Why Doesn’ T hail protection in Serbia work?

Kovačević N (2019) Hail suppression effectiveness for varying solubility of natural aerosols in water. Meteorol Atmos Phys 131:585–599. https://doi.org/10.1007/s00703-018-0587-4

Abshaev MT, Sulakvelidze GK, Burtsev II, Fedchenko LM, Jekamukhov MK, Abshaev AM, Kuznetsov BK, Malkarova AM, Tebuev AD, Nesmeyanov PA, Shakirov IN, Shevela GF (2006) Development of rocket and artillery technology for hail suppression M.T. In: Bojkov RD (ed) Achievements in weather modification. Department of Atmospheric Studies, Abu Dhabi, UAE, pp 117–139

Mesinger F, Mesinger N (1992) Has hail suppression in Eastern Yugoslavia led to a reduction in the frequency of hail? J Appl Meteorol 31:104–111

Kumar, P., Jayakumar, D., Pawar, S.: Anti-Hail Rocket (OLASTRA A-1) with Ejectable Pyrotechnique Cartridges. 3: 143–152

Kovačević N, Veljovic K (2018) Impact of drizzle-sized cloud particles on production of precipitation in hailstorms: a sensitivity study. Atmosphere (Basel). https://doi.org/10.3390/atmos9010013

Mentus S (1994) Method and composition for precipitation of atmosfpheric water

Burkardt LA, Finnegan WG, Odencrantz FK, St Amand P, Stanifer CD (1971) Method of controlling weather, https://patents.google.com/patent/US3915379A/en?oq=US3915379A

Fajardo C, Costa G, Ortiz LT, Nande M, Rodríguez-Membibre ML, Martín M, Sánchez-Fortún S (2016) Potential risk of acute toxicity induced by AgI cloud seeding on soil and freshwater biota. Ecotoxicol Environ Saf 133:433–441. https://doi.org/10.1016/j.ecoenv.2016.06.028

Meshalkin VP, Belyakov AV (2020) Methods used for the compaction and molding of ceramic matrix composites reinforced with carbon nanotubes. Processes 8:1–37. https://doi.org/10.3390/PR8081004

Rodić V, Dimić M, Brzić S, Gligorijević N (2016) Cast composite solid propellants with different combustion stabilizers. Sci Tech Rev 65:3–10. https://doi.org/10.5937/str1502003r

Raghu AV, Gadaginamath GS, Mathew NT, Halligudi SB, Aminabhavi TM (2007) Synthesis and characterization of novel polyurethanes based on 4,4′-[1,4-phenylenedi-diazene-2,1-diyl]bis(2-carboxyphenol) and 4,4′-[1,4-phenylenedi-diazene-2,1-diyl]bis(2-chlorophenol) hard segments. React Funct Polym 67:503–514. https://doi.org/10.1016/j.reactfunctpolym.2007.02.003

Raghu AV, Gadaginamath GS, Jawalkar SS, Halligudi SB, Aminabhavi TM (2006) Synthesis, characterization, and molecular modeling studies of novel polyurethanes based on 2,20-[ethane-1,2-diylbis(nitrilomethylylidene)]diphenol and 2,20-[hexane-1,6-diylbis(nitrilomethylylidene)] diphenol hard segments. J Polym Sci Part A Polym Chem 44:6032–6046. https://doi.org/10.1002/pola.21686

Kim KT, Dao TD, Jeong HM, Anjanapura RV, Aminabhavi TM (2015) Graphene coated with alumina and its utilization as a thermal conductivity enhancer for alumina sphere/thermoplastic polyurethane composite. Mater Chem Phys 153:291–300. https://doi.org/10.1016/j.matchemphys.2015.01.016

Raghu AV, Lee YR, Jeong HM, Shin CM (2008) Preparation and physical properties of waterborne polyurethane/ functionalized graphene sheet nanocomposites. Macromol Chem Phys 209:2487–2493. https://doi.org/10.1002/macp.200800395

McClain MS, Gunduz IE, Son SF (2019) Additive manufacturing of ammonium perchlorate composite propellant with high solids loadings. Proc Combust Inst 37:3135–3142. https://doi.org/10.1016/j.proci.2018.05.052

Rusmirović JD, Rančić MP, Pavlović VB, Rakić VM, Stevanović S, Djonlagić J, Marinković AD (2018) Cross-linkable modified nanocellulose/polyester resin-based composites: effect of unsaturated fatty acid nanocellulose modification on material performances. Macromol Mater Eng 303:1700648. https://doi.org/10.1002/mame.201700648

Williams GI, Wool RP (2000) Composites from natural fibers and soy oil resins. Appl Compos Mater 7:421–432. https://doi.org/10.1023/A:1026583404899

Li M, Xia J, Mao W, Yang X, Xu L, Huang K, Li S (2017) Preparation and properties of castor oil-based dual cross-linked polymer networks with polyurethane and polyoxazolidinone structures. ACS Sustain Chem Eng 5:6883–6893. https://doi.org/10.1021/acssuschemeng.7b01103

Tran NB, Pham QT (1997) Castor oil-based polyurethanes: 2. Tridimensional polyaddition in bulk between castor oil and diisocyanates - Gelation and determination of Fw(OH). Polymer (Guildf) 38:3307–3314. https://doi.org/10.1016/S0032-3861(96)00890-7

Seyidoglu T, Bohn MA (2015) Modelling of loss factor curves obtained by torsion-DMA of HTPB and GAP based binders manufactured with different curing agents and plasticizers. pp. 1–26

ASTM International (2014) Standard test method for tensile properties of plastics. ASTM Int. 1–17. Doi: https://doi.org/10.1520/D0638-14.1

Hsie E-Y, Farley RD, Orville HD (1980) Numerical simulation of ice-phase convective cloud seeding. J Appl Meteorol 19:950–977

Cooper WA (1974) A possible mechanism for contact nucleation. J Atmos Sci 31:1832–1837

Dey A, Kumar A, Sikder AK, Gupta M (2015) Chemically collapsible mandrel for solid rocket motor processing. J Aerosp Technol Manag 7:277–284. https://doi.org/10.5028/jatm.v7i3.494

Potassium Iodide (KI), https://www.cdc.gov/nceh/radiation/emergencies/ki.htm

Clemitson IR, Clemitson IR (2008) Castable polyurethane elastomers. CRC Press, London

Kojio K, Nakashima S, Furukawa M (2007) Microphase-separated structure and mechanical properties of norbornane diisocyanate-based polyurethanes. Polymer (Guildf) 48:997–1004. https://doi.org/10.1016/j.polymer.2006.12.057

Wong CS, Badri KH (2012) Chemical analyses of palm kernel oil-based polyurethane prepolymer. Mater Sci Appl 03:78–86. https://doi.org/10.4236/msa.2012.32012

Kalusuraman G, Siva I, Munde Y, Selvan CP, Kumar SA, Amico SC (2020) Dynamic-mechanical properties as a function of luffa fibre content and adhesion in a polyester composite. Polym Test 87:106538. https://doi.org/10.1016/j.polymertesting.2020.106538

Ornaghi HL, Bolner AS, Fiorio R, Zattera AJ, Amico SC (2010) Mechanical and dynamic mechanical analysis of hybrid composites molded by resin transfer molding. J Appl Polym Sci. https://doi.org/10.1002/app.32388

Hameed N, Sreekumar PA, Francis B, Yang W, Thomas S (2007) Morphology, dynamic mechanical and thermal studies on poly(styrene-co-acrylonitrile) modified epoxy resin/glass fibre composites. Compos Part A Appl Sci Manuf 38:2422–2432. https://doi.org/10.1016/j.compositesa.2007.08.009

Romanzini D, Lavoratti A, Ornaghi HL, Amico SC, Zattera AJ (2013) Influence of fiber content on the mechanical and dynamic mechanical properties of glass/ramie polymer composites. Mater Des 47:9–15. https://doi.org/10.1016/j.matdes.2012.12.029

Lavoratti A, Scienza LC, Zattera AJ (2016) Dynamic-mechanical and thermomechanical properties of cellulose nanofiber/polyester resin composites. Carbohydr Polym 136:955–963. https://doi.org/10.1016/j.carbpol.2015.10.008

Kovačević T, Rusmirović J, Tomić N, Marinović-Cincović M, Kamberović Ž, Tomić M, Marinković A (2017) New composites based on waste PET and non-metallic fraction from waste printed circuit boards: mechanical and thermal properties. Compos Part B Eng 127:1–14. https://doi.org/10.1016/j.compositesb.2017.06.020

Drah A, Rusmirovic J, Kovačević T, Tomić N, Bogosavljavic M, Marinkovic A (2019) Effect of surface activation of alumina particles on the performances of thermosetting-based composite materials. J Compos Mater. https://doi.org/10.1177/0021998319839133

Brzić S, Dimić M, Jelisavac L, Djonlagić J, Ušćumlić G, Bogdanov J (2015) Influence of polyglycidyl-type bonding agents on the viscoelastic properties of a carboxylterminated poly(butadiene-co-acrylonitrile)-based composite rocket propellant. Cent Eur J Energ Mater 12:307–321

Cerri S, Bohn MA, Menke K, Galfetti L (2013) Aging of HTPB/Al/AP rocket propellant formulations investigated by DMA measurements. Propellants Explos Pyrotech 38:190–198. https://doi.org/10.1002/prep.201200186

Brzic S, Jelisavac L, Galovic J, Simic D, Petkovic J (2014) Viscoelastic properties of hydroxyl-terminated poly(butadiene) based composite rocket propellants. Hem Ind 68:435–443. https://doi.org/10.2298/HEMIND130426067B

Kovačević T, Rusmirović J, Tomić N, Mladenović G, Milošević M, Mitrović N, Marinković A (2019) Effects of oxidized/treated non-metallic fillers obtained from waste printed circuit boards on mechanical properties and shrinkage of unsaturated polyester-based composites. Polym Compos 40:1170–1186. https://doi.org/10.1002/pc.24827

Feng Y, Liang H, Yang Z, Yuan T, Luo Y, Li P, Yang Z, Zhang C (2017) A solvent-free and scalable method to prepare soybean-oil-based polyols by thiol-ene photo-click reaction and biobased polyurethanes therefrom. ACS Sustain Chem Eng 5:7365–7373. https://doi.org/10.1021/acssuschemeng.7b01672

Jia R, Wang D, Huang Z, Liu X, Zhao C, Hui Z, Xu X, He X (2020) Synthesis of castor oil-based waterborne polyurethane with improved properties via adjusting PBA/CO soft segment ratio. ChemistrySelect 5:12690–12696. https://doi.org/10.1002/slct.202003710

Acknowledgements

The authors are grateful to the Ministry of Education, Science and Technological Development of the Republic of Serbia for the financial support provided, as part of the projects: Contract No. 451-03-68/2022-14/200325 and 176013.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Data availability statement

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Brzić, S., Kovačević, N., Gržetić, J. et al. Multi-component elastomeric composites based on castor oil/AgI/KI for cloud seeding: processing and modeling of reagent efficiency. Polym. Bull. 80, 4535–4553 (2023). https://doi.org/10.1007/s00289-022-04278-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04278-z