Abstract

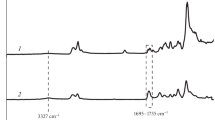

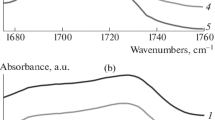

A series of cross-linked hydroxyl-terminated polyether and poly(ε-caprolactone) HTPE/PCL binders were prepared by varying the relative mass contents of PCL to HTPE. The correlations between the microstructures and macroscopic mechanical properties of HTPE/PCL binders at a wide temperature range of − 50 to 70 °C were investigated. The cross-linking network structures of HTPE/PCL binders were analyzed by Fourier transform infrared spectroscopy (FT-IR), X-ray diffraction (XRD) and low-field nuclear magnetic resonance (LF-NMR), and the universal testing machine was used to characterize the mechanical properties of HTPE/PCL binders. It is found that the influence of adding PCL on the physical cross-linking network structures is not obvious, but it reduces the degree of microphase separation. For the chemical cross-linking network structures of HTPE/PCL binders, the cross-linking density (Ve) demonstrates an increasing tendency with enhancing PCL mass content, but the molecular weight between the cross-linking points (Mc) shows an opposite change trend. The addition of PCL can improve the maximum tensile strength (σm) of HTPE/PCL binders under the wide temperature range of − 50 to 70 °C. The HTPE/PCL binder with 40 wt% PCL possesses the better mechanical properties; its σm increases from 0.63 to 0.81 MPa at 20 °C, 1.64 to 3.06 MPa at − 50 °C and 0.57 to 0.68 MPa at 70 °C separately comparing with the HTPE binder.

Similar content being viewed by others

References

Tan HM (2015) The chemistry and technology of solid rocket propellant, 1st edn. Beijing Institute of Technology Press, Beijing, p 186

Duncan ES, Margetson J (2009) A nonlinear viscoelastic theory for solid rocket propellants based on a cumulative damage approach. Propell Explos Pyrot 23:94–104

Li G, Wang Y, Jiang A, Yang M (2018) Micromechanical investigation of debonding processes in composite solid propellants. Propell Explos Pyrot 43:642–649

Zhang L, Zhi S, Shen Z (2018) Research on tensile mechanical properties and damage mechanism of composite solid propellants. Propell Explos Pyrot 43:234–240

Bhowmik D, Sadavarte VS, Pande SM, Saraswat BS (2015) An energetic binder for the formulation of advanced solid rocket propellants. Cent Eur J Energ Mater 12:145–158

Colclough ME, Desai H, Millar RW, Paul NC, Stewart MJ, Golding P (1994) Energetic polymers as binders in composite propellants and explosives. Polym Adv Technol 5:554–560

Davenas A (2003) Development of modern solid propellants. J Propul Power 19:1108–1128

Li Y, Li J, Ma S, Luo YJ (2016) Different catalytic systems on hydroxyl-terminated GAP and PET with poly-isocyanate: curing kinetics study using dynamic in situ IR spectroscopy. Int J Polym Anal Charact 21:495–503

Manu SK, Varghese TL, Mathew S, Ninan KN (2010) Studies on structure property correlation of cross-linked glycidyl azide polymer. J Appl Polym Sci 114:3360–3368

Luo YJ, Wang XQ, Ge Z (2011) Energetic polymers, 1st edn. National Defense Industry Press, Beijing, pp 144–145

Coleman MM, Lee KH, Skrovanek DJ, Painter PC (1986) Hydrogen bonding in polymers. 4. Infrared temperature studies of a simple polyurethane. Macromolecules 19:2149–2157

Luo N, Wang D, Ying SK (1997) Hydrogen-bonding properties of segmented polyether poly(urethane urea) copolymer. Macromolecules 30:4405–4409

Yarmohammadi M, Komeili S, Shahidzadeh M (2018) Studying crosslinker chemical structure effect on the tuning properties of HTPB-based polyurethane. Propell Explos Pyrot 43:156–161

Ou YP, Sun Y, Jiao Q (2018) Properties related to linear and branched network structure of hydroxyl terminated polybutadiene. e-Polymers 18:267–274

Xia M, Luo YJ, Mao KZ (2014) The Mechanism of thermal decomposition of HTPE binder and its effect on the thermal decomposition characteristics of AP. China Academic Journal Electronic Publishing House. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-HNCL201411001069.htm. Accessed 21 Nov 2014

Wang G, Fan WW, Zhang X, Zhang WB, Zhu XZ, Fan XD (2015) Synthesis of poly(ethylene oxide)-poly(tetrahydrofuran) diblock copolymer by end group protection. Polym Mater Sci Eng 31:27–30

Wang CD, Luo YJ, Xia M (2011) Synthesis of HTPE and properties of HTPE elastomers. Chin J Energ Mater 19:518–522

Kai F, Tokerud D,Biserod H, Orbekk E, Tenden S, Kaiserman M, Rodack M, Spate W, Winetrobe S, Royce B, Wallace S (2005) The hypervelocity anti-tank missile development program: rocket motor design and development. American Institute of Aeronautics and Astronautics Press. https://doi.org/10.2514/6.2005-4172. Accessed 19 June 2012

Kaiserman M, Rodack M, Spate W, Winetrobe S, Royce B, Wallace S, Biserod H, Fossumstuen K, Tokerud D (2005) An overview of the hypervelocity anti-tank missile (HATM) development program. American Institute of Aeronautics and Astronautics Press. https://doi.org/10.2514/6.2005-4171. Accessed 19 June 2012

Song XQ, Zhou JY, Wang WH, Li XH (2008) Review on HTPE propellants. Chin J Energ Mater 16:349–352

Liao LQ, Xu HX, Li YH, Pang WQ, Zhang NN, Wang JL, Liu GL (2010) Experimental study on hazard of HTPB propellants. Chin J Explos Propell 33:28–31

Yan DQ, Xu DD, Shi JG (2009) A review of solid propellant binder HTPE development and its molecular design philosophy. J Solid Rocket Technol 32:644–649

Zhang QF, Zhang JQ (2004) Research and development of insensitive solid propellants. Chin J Energ Mater 12:371–375

Mao KZ, Xia M, Luo YJ, Zhang ZJ (2012) Effect of curing agent types on properties of HTPE polyurethane elastomer films. Chin J Explos Propell 35:55–58

Millar RW, Philbin SP, Claridge RP, Hamid J (2010) Studies of novel heterocyclic insensitive high explosive compounds: pyridines, pyrimidines, pyrazines and their bicyclic analogues. Propell Explos Pyrot 29:81–92

Pagoria PF, Lee GS, Mitchell AR, Schmidt RD (2002) A review of energetic materials synthesis. Thermochimica Acta 384(1):187–204

Pang AM, Zheng J (2004) Prospect of the research and development of high energy solid propellant technology. J Solid Rocket Technol 27(4):289–293

Brunette CM, Hsu SL, Macknight WJ (1982) Hydrogen-bonding properties of hard-segment model compounds in polyurethane block copolymers. Macromolecule 15:71–77

Wang Y, Dang H, Zeng H, Bai J, Lei Y, Liu L, Li Z (2016) Properties of PCL/MDI/BDO polyurethane elastomer. Plastics 6:93–95

Wang X, Zhao H, Turng L-S, Qian L (2013) Crystalline morphology of electrospun poly(ε-caprolactone) (PCL) nanofibers. Ind Eng Chem Res 52:4939–4949

Min BS, Ko SW (2013) Characterization of segmented block copolyurethane network based on glycidyl azide polymer and polycaprolactone. Macromol Res 15:225–233

Min BS (2008) Characterization of the plasticized GAP/PEG and GAP/PCL block copolyurethane binder matrices and its propellants. Propell Explos Pyrot 33:131–138

Yilgor I, Yilgor E, Guler IG, Ward TC, Wilkes GL (2006) FTIR investigation of the influence of diisocyanate symmetry on the morphology development in model segmented polyurethanes. Polymer 47:4105–4114

Tien YI, Wei KH (2001) Hydrogen bonding and mechanical properties in segmented montmorillonite/polyurethane nanocomposites of different hard segment ratios. Polymer 42:3213–3221

Ma S, Li YJ, Li GP, Luo YJ (2017) Research on the mechanical properties and curing networks of energetic GAP/TDI binders. Cent Eur J Energ Mater 14:708–725

Chen ZS (1990) Study on properties and phase separation of segmented polyurea for different hard segment content. Polym Mater Sci Eng 3:26–31

Chen XD, Zhou NQ, Zhang H, Zhou CH, Chen RS (2008) Characterization methods for polyurethane elastomer micro-phase separated structure. Chi Elastom 18:58–65

Garbarczyk M, Grinberg F, Nestle N, Kuhn W (2001) A novel approach to the determination of the crosslink density in rubber materials with the dipolar correlation effect in low magnetic fields. J Polym Sci Polym Phys 39:2207–2216

Kuhn W, Theis I, Koeller E (1991) Network dynamics of crosslinked polymers-crosslinking, filler and aging characterized by NMR parameters. Mater Res Soc Symp Proc 33:217–223

Azoug A, Constantinescu A, Nevière R, Jacob G (2015) Microstructure and deformation mechanisms of a solid propellant using 1H NMR spectroscopy. Fuel 148:39–47

Fried E (2002) An elementary molecular-statistical basis for the Mooney and Rivlin–Saunders theories of rubber elasticity. J Mech Phys Solids 50:571–582

Li YJ, Li J, Ma S, Luo YJ (2017) Compatibility, mechanical and thermal properties of GAP/P(EO-co-THF) blends obtained upon a urethane-curing reaction. Polym Bull 74:4607–4618

Ding YZ, Hu C, Guo X, Che YY, Huang J (2014) Structure and mechanical properties of novel composites based on glycidyl azide polymer and propargyl-terminated polybutadiene as potential binder of solid propellant. J Appl Polym Sci 137:1–8

Tattersall HG, Tappin G (1966) The work of fracture and its measurement in metals, ceramics and other materials. J Mater Sci 1:296–301

Mao KZ, Ma S, Luo YJ (2016) Effect of TDI on the mechanical property and crosslinking network structure integrity. J Solid Rocket Technol 3:378–382

Chen Y, Zhang H, Fang X, Lin Y, Xu Y, Weng W (2014) Mechanical activation of mechanophore enhanced by strong hydrogen bonding interactions. Acs Macro Lett 3:141–145

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yuan, S., Jiang, S. & Luo, Y. Cross-linking network structures and mechanical properties of novel HTPE/PCL binder for solid propellant. Polym. Bull. 78, 313–334 (2021). https://doi.org/10.1007/s00289-020-03110-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-020-03110-w