Abstract

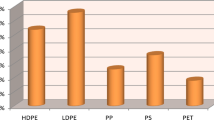

The effect of Kankara zeolite-Y-based catalyst on some physical properties of liquid fuel obtained from the pyrolysis of mixed waste plastics has been investigated. Combination of zeolite-Y, metakaolin, aluminum hydroxide and sodium silicate all synthesized from Kankara kaolin from Kankara in Katsina State, Nigeria, was used as catalysts. In this study, fifteen experiments were conducted: fourteen set of 200 g of the mixed waste plastics comprising 27 wt% HDPE, 33 wt% LDPE, 13 wt% PP, 18 wt% PS, 9 wt% PET were de-polymerized with catalyst and a set without catalyst (thermal pyrolysis) in a batch reactor. The maximum temperatures for catalyzed and thermal pyrolysis in this study are 350 °C and 490 °C, respectively. The catalyst components were characterized by XRF analysis, while their textural properties were determined from BET technique by N2 adsorption at − 196 °C. A constant catalyst-to-plastic ratio of 1:10 was used for all the catalyzed reactions. The catalyzed liquid sample with the optimum yield of 46.7 wt% was obtained using 10.49 wt%, 32.42 wt%, 27.09 wt% and 30 wt%, of zeolite-Y, metakaolin, aluminumhydroxide and sodium silicate, respectively, while the thermal pyrolysis gave a liquid yield of 66.9 wt%. Furthermore, the liquid products obtained for both thermal and catalytic cracking at optimum yield were characterized for their suitability as fuel. The properties determined were density, viscosity, fire point, and calorific value. The results suggest that catalytic pyrolysis produced liquid products whose properties are comparable to conventional fuels (gasoline and diesel oil) and more suitable for use as liquid fuel than that produced through thermal pyrolysis.

Similar content being viewed by others

References

Crawford RJ (1998) Plastics engineering. Elsevier, Amsterdam

Curcio M, Picci N (2008) Polymer in agriculture: a review. Am J Agric Biol Sci 3(1):299–314

Scott G (2013) Degradable polymers: principles and applications. Springer, New York

Al-Salem S, Antelava A, Constantinou A, Manos G, Dutta A (2017) A review on thermal and catalytic pyrolysis of plastic solid waste (PSW). J Environ Manag 197:177–198

Behera AK, Avancha S, Basak RK, Sen R, Adhikari B (2012) Fabrication and characterizations of biodegradable jute reinforced soy based green composites. Carbohyd Polym 88(1):329–335

Singh P, Sharma V (2016) Integrated plastic waste management: environmental and improved health approaches. Procedia Environ Sci 35:692–700

Lee H, Park Y-K (2018) Catalytic pyrolysis of polyethylene and polypropylene over desilicated beta and Al-MSU-F. Catalysts 8(11):501

Hafeez S, Manos G, Al-Salem S, Aristodemou E, Constantinou A (2018) Liquid fuel synthesis in microreactors. React Chem Eng 3:414–432

Wang T, Xiao F, Zhu X, Huang B, Wang J, Amirkhanian S (2018) Energy consumption and environmental impact of rubberized asphalt pavement. J Clean Prod 180:139–158

Scott G (2000) ‘Green’ polymers. Polym Degrad Stab 68(1):1–7

La Mantia F (2002) Handbook of plastics recycling. Smithers Rapra Publishing, Akron

Sharuddin SDA, Abnisa F, Daud WMAW, Aroua MK (2016) A review on pyrolysis of plastic wastes. Energy Convers Manag 115:308–326

Sim J-W, Kim S-S (2017) Recovery of polyethylene telephthalate monomer over Cu or Mn/gamma-Al2O3 catalysts. Appl Chem Eng 28(4):485–489

Lee H, Kim Y-M, Lee I-G, Jeon J-K, Jung S-C, Do Chung J, Park Y-K (2016) Recent advances in the catalytic hydrodeoxygenation of bio-oil. Korean J Chem Eng 33(12):3299–3315

Panda AK, Singh RK, Mishra D (2010) Thermolysis of waste plastics to liquid fuel: a suitable method for plastic waste management and manufacture of value-added products—a world prospective. Renew Sustain Energy Rev 14(1):233–248

Shafaghat H, Rezaei PS, Ro D, Jae J, Kim B-S, Jung S-C, Park Y-K (2017) In-situ catalytic pyrolysis of lignin in a bench-scale fixed bed pyrolyzer. J Ind Eng Chem 54:447–453

Czajczyńska D, Anguilano L, Ghazal H, Krzyżyńska R, Reynolds A, Spencer N, Jouhara H (2017) Potential of pyrolysis processes in the waste management sector. Therm Sci Eng Prog 3:171–197

Biswal B, Kumar S, Singh R (2013) Production of hydrocarbon liquid by thermal pyrolysis of paper cup waste. J Waste Manag 2013:731858. https://doi.org/10.1155/2013/731858

Chowdhury R, Sarkar A (2012) Reaction kinetics and product distribution of slow pyrolysis of Indian textile wastes. Int J Chem React Eng. https://doi.org/10.1515/1542-6580.2662

Zhang X, Lei H, Yadavalli G, Zhu L, Wei Y, Liu Y (2015) Gasoline-range hydrocarbons produced from microwave-induced pyrolysis of low-density polyethylene over ZSM-5. Fuel 144:33–42

Almeida D, Marques MDF (2016) Thermal and catalytic pyrolysis of plastic waste. Polímeros 26(1):44–51

López A, De Marco I, Caballero B, Laresgoiti M, Adrados A, Aranzabal A (2011) Catalytic pyrolysis of plastic wastes with two different types of catalysts: ZSM-5 zeolite and Red Mud. Appl Catal B 104(3–4):211–219

Auxilio AR, Choo W-L, Kohli I, Srivatsa SC, Bhattacharya S (2017) An experimental study on thermo-catalytic pyrolysis of plastic waste using a continuous pyrolyser. Waste Manag 67:143–154

Seo Y-H, Lee K-H, Shin D-H (2003) Investigation of catalytic degradation of high-density polyethylene by hydrocarbon group type analysis. J Anal Appl Pyrol 70(2):383–398

Li K, Lee SW, Yuan G, Lei J, Lin S, Weerachanchai P, Wang J-Y (2016) Investigation into the catalytic activity of microporous and mesoporous catalysts in the pyrolysis of waste polyethylene and polypropylene mixture. Energies 9(6):431

Uemichi Y, Hattori M, Itoh T, Nakamura J, Sugioka M (1998) Deactivation behaviors of zeolite and silica–alumina catalysts in the degradation of Polyethylene. Ind Eng Chem Res 37(3):867–872

Aguado J, Serrano D, San Miguel G, Castro M, Madrid S (2007) Feedstock recycling of polyethylene in a two-step thermo-catalytic reaction system. J Anal Appl Pyrol 79(1–2):415–423

Ajibola AA, Omoleye AJ, Efeovbokhan VE (2018) Catalytic cracking of polyethylene plastic waste using synthesized zeolite Y from Nigerian kaolin deposit. Appl Petrochem Res 8:211–217

Hakeem IG, Aberuagba F, Musa U (2018) Catalytic pyrolysis of waste polypropylene using Ahoko kaolin from Nigeria. Appl Petrochem Res. https://doi.org/10.1007/s13203-018-0207-8

Babalola R, Bassey EN, Brown IL, Salahudeen N (2017) Identification of kaolinite clay in five local government areas of Akwa Ibom State, Nigeria for zeolite synthesis as a way of import substitution. J Emerg Trends Eng Appl Sci 8(5):215–218

Ajayi AO, Atta AY, Aderemi BO, Adefila SS (2010) Novel method of metakaolin dealumination-preliminary investigation. J Appl Sci Res 6(10):1539–1546

Aderemi BO, Edomwonyi-Otu L, Adefila SS (2009) A new approach to metakaolin dealumination. Aust J Basic Appl Sci 3(3):2243–2248

Bawa SG, Ahmed AS, Okonkwo PC, Waziri SM (2017) Developmemt of pilot scale dealumination unit of 2.5 kg metakaolin per batch capacity. Niger J Technol 36(3):829–834

Francis AA, Fredriksen SB, Sætre KA, Tokheim L-A (2018) Experimental study of thermal and catalytic pyrolysis of plastic waste components. Sustainability 10(11):3979

Liu X, Yan Z, Wang H, Luo Y (2003) In-situ synthesis of NaY zeolite with coal-based kaolin. J Nat Gas Chem 12:63–70

Ratnasari DK, Nahil MA, Williams PT (2017) Catalytic pyrolysis of waste plastics using staged catalysis for production of gasoline range hydrocarbon oils. J Anal Appl Pyrolysis 124:631–637

Rehan M, Miandad R, Barakat MA et al (2017) Effect of zeolite catalysts on pyrolysis liquid oil. Int Biodeterior Biodegrad 119:162–175

Gandidi IM, Susila MD, Rustamaji H (2018) Effect of natural zeolite and kaolin as a catalyst in the isothermal-catalytic cracking of real municipal solid waste (MSW) for bio-oil production. IOP Conf Ser Earth Environ Sci 160:012018

Miandad R, Barakat MA, Rehan M, Aburiazaiza AS, Ismail IMI, Nizami AS (2017) Plastic waste to liquid oil through catalytic pyrolysis using natural and synthetic zeolite catalysts. Waste Manag. https://doi.org/10.1016/j.wasman.2017.08.032

Wongkhorsub C, Chindaprasert N (2013) A comparison of the use of pyrolysis oils in diesel engine. Energy and Power Engineering 5(4B):350–355. https://doi.org/10.4236/epe.2013.54B068

Wiriyaumpaiwong S, Jamradloedluk J (2017) Distillation of pyrolytic oil obtained from fast pyrolysis of plastic wastes. Energy Procedia 138:111–115

Barabás I, Todorut A, Baldean D (2010) Performance and emission characteristics of an CI engine fueled with diesel-biodiesel-bioethanol blends. Fuel 89(12):3827–3832

Sarker M et al (2013) Petroleum production from polystyrene waste. Science and Technology Publishing Inc, New York, pp 1–40. ISBN 978-0-9886890-1-5

Na J-G, Jeong B-H, Seong-Soo Kion SH (2006) Pyrolysis of low density polyethylene using synthetic catalyst produced from fly ash. J Mater Cycles Waste Manag 8:126–132

Technical Information ASTM D975 Diesel Fuel Specification Test (1996) Syntek Global Inc, pp 1–3

Musa U, Mohammed IA, Sadiq MM, Aberuagba F, Olurinde AO, Obamina R (2015) Synthesis and characterization of trimethylolpropane-based biolubricants from castor oil. In: Proceedings of the 45th annual conference of NSCHE, Warri, Nigeria, 5–7 November 2015

Khan MZH, Sultana M, Al-Mamun MR, Hasan MR (2016) Pyrolytic waste plastic oil and its diesel blend: fuel characterization. J Environ Public Health 2016:7869080. https://doi.org/10.1155/2016/7869080

Arunkumar BY, Nataraj CN (2017) Conversion of waste plastic into fuel oil in the presence of bentonite as a catalyst. Int Res J Eng Technol 4(9):114–119

Saptoadiand H, Pratama NN (2015) Utilization of plastics waste oil as partial substitute for kerosene in pressurized cook stoves. Int J Environ Sci Dev 5(6):363–368

Ituen E, Ijioma C (2012) Fuel properties of palm oil biodiesel and its blends with diesel. J Mater Resour 7(1&2):38–48

Acknowledgements

The authors acknowledge the support of Dr. Solomon Gajere Bawa of Petroleum Technology Laboratory, Ahmadu Bello University Zaria, Nigeria, for providing us with the zeolite-Y and assistance in the synthesis of the other catalyst components. The authors also acknowledge the valuable contributions of Dr. Bashir of the Multi-User Laboratory, Ahmadu Bello University, Zaria, Nigeria.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Eze, W.U., Madufor, I.C., Onyeagoro, G.N. et al. The effect of Kankara zeolite-Y-based catalyst on some physical properties of liquid fuel from mixed waste plastics (MWPs) pyrolysis. Polym. Bull. 77, 1399–1415 (2020). https://doi.org/10.1007/s00289-019-02806-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-019-02806-y