Abstract

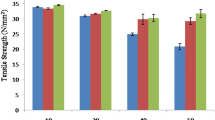

Green coupling agent (GCA) made from waste oil fatty acid was used as an effective coupling agent for polypropylene (PP)/cocoa pod husk (CPH) composites. The results indicated that the incorporation of 0.5 phr of GCA shows a remarkable improvement on tensile strength, elongation at break and tensile modulus of PP/CPH composites. The composites with GCA also exhibited a higher crystallinity and thermal stability as well as water resistivity. The addition of GCA improved the filler dispersion and interfacial adhesion between PP and CPH. Moreover, some properties of PP/CPH composites with GCA are better compared to PP/CPH composites with MAPP or MAA. This outcome implied that GCA could be a potential coupling agent for thermoplastic composite materials.

Similar content being viewed by others

References

Chun KS, Husseinsyah H, Osman H (2013) Modified cocoa pod husk-filled polypropylene composites by using methacrylic acid. BioResour 8:3260–3275. doi:10.15376/biores.8.3.3260-3275

Chun KS, Husseinsyah S, Osman H (2015) Utilization of cocoa pod husk as filler in polypropylene biocomposites: effect of maleated polypropylene. J Thermoplast Compos Mater 28:1507–1521. doi:10.1177/0892705713513291

Chun KS, Husseinsyah S, Osman H (2013) Tensile properties of polypropylene/cocoa pod husk biocomposites: effect of maleated polypropylene. Adv Mater Res 747:645–648. doi:10.4028/www.scientific.net/AMR.747.645

Lucia CM, Renata Dias DMCA, Carmen Lucia DOP (2001) Cacao pod husks (Theobroma cocoa l.): composition and hot-water-soluble. Ind Crop Prod 34:1173–1181. doi:10.1016/j.indcrop.2011.04.004

Chun KS, Husseinsyah S, Yeng CM (2015) Torque rheological properties of polypropylene/cocoa pod husk composites. J Thermoplast Compos Mater. doi:10.1177/0892705715618743

Ljunberg Lennart Y (2007) Materials selection and design for development of sustainable products. Mater Des 28:466–479. doi:10.1016/j.matdes.2005.09.006

Abdul Khalil HPS, Issam AM, Ahmad Shakri MT, Suriani R, Awang AY (2007) Conventional agro-composites from chemically modified fibres. Ind Crop Prod 26:315–323. doi:10.1016/j.indcrop.2007.03.010

Kabir MM, Wang H, Lau KT, Cardona F (2012) Chemical treatments on plant-based natural fibre reinforced polymer composites: an overview. Compos Part B 43:2883–2892. doi:10.1016/j.compositesb.2012.04.053

Bledzki AK, Reihmane S, Gassan J (1998) Thermoplastic reinforced with wood fillers: a literature review. Polym Plast Technol Eng 37:451–468. doi:10.1080/03602559808001373

Fronaco HPJ, Gozalez VAA (2005) A study of the mechanical properties of short natural-fiber reinforced composites. Compos Part B 36:597–608. doi:10.1016/j.compositesb.2005.04.001

Jae GG, Sun YL, Sang JC, Geum HD, Jung HK (2010) Effect of chemical treatment of hybrid fillers on the physical and thermal properties of wood plastic composites. Compos Part A 41:1491–1497. doi:10.1016/j.compositesa.2010.06.011

Chun KS, Husseinsyah S, Osman H (2013) Properties of coconut shell powder-filled polylactic acid ecocomposites: effect of maleic acid. Polym Eng Sci 53:1109–1116. doi:10.1002/pen.23359

Salmah H, Koay SC, Hakimah O (2013) Surface modification of coconut shell powder filled polylactic acid biocomposites. J Thermoplast Compos Mater 26:809–819. doi:10.1177/0892705711429981

Rahman R, Hasan M, Huque M, Islam N (2009) Physico-mechanical properties of melaic acid post treated jute fiber reinforced polypropylene composites. J Thermoplast Compos Mater 22:2945–2955. doi:10.1177/0892705709100664

Xie Y, Hill CAS, Xiao Z, Militz H, Mai C (2010) Silane coupling agents used for natural fiber/polymer composites: a review. Compos Part 41:806–819. doi:10.1016/j.compositesa.2010.03.005

Chun KS, Husseinsyah S, Osman H (2012) Mechanical and thermal properties of coconut shell powder filled polylactic acid biocomposites: effect of the filler content and silane coupling agent. J Polym Res 19:1–8. doi:10.1007/s10965-012-9859-8

Raj RG, Kokta BV, Daneault GG (1990) The influence of coupling agent on mechanical properties of composites containing cellulosic filler. Polym Plast Technol Eng 29:339–353. doi:10.1080/03602559008049849

Salmah H, Ismail H (2008) The effect of filler loading and meleated polypropylene on properties of rubber wood filled polypropylene/natural rubber composites. J Reinf Plast Compos 27:1867–1876. doi:10.1177/0731684407081382

Sombatsompop N, Yotinwattanakumtorn C, Thongpin C. Influence of type and concentration of maleic anhydride grafted polypropylene and impact modifiers on mechanical properties of PP/wood sawdust composites. J Appl Polym Sci 97:475–484. doi:10.1002/app.21765

Danyadi L, Janecska T, Szabo Z, Nagy G, Moczo J, Pukanszky B (2007) Wood flour filled PP composites: compatibilization and adhesion. Compos Sci Technol 67:2838–2846. doi:10.1016/j.compscitech.2007.01.024

Koay SC, Salmah H, Azizi FN (2013) Characterization and properties of recycled polypropylene/coconut shell powder composites: effect of sodium dodecyl sulphate modification. Polym Plast Technol Eng 52:287–294. doi:10.1080/03602559.2012.749282

Chun KS, Husseinsyah S (2012) Polylactic acid/corn cob eco-composites: effect of new organic coupling agent. J Thermoplast Compos Mater 27:1667–1678. doi:10.1177/0892705712475008

Salmah H, Chun KS, Akmal H, Romisuhani A (2014) Effect of filler loading and coconut oil coupling agent on properties of low density polyethylene and palm kernel shell eco-composites. J Vinly Add Technol. doi:10.1002/vnl.21423

Danyadi L, Moczo J, Pukanszky B (2010) Effect of various surface modification of wood flour on the properties of PP/wood composites. Compos Part A 41:199–206. doi:10.1016/j.compositesa.2009.10.008

Raj RG, Kokta BV (1989) Compounding of cellulose fibers with polypropylene: effect of fiber treatment on dispersion in the polymer matrix. J Appl Polym Sci 38:1987–1996. doi:10.1002/app.1989.070381103

Suryadiansyah IH, Azhari B (2007) Waste paper filled polypropylene composites: the comparison effect of ethylene diamine dilaurate as a new compatibilizer with maleic anhydride polypropylene. J Reinf Plast Compos 26:51–67. doi:10.1177/0731684407069953

Rahman WAWA, Lee TS, Rahmat AR, Isa NM, Salleh MSN, Mokhtar M (2010) Comparison of rice husk-filled polyethylene composite and natural wood under weathering effects. J Compos Mater 45:1403–1410. doi:10.1177/0021998310381545

ASTM Standard D638 (2010) Standard test method for tensile properties of plastics. ASTM International, West Conshohocken, PA. doi:10.1520/D0638-10

ASTM Standard D570 (2010) Standard test method for water absorption of plastics. ASTM International, West Conshohocken, PA. doi:10.1520/D0570-98R10E01

Demjen Z, Pukanszky B (1997) Effect of surface coverage of silane treated CaCO3 on the tensile properties of polypropylene composites. Polym Compos 18:741–747. doi:10.1002/pc.10326

Jandas PJ, Mohanty S, Nayak SK, Srivastave H (2011) Effect of surface treatment of banana fiber on mechanical, thermal, and biodegradability properties of PLA/banana fiber biocomposites. Polym Compos 32:1689–1700. doi:10.1002/pc.21165

Lu JZ, Wu Q, Negulescu II (2005) Wood-fiber/high-density-polyethylene composites: coupling agent performance. J Appl Polym Sci 96:93–102. doi:10.1002/app.21410

Pukánszky B (1990) Influence of interface interaction on the ultimate tensile properties of polymer composites. Compos 21:255–262. doi:10.1016/0010-4361(90)90240-W

Danyadi L, Renner K, Moczo J, Pukánszky B (2007) Wood flour filled polypropylene composites: interfacial adhesion and micromechanical deformations. Polym Eng Sci 47:1246–1255. doi:10.1002/pen.20768

Chindaprasirt P, Hiziroglu S, Waisurasingha C, Kasemsiri P (2014) Properties of wood flour/expanded polystyrene waste composites modified with diammonium phosphate flame retardant. Polym Compos 36:604–612. doi:10.1022/pc.22977

Zhao Y, Qiu J, Feng H, Zhang M (2012) The interfacial modification of rice straw fiber reinforced poly(butylene succinate) composites: effect of aminosilane with different alkoxy groups. J Appl Polym Sci 125:3211–3220. doi:10.1002/app.36502

George J, Bhagawan SS, Thomas S (1998) Effect of environment on the properties of low-density polyethylene composites reinforced with pineapple-leaf fiber. Compos Sci Technol 58:1471–1485. doi:10.1016/S0266-3538(97)00161-9

Kushwaha PK, Kumar R (2010) Studies on water absorption of bamboo-polyester composites: effect of silane treatment of mercerized bamboo. Polym Plast Technol Eng 49:45–52

Ayrilmis N, Kaymakci A (2013) Fast growing biomass as reinforcing filler in thermoplastic composites: paulownia elongata wood. Ind Corp Prod 43:457–468. doi:10.1080/03602550903283026

Arbelaiz A, Fernandez B, Ramos JA, Mandragon I (2006) Thermal and crystallization studies of short flax fibre reinforced polypropylene matrix composites: effect of treatments. Thermochim Acta 440:111–121. doi:10.1016/j.tca.2005.10.016

Araujo JR, Waldman WR, De Paoli MA (2008) Thermal properties of high density polyethylene composites with natural fibres: coupling agent effect. Polym Degrad Stab 93:1770–1775. doi:10.1016/j.polymdegradstab.2008.07.021

Amri F, Husseinsyah S, Hussin K (2013) Effect of sodium dodecyl sulfate on mechanical and thermal properties of polypropylene/chitosan composites. J Thermoplast Compos Mater 26:878–892. doi:10.1177/0892705711430430

Acknowledgments

The authors are thankful to Dr. Alias from Cocoa Research and Development Centre (Hilir Perak), Malaysian Cocoa Board for providing the cocoa pod husk waste for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chun, K.S., Husseinsyah, S. & Yeng, C.M. Effect of green coupling agent from waste oil fatty acid on the properties of polypropylene/cocoa pod husk composites. Polym. Bull. 73, 3465–3484 (2016). https://doi.org/10.1007/s00289-016-1682-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-016-1682-7