Abstract

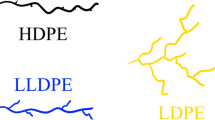

Polyethylenes with bimodal molecular weight distribution were synthesized by using dual catalyst systems. It is found that the molecular weight and its distribution is highly influenced by the molar ratio between the two catalytic centres, and that a synergistic effect exists, being the molecular weight of the products higher than that corresponding to the materials obtained from the isolated catalysts. What it is interesting is that the molecular weight distribution shape, the microstructure and the final polymer properties could be regulated by the selection of this ratio. Results from this study show that materials with a broad range of microstructures, crystallinities and mechanical properties are obtained. The correlations found show that although a double population of macromolecular species exists, both are able to co-crystallize to form a unique crystalline structure from dilute solution. Rheological testing point towards a pronounced shear thinning behaviour, very high relaxation times, and thermorheological complexity, suggesting the incorporation of long chain branching during the polymerisation process. In addition, simple additive models applied to the linear viscoelastic properties of the polymers, by using the rheological response of the pure components, are unable to explain the experimental results obtained, suggesting a tandem effect rather than a dual action between the two active centres.

Similar content being viewed by others

References

Mu~noz-Escalona A, Lafuente P, Vega JF, Santamaría A (1999) Polym Eng Sci 39:2292

DesLauriers PJ, McDaniel MP, Rohlfing DC, Krishnaswamy RK, Secora SJ, Benham EA, Maeger PL, Wolfe AR, Sukhadia AM, Beaulieu BB (2005) Polym Eng Sci 45:1203

Aguilar M, Expósito MT, Vega JF, Mu~noz-Escalona A, Martínez-Salazar J (2004) Macromolecules 37:681

Aguilar M, Martín S, Vega JF, Mu~noz-Escalona A, Martínez-Salazar J (2005) J Polym Sci Polym Phys 43:963

Barrera MA, Vega JF, Aguilar M, Martínez-Salazar J (2006) J Mat Process Technol 174:171

Peón J, Domínguez C, Vega JF, Aroca M, Martínez-Salazar J (2003) J Mat Sci 38:4757

Commereuc D, Hugues F, Le Quan N, Taouli A (1988) US Patent No 4721762

Pettijohn TM, Reagen WK, Martin SJ (1995) US Patent No 5393719

Michiels W, Mu~noz-Escalona A (1996) European Patent No 0719797

Reagen WK, Pettijohn TM, Freeman JW, Benham EA (1998) US Patent No 5786431

Ahlers A, Kaminsky W (1988) Makromol Chem Rapid Commun 9:457

Heiland K, Kaminsky W (1992) Makromol Chem 193:601

Han TK, Choi HK, Jeung DW, Ko YS, Woo SI (1995) Macromol Chem Phys 196:2637

D’Agnillo L, Soares JBP, Penlidis A (1998) J Polym Sci Polym Chem 36:831

Kim JD, Soares JBP, Rempel GL (1999) J Polym Sci Polym Chem 37:331

Liu J, Rytter E (2001) Macromol Rapid Commun 22:952

Quijada R, Rojas R, Bazán G, Komon ZJA, Mauler RS, Galland GB (2001) Macromolecules 34:241

Dekmezian AH, Soares JBP, Jiang P, Garcia-Franco CA, Weng W, Fruitwala H, Sun T, Sarzotti DM (2002) Macromolecules 35:9586

Bruaseth I, Rytter E (2003) Macromolecules 36:3026

de Wet-Roos D, Dixon JT (2004) Macromolecules 37:9314

Lu ZX, Zhang Z, Li Y, Wu C, Hu Y (2006) J Appl Polym Sci 99:2898

Expósito MT, Vega JF, Martínez-Salazar J (2007) J Appl Polym Sci in press

Quinn FA Jr, Mandelkern L (1958) J Am Chem Soc 80:3178

Mavridis H, Shroff R (1992) Polym Eng Sci 132:1778

Ramos J, Cruz V, Mu~noz-Escalona A, Martínez-Salazar J (2002) Polymer 43:363

Sarzotti DM, Soares JBP, Penlidis A (2002) J Polym Sci Polym Phys 40:2595

Sarzotti DM, Soares JBP, Simon LC, Britto LJD (2004) Polymer 45:4787

Expósito MT (2006) PhD Thesis, Universidad Complutense de Madrid

Martínez-Salazar J, Sánchez Cuesta M, Plans J (1991) Polymer 32:984

Vega JF, Aguilar M, Martínez-Salazar J (2003) J Rheol 47:1505

Wood-Adams P, Costeux S (2001) Macromolecules 34:6281

Lee HS, Denn MM (2000) Polym Eng Sci 40:1132

des Cloizeaux J (1988) Europhys Lett 5:437

Tsenoglou C (1991) Macromolecules 24:1762

Groves DJ, McLeish TCB, Choham RK, Coates PD (1996) Rheol Acta 35:481

Maier D, Eckstein A, Friedrich C, Honerkamp J (1998) J Rheol 42:1153

Thimm W, Friedrich C, Marth M, Honerkamp J (1999) J Rheol 43:663

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vega, J.F., Otegui, J., Expósito, M.T. et al. Structure and Physical Properties of Polyethylenes obtained from Dual Catalysis Process . Polym. Bull. 60, 331–342 (2008). https://doi.org/10.1007/s00289-007-0871-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-007-0871-9