Abstract

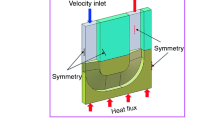

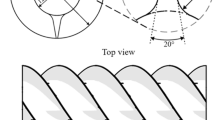

Temperature oscillation usually occurs in the LHP operation, which would impede the temperature controlling ability of LHPs. Therefore, in this paper, the characteristics of temperature oscillation for the LHP enhanced by pressure head of evaporation was fully discussed, in which relationship between the temperature oscillation and flow pattern in the condenser was also clarified by using the PU and copper condenser. The experiment results showed different types of temperature oscillation were related to different flow patterns in the condenser. Type one of temperature oscillation (the frequency and amplitude were large than 30 s and 5 °C, respectively) was corresponding to the slug flow in condenser; Type two of temperature oscillation was corresponding to the semi-annular flow in condenser, in which the LHP temperatures were almost same and the frequency and amplitude ranged from 5 s to 30 s and 1 °C to 5 °C, respectively. Type three of temperature oscillation was corresponding to the plug flow and it was favorite to the LHP operation, in which the frequency and amplitude of evaporator inlet were 450 s/140 s and 3 °C/3 °C at 60 W/160 W, respectively. Moreover, the temperature oscillation orderly varied from Type three to Type one and Type two with the increase of heat load, corresponding to plug flow, slug flow and semi-annular flow in condenser.

Similar content being viewed by others

Abbreviations

- A:

-

Area of the heater, m2

- T:

-

Temperature, oC

- R:

-

Thermal resistance, oC/W

- Q:

-

Heat load, W

- P:

-

Pressure, Pa

- \(\Delta\) P:

-

Pressure difference, Pa

- \({X}_{i}\) :

-

Variable

- \(\updelta {X}_{i}\) :

-

Uncertainty in one variable

- \({\delta Y}\) :

-

Overall uncertainty

- LHP:

-

Loop heat pipe

- e:

-

Evaporator

- c:

-

Condenser

- n, n-1:

-

Time series at n and n-1

- w:

-

Wick

- contr:

-

Local resistance

- p:

-

Pipe

- g:

-

Gravity

- cap:

-

Capillary force

- dr:

-

Pressure head of evaporation

- sys :

-

Total

References

Hamdan M, Elnajjar H (2009) Thermodynamic analytical model of a loop heat pipe. Heat Mass Transfer 46:167–173

Singh R, Akbarzadeh A, Dixon C, Mochizuki M (2009) Theoretical modelling of miniature loop heat pipe. Heat Mass Transfer 46:209–224

Zhang H, Jiang C, Zhang ZK, Liu ZC, Luo XB, Liu W (2020) A study on thermal performance of a pump-assisted loop heat pipe with ammonia as working fluid. Appl Therm Eng 175:115342

Li J, Zhou Y, Cheng L (2010) Experimental study on capillary pumping performance of porous wicks for loop heat pipe. Therm Fluid Sci 34:1403–1408

Xie YQ, Li XY, Han LZ, Zhu JQ, Gao H, Wen DS (2020) Experimental study on operating characteristics of a dual compensation chamber loop heat pipe in periodic acceleration fields. Appl Therm Eng 176:115419

Gai DX, Liu ZX, Liu W, Yang JG (2009) Operational characteristics of miniature loop heat pipewith flat evaporator. Heat Mass Transfer 46:267–275

Zhou L, Qu ZG, Chen G, Huang JY, Miao JY (2019) One-dimensional numerical study for loop heat pipe with two-phase heat leak model. Int J Therm Sci 137:467–481

Ku J, Jose I (2003) Low frequency high amplitude temperature oscillations in loop heat pipe operation. SAE Technical Paper 2003:2003–01–2386

Wang DD, Liu ZC, Shen J, Jiang C, Chen BB, Yang JG, Tu ZK, Liu W (2014) Experimental study of the loop heat pipe with a flat disk-shaped evaporator. Exp Therm Fluid Sci 57:157–164

Li J, Lv LC, Zhou GH, Li XP (2019) Mechanism of a microscale flat plate heat pipe with extremely high nominal thermal conductivity for cooling high-end smartphone chips. Energy Convers Manage 201:112202

Chernysheva M, Maydanik Y (2019) Simulation of heat and mass transfer in a cylindrical evaporator of a loop heat pipe. Int J Heat Mass Tran 131:442–449

Xiao B, Deng WZ, Ma ZY, He S, He L, Li X, Yuan F, Liu W, Liu ZC (2020) Experimental investigation of loop heat pipe with a large squared evaporator for multi-heat sources cooling. Renew Energy 147:239–248

Zhang X, Huo J, Wang S (2012) Experimental investigation on temperature oscillation in a miniature loop heat pipe with flat evaporator. Exp Therm Fluid Sci 37:29–36

Hong SH, Zhang XQ, Wang SF, Zhang ZG (2015) Experimental study on heat transfer capability of an innovative gravity assisted ultra-thin looped heat pipe. Int J Therm Sci 95:106–114

Liu ZC, Gai DX, Li H, Liu W, Yang JG, Liu MM (2011) Investigation of impact of different working fluids on the operational characteristics of miniature LHP with flat evaporator. Appl Therm Eng 31:3387–3392

Santos P, Bazzo E, Oliveira A (2012) Thermal performance and capillary limit of a ceramic wick applied to LHP and CPL. Appl Therm Eng 41:92–103

Xu JY, Zhang L, Xu H (2012) Performance of LHPs with a novel design evaporator. Int J Heat Mass Tran 55:7005–7014

Adachi T, Fujita K, Nagai H (2019) Numerical study of temperature oscillation in loop heat pipe. Appl Therm Eng 163:114281

J Ku 2001 Ottenstein L, Kobel M, Rogers P, Kaya T (2001) Temperature oscillation in loop heat pipe operation AIP Conf Proc 2001 https://doi.org/10.1063/1.1357932

Ku J (2003) High frequency low amplitude temperature oscillations in loop heat pipe operation. SAE Technical Paper 2003:2003–01–2387

Zhu K, Li X, Li H, Yang Z, Wang Y (2019) Experimental investigation on the effect of heat sink temperature on operational characteristics of a new-type loop heat pipe. Energy Proc 158:2423–2429

Yang Y, Zhu K, Wang Y, Wei J, Zheng M, Cui Z (2016) Experimental investigation and visual observation of a vapor-liquid separated flat loop heat pipe evaporator. Appl Therm Eng 101:71–78

Zhu K, Li X, Li H, Chen X, Wang Y (2018) Experimental and theoretical study of a novel loop heat pipe. Appl Therm Eng 130:354–362

Li X, Zhu K, Li H, Chen X, Wang Y (2019) Performance comparison regarding loop heat pipes with different evaporator structures. Int J Therm Sci 136:86–95

Cimbala J, Brenizer JS, Chuang AP, Hanna S, Conroy CT, Elganayni AA, Riley DR (2004) Study of a loop heat pipe using neutron radiography. Appl Radiat Isotopes 61(4):701–705

Bartuli E, Vershinin S, Maydanik Y (2013) Visual and instrumental investigations of a copper-water loop heat pipe. Int J Heat Mass Tran 61:35–40

Zhou GH, Li J (2018) Two-phase flow characteristics of a high performance loop heat pipe with flat evaporator under gravity. Int J Heat Mass Tran 117:1063–1074

Collier JG, Thome JR (1994) Convective boiling and condensation, 3rd edn. Oxford University Press, Oxford

Charnay R, Revellin R, Bonjour J (2013) Flow pattern characterization for R-245fa in minichannels: Optical measurement technique and experimental results. Int J Multiphas Flow 57:169–181

Deng D, Liang D, Tang Y, Peng J, Han X, Pan M (2013) Evaluation of capillary performance of sintered porous wicks for loop heat pipe. Exp Therm Fluid Sci 50:1–9

Li H, Liu ZC, Chen BB, Liu W, Li C, Yang J (2012) Development of biporous wicks for flat-plate loop heat pipe. Exp Therm Fluid Sci 37:91–97

Zhou G, Li J, Jia Z (2019) Power-saving exploration for high-end ultra-slim laptop computers with miniature loop heat pipe cooling module. Appl Energy 239:859–875

Liu J, Zhang Y, Feng C, Liu L, Luan T (2019) Study of copper chemical-plating modified polyacrylonitrile-based carbon fiber wick applied to compact loop heat pipe. Exp Therm Fluid Sci 100:104–113

Moffat R (1998) Describing the uncertainties in experimental results. Exp Therm Fluid Sci 1(1):3–17

Acknowledgements

This work is supported by Tianjin Natural Science Foundation (No. 18JCZDJC97100) and National Natural Science Foundation of China (No. 51376137). The financial supports are sincerely appreciated.

Author information

Authors and Affiliations

Contributions

Xueqiang Li: Methodology, Data curation, Formal analysis, Writing—original draft, Writing—review & editing. Zhongyao Zhang: Experiment, Data curation, Investigation. Yabo Wang: Methodology, Conceptualization, Supervision, Writing—review & editing. Kai Zhu: Conceptualization, Methodology, Funding acquisition, Project administration. Shengchun Liu: Supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, X., Zhang, Z., Wang, Y. et al. Characteristic of temperature oscillation during the operation of loop heat pipe enhanced by pressure head of evaporation. Heat Mass Transfer 58, 1145–1155 (2022). https://doi.org/10.1007/s00231-021-03149-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-021-03149-z