Abstract

In this study, the radiative properties of the surfaces of an electric oven were investigated. Using experimental data related to an oven-like enclosure, a novel combination of surface properties was developed. Three different surface emissivity combinations were analysed experimentally: low-emissivity, high emissivity (black-coated), and hybrid emissivity. The term “hybrid emissivity design” here corresponds to an enclosure with some high emissive and some low-emissive surfaces. The experiments were carried out according to the EN 50304 standard. When a brick (load) was placed in the enclosure, the view factors between its surfaces were calculated with the Monte Carlo method. These and the measured surface temperatures were then used to calculate the radiative heat fluxes on the surfaces of the load. The three different models were compared with respect to energy consumption and baking time. The hybrid model performed best, with the highest radiative heat transfer between the surfaces of the enclosure and the load and minimum heat loss from the cavity. Thus, it was the most efficient model with the lowest energy consumption and the shortest baking time. The recent European Union regulation regarding the energy labelling of domestic ovens was used.

Similar content being viewed by others

Change history

24 June 2017

An erratum to this article has been published.

Abbreviations

- CENELEC:

-

European Committee for Electrotechnical Standardization

- EC:

-

energy consumption required to heat a standardised load in a cavity

- EEI:

-

energy efficiency index

- EIA:

-

U.S. Energy Information Administration

- EU:

-

European Union

- PID:

-

proportional–integral–derivative

- RTD:

-

resistive temperature device

- SEC:

-

standard energy consumption (electricity) required to heat a standardised load in a cavity

- US:

-

United States

- N:

-

total number of packets

- S:

-

number of absorbed packets

- R:

-

random number

- N:

-

packet index

- A:

-

area (m2)

- T:

-

absolute temperature (K)

- q:

-

net radiative transfer from surface (W)

- J:

-

radiosity (W/m2)

- E:

-

emissive power (W/m2)

- F:

-

view factor

- V:

-

volume (L)

- Ra:

-

Rayleigh number

- Nu:

-

Nusselt number

- g:

-

gravitational acceleration (m/s2)

- L:

-

characteristic length (m)

- h:

-

heat transfer coefficient (W/m2 K)

- k:

-

thermal conductivity (W/m K)

- ε:

-

emissivity

- σ:

-

Stefan-Boltzmann constant (W/m2 K4)

- Φ:

-

circumferential angle (°)

- Θ:

-

cone angle (°)

- β:

-

expansion coefficient (1/K)

- α:

-

thermal diffusivity (m2/s)

- ν:

-

kinematic viscosity (m2/s)

- s:

-

surface

- f:

-

film

- ∞:

-

free stream

References

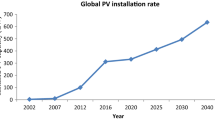

EIA (2013) International Energy Outlook www.eia.gov/forecasts/ieo/pdf/0484(2013).pdf

IEA (2008) Worldwide Trends in Energy Use and Efficiency Worldwide Trends in Energy Use and Efficiency http://www.iea.org/publications/freepublications/publication/Indicators_2008.pdf

EU (2014) http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2014:029:0001:0032:EN:PDF

Shaughnessy BM, Newborough M (2000) Energy performance of a low-emissivity electrically heated oven. Appl Therm Eng. doi:10.1016/S1359-4311(99)00072-1

Bansal P, Vineyard E, Abdelaziz O (2011) Advances in household appliances – a review. Appl Therm Eng. doi:10.1016/j.applthermaleng.2011.07.023

Mistry H, Ganapathisubbu S, Dey S, Bishnoi P, Castillo JL (2006) Modeling of transient natural convection heat transfer in electric ovens. Appl Therm Eng. doi:10.1016/j.applthermaleng.2006.02.007

Mistry H, Ganapathisubbu S, Dey S, Bishnoi P, Castillo JL (2011) A methodology to model flow-thermals inside a domestic gas oven. Appl Therm Eng. doi:10.1016/j.applthermaleng.2010.08.022

Boulet M, Marcos B, Dostie M, Moresoli C (2010) CFD modeling of heat transfer and flow field in a bakery pilot oven. J Food Eng. doi:10.1016/j.jfoodeng.2009.10.034

Chhanwal N, Anishaparvin A, Indrani D, Raghavarao KSMS, Anandharamakrishnan C (2010) Computational fluid dynamics (CFD) modeling of an electrical heating oven for bread-baking process. J Food Eng. doi:10.1016/j.jfoodeng.2010.04.030

Khatir Z, Paton J, Thompson H, Kapur N, Toropov V, Lawes M, Kirk D (2012) Computational fluid dynamics (CFD) investigation of air flow and temperature distribution in a small scale bread-baking oven. Appl Energy. doi:10.1016/j.apenergy.2011.02.002

Ploteau JP, Nicolas V, Glouanne P (2012) Numerical and experimental characterization of a batch bread baking oven. Appl Therm Eng. doi:10.1016/j.applthermaleng.2012.04.060

Scarisbrick C, Newborough M, Probert SD (1991) Improving the thermal performances of domestic electric ovens. Appl Energy. doi:10.1016/0306-2619(91)90001-E

Bignardi C, Cavazza A, Rinaldi M, Corradini C, Massini R (2013) Evaluation of thermal treatment markers in wheat flour-derived products cooked in conventional and in low-emissivity ovens. Food Chem. doi:10.1016/j.foodchem.2012.12.006

European Committee for Electrotechnical Standardization (CENELEC) (2001) Electric ovens for household use – methods for measuring energy consumption, EN 50304

Siegel R, Howell JR (2002) Thermal radiation heat transfer, Taylor&Francis, London

Incropera F, Dewitt D, Bergman TL, Lavine AS (2006) Fundamentals of heat and mass transfer. Wiley, New York

Acknowledgements

The authors would like to thank The Scientific and Technological Research Council of Turkey (TUBITAK) (grant no:111 M048) and ARCELIK A.S R&D Department for their financial support. The authors are also grateful to the reviewers for their valuable feedbacks.

Author information

Authors and Affiliations

Corresponding author

Additional information

The original version of this article was revised: The names of the authors were incorrectly presented. It should be Ozgur Isik and Seyhan Uygur Onbasioglu.

An erratum to this article is available at https://doi.org/10.1007/s00231-017-2085-5.

Rights and permissions

About this article

Cite this article

Isik, O., Onbasioglu, S.U. Design of a hybrid emissivity domestic electric oven. Heat Mass Transfer 53, 3189–3198 (2017). https://doi.org/10.1007/s00231-017-2071-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-017-2071-y