Abstract

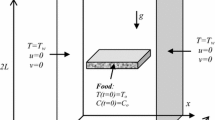

This study presents a two dimensional analysis of coupled heat and mass transfer during the process of pasta drying. Velocity and temperature distributions of air flowing around the pasta are predicted in steady state condition. Using these profiles and the similarity between heat and mass boundary layers, local convective heat and mass transfer coefficients were determined on different points of pasta surface. By employing these values, the solution of coupled heat and mass transfer equations within the pasta object in unsteady state condition was obtained. Furthermore the effects of operating conditions such as velocity, temperature and relative humidity of air flow on drying rate of pasta were studied. Sensitivity analysis results show that the effects of air temperature and relative humidity on the rate of drying are more important than the effect of air velocity. Finally, the results obtained from this analysis were compared with the experimental data reported in the literatures and a good agreement was observed while, no adjustable parameter is used in the presented model.

Similar content being viewed by others

Abbreviations

- a w :

-

Water activity (−)

- c :

-

Concentration (kg/m3)

- C p :

-

Heat capacity (J/kg K)

- c s,air :

-

Water concentration in gaseous phase at pasta/air interface (kg/m3)

- d :

-

Diameter (m)

- D eff :

-

Effective moisture diffusion coefficient (m2/s)

- D w−air :

-

Diffusion coefficient of water in air (m2/s)

- h :

-

Heat transfer coefficient (W/m2 K)

- k :

-

Thermal conductivity (W/m K)

- k c :

-

Mass transfer coefficient (m/s)

- Le:

-

Lewis number (−)

- M w :

-

Water molar weight (kg/mol)

- n :

-

Normal vector to surface

- N s :

-

Water mass flux (kg/m2 s)

- p 0 :

-

Vapor pressure (Pa)

- P :

-

Total pressure (Pa)

- R g :

-

Universal gas constant (J/mol K)

- RH :

-

Relative humidity of air (−)

- s :

-

Surface coordinate

- t :

-

Time (s)

- T :

-

Pasta temperature (K)

- T air :

-

Air temperature (K)

- T f :

-

Film temperature (°C)

- u :

-

x-Component of velocity vector (m/s)

- u :

-

Velocity vector (m/s)

- U :

-

Moisture content in pasta on wet basis (w/w)

- v :

-

y-Component of velocity vector (m/s)

- X :

-

Moisture content in pasta on dry basis (−)

- y :

-

Molar fraction in air (−)

- y s , air :

-

Mole fraction in gaseous phase at pasta/air interface (−)

- α :

-

Thermal diffusivity (m2/s)

- δ :

-

Pasta thickness (m)

- λ :

-

Water latent heat of vaporization (J/kg)

- μ :

-

Viscosity (kg/m s)

- θ :

-

Dimensionless temperature \(\frac{{T - T_{0} }}{{T_{\infty } - T_{0} }}\)

- ρ :

-

Density (kg/m3)

- 0:

-

Initial condition

- ∞:

-

Bulk condition

- air :

-

Air

- s :

-

Pasta surface

- w :

-

Water

References

Andrieu J, Stamatopoulos AA (1986) Durum wheat pasta drying kinetics. Lebensm Wiss Technol 19:448–456

Migliori M, Gabriele D, de Cindio B, Pollini CM (2005) Modelling of high quality pasta drying: mathematical model and validation. J Food Eng 69:387–397

Migliori M, Gabriele D, de Cindio B, Pollini CM (2005) Modelling of high quality pasta drying: quality indices and industrial application. J Food Eng 71:242–251

Bird RB, Stewart WE, Lightfoot EN (2002) Transport phenomena, 2nd edn. Wiley, New York

De Temmerman J, Verboven P, Nicolai B, Ramon H (2007) Modelling of transient moisture concentration of semolina pasta during air drying. J Food Eng 80:892–903

Veladat R, Ashtiani FZ, Rahmani M, Miri T (2012) Review of numerical modeling of pasta drying, a closer look into model parameters. Asia Pac J Chem Eng 7:159–170

Saravacos GD, Maroulis ZB (2001) Transport properties of foods. Marcel Dekker, New York

De Temmerman J, Verboven P, Delcour JA, Nicolaï B, Ramon H (2008) Drying model for cylindrical pasta shapes using desorption isotherms. J Food Eng 86:414–421

Himmelblau DM, Riggs JB (2004) Basic principles and calculations in chemical engineering, 7th edn. Prentice Hall PTR, Upper Saddle River

Perry RH, Green DW, Maloney JO (2001) Perry’s chemical engineers’ handbook, 7th edn. McGraw-Hill, New York

Islam MR, Ho JC, Mujumdar AS (2003) Simulation of liquid diffusion-controlled drying of shrinking thin slabs subjected to multiple heat sources. Dry Technol 21:413–438

Incropera FP, DeWitt DP (2002) Fundamentals of heat and mass transfer, 5th edn. Wiley, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Veladat, R., Ashtiani, F.Z. & Rahmani, M. A rigorous analysis of simultaneous heat and mass transfer in the pasta drying process. Heat Mass Transfer 49, 1481–1488 (2013). https://doi.org/10.1007/s00231-013-1189-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-013-1189-9