Abstract

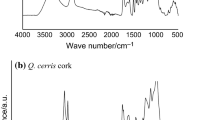

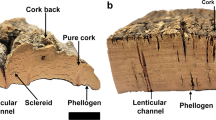

Cork and cork components (suberin, lignin, holocellulose, sclereids, and lenticels) were obtained by manual and chemical methods. Dynamic thermogravimetric analysis was used to investigate the thermal behavior of cork and its components. Thermal decomposition of cork was different from that of natural fibers. Characteristic temperatures of thermal decomposition for cork and impurities (sclereids and lenticels) were related to their chemical components. Cork lignin has the decomposition characteristics of G-type (guaiacyl units) lignin, typical of softwood with high residual solids. The pyrolysis characteristics of Quercus variabilis Blume (Q. variabilis) suberin was close to Quercus cerris L. (Q. cerris) suberin. The decomposition temperature range of cork, lignin, or suberin was wider than that of sclereids, lenticels, or holocellulose. Activation energy of cork was lower than that of natural fibers. The activation energy of cork and the extracted suberin was slightly increased when the conversion rate α was greater than 0.35. Activation energies of sclereids and lenticels were close to each other due to similar composition and proportion in them.

Similar content being viewed by others

References

Antal MJ, Varhegyi G (1995) Cellulose pyrolysis kinetic—the current state knowledge. Ind Eng Chem Res 34:703–717

Aroso IV, Duarte ARC, Pires RR, Mano JF, Reis RL (2015) Cork processing with supercritical carbon dioxide: impregnation and sorption studies. J Supercrit Fluids 104:251–258

Arrhenius S (1889) On the reaction rate of the inversion of non-refined sugar upon souring. Z Phys Chem 4:226–248

Chevreul M (1807) De l’action de l’acide nitrique sur le liège (The effect of nitric acid on cork). Ann Chim 92:323–333 (in French)

Cordeiro N, Belgacem NM, Gandini A, Neto CP (1998) Cork suberin as a new source of chemicals: 2. Crystallinity, thermal and rheological properties. Bioresour Technol 63:153–158

Ferreira R, Garcia H, Sousa AF, Freire CSR, Silvestre AJD, Rebelo LPN, Pereira CS (2013) Isolation of suberin from birch outer bark and cork using ionic liquids: a new source of macromonomers. Ind Crop Prod 44:520–527

Ferreira J, Miranda I, Şen U, Pereira H (2016) Chemical and cellular features of virgin and reproduction cork from Quercus variabilis. Ind Crop Prod 94:638–648

Gangil S (2015) Superiority of intrinsic biopolymeric constituents in briquettes of lignocellulosic crop residues over wood: a TG-diagnosis. Renew Energy 76:478–483

Graça J, Pereira H (2000) Methanolysis of bark suberins: analysis of glycerol and acid monomers. Phytochem Anal 11:45–51

Grønli MG, Várhegyi G, Blasi CD (2002) Thermogravimetric analysis and devolatilization kinetics of wood. Ind Eng Chem Res 41:4201–4208

Hu J, Shen D, Xiao R, Wu S, Zhang H (2012) Free-Radical analysis on thermochemical transformation of lignin to phenolic compounds. Energy Fuels 27:1–12

Lagorce-Tachon A, Karbowiak T, Champion D, Gougeon RD, Bellat JP (2015) Mechanical properties of cork: effect of hydration. Mater Design 82:148–154

Lee MY, Lee TS, Park WH (2001) Effect of side chains on the thermal degradation of poly (3-hydroxyalkanoates). Macromol Chem Phys 202:1257–1261

Liu Z (1991) An introduction to thermal analysis, 1st edn. Chemical Industry Press, Beijing

Liu T, Li B (2012) Kinetic studies on the pyrolysis of a water-soluble chitosan. J Huazhong Norm Univ 46:65–70

Liu Q, Wang S, Zheng Y, Luo Z, Cen K (2008) Mechanism study of wood lignin pyrolysis by using TG–FTIR analysis. J Anal Appl Pyrolysis 82:170–177

Pereira H (1992) The thermochemical degradation of cork. Wood Sci Technol 26:259–269

Pereira H (2007) Cork: biology, production and uses. Elsevier Science, Amsterdam

Rosa ME, Fortes MA (1987) Temperature-induced alteration of the structure and mechanical properties of cork. Mater Sci Eng 100:69–78

Şen A, Miranda I, Santos S, Graça J, Pereira H (2010) The chemical composition of cork and phloem in the rhytidome of Quercus cerris bark. Ind Crops Prod 31:417–422

Şen A, Marques AV, Gominho J, Pereira H (2012) Study of thermochemical treatments of cork in the 150–400 °C range using colour analysis and FTIR spectroscopy. Ind Crops Prod 38:132–138

Şen A, Bulcke JV, Defoirdt N, Acker JV, Pereira H (2014) Thermal behaviour of cork and cork components. Thermochim Acta 582:94–100

Shen D, Zhang L, Xue J, Guan S, Qian L, Xiao R (2015) Thermal degradation of xylan-based hemicellulose under oxidative atmosphere. Carbohydr Polym 12:363–371

Silva SP, Sabino MA, Fernandes EM, Correlo VN, Boesel LF, Reis RL (2005) Cork: properties, capabilities and applications. Int Mater Rev 50:345–365

Sousa AF, Gandini A, Caetano A, Maria TM, Freire CS, Neto CP, Silvestre AJ (2016) Unravelling the distinct crystallinity and thermal properties of suberin compounds from Quercus suber and Betula pendula outer barks. Int J Biol Macromol 93:686–694

TAPPI (1975) Holocellulose in wood. Standard Test Method 9 wd-75. Technical association of the pulp and paper industry, Atlanta, GA, USA

TAPPI (2011) Acid-insoluble lignin in wood and pulp. Standard Test Method 222 om-11. Technical association of the pulp and paper industry, Atlanta, GA, USA

Tian L, Shen B, Xu H, Li F, Wang Y, Singh S (2016) Thermal behavior of waste tea pyrolysis by TG-FTIR analysis. Energy 103:533–542

Trockenbrodt M (1995) Calcium oxalate crystals in the bark of Quercus robur, Ulmus glabra, Populus tremula and Betula pendula. Ann Bot 75:281–284

Tsujiyama S, Miyamori A (2000) Assignment of DSC thermograms of wood and its components. Thermochim Acta 351:177–181

Vyazovkin S (2000) Kinetic concepts of thermally stimulated reactions in solids: a view from a historical perspective. Int Rev Phys Chem 19:45–60

Wang W (2008) Study on thermogravimetric analysis and pyrolysis kinetics of cellulose. Chongqing University, Chongqing

Wang S, Lin H, Ru B, Sun W, Wang Y, Luo Z (2014) Comparison of the pyrolysis behavior of pyrolytic lignin and milled wood lignin by using TG–FTIR analysis. J Anal Appl Pyrolysis 108:78–85

Yang H, Yan R, Chen H, Dong HL, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Yao F, Wu Q, Lei Y, Guo W, Xu Y (2008) Thermal decomposition kinetics of natural fibers: activation energy with dynamic thermogravimetric analysis. Polym Degrad Stab 93:90–98

Yu H, Liu F, Ke M, Zhang X (2015) Thermogravimetric analysis and kinetic study of bamboo waste treated by Echinodontium taxodii using a modified three-parallel-reactions model. Bioresour Technol 185:324–330

Zhao J (2012) Research in expansion impurities removing technology and mechanisms of Quercus variabilis cork. North west A&F University, Yanling

Zhao J, Feng D, Lei Y, Zhang W, Zhang Y (2013) Cell structure and chemical components of sclereids and lenticels from Quercus variabilis cork. J Northwest Sci Tech Univ Agric For 41:119–124

Zhao J, Wang X, Hu J, Liu Q, Shen D, Xiao R (2014) Thermal degradation of softwood lignin and hardwood lignin by TG-FTIR and Py-GC/MS. Polym Degrad Stab 108:133–138

Zhao J, Song X, Feng D, Lei Y, Zhang Y (2015) Expansion and impurity removal technology for Quercus variabilis cork. J Northwest Sci Tech Univ Agric For 43:87–92

Zhao C, Jiang E, Chen A (2016) Volatile production from pyrolysis of cellulose, hemicellulose and lignin. J Energy Inst 13:1–12

Zou H, Hu K, Gui L, Cheng L, Lu H (2011) Research on optimal characterization method of CaC2O4·H2O by thermogravimetry-differential thermal analyzer. J Guangxi Acad Sci 27:17–21

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 31470583). The authors also acknowledge the Start-up Fund of Northwest A&F University (No. 2452015346).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shangguan, W., Chen, Z., Zhao, J. et al. Thermogravimetric analysis of cork and cork components from Quercus variabilis . Wood Sci Technol 52, 181–192 (2018). https://doi.org/10.1007/s00226-017-0959-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-017-0959-9