Abstract

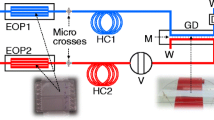

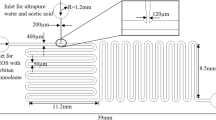

A high-pressure electro-osmotic micro-pump fabricated by a sol–gel process is reported as a fluid-driving unit in a flow-injection analysis (FIA) system. The micro FIA system consists of a monolithic micro-pump on a glass slide (2.5×7.5 cm), a micro-injector, and a micro-sensor (2.5×1.5 cm). The monolithic silica matrix has a continuous skeleton morphology with micrometer-sized through-pores. The micrometer-size pores with a large negative surface charge density build up a large pressure under a DC electric field to drive fluid through the downstream units. A novel Nafion joint for the downstream cathode eliminates flow into the electrode reservoir and further enhances pressure build-up. The measured pump-pressure curve indicated a maximum pressure of 0.4 MPa at flow rate of 0.4 μL min−1 at 6 kV. Despite the large voltage, the small current transmission area through the monolith produced a negligible current (less than 100 μA) that did not generate bubbles or ion contaminants. The flow rate can be precisely controlled in the range 200 nL to 2.5 μL min−1 by varying the voltage from 1 to 6 kV. The high pump pressure and the large current-free DC field also enabled the pump to act as an electro-spray interface with a downstream analytical instrument.

Similar content being viewed by others

References

Chen CH, Santiago JG (2002) J Microelectromech Syst 11:672–683

Zeng S, Chen CH, Mikkelsen JC, Santiago JG (2001) Sens Actuators B 79:107–114

Morf WE, Guenat OT, Rooij NF (2001) Sens Actuators B 72:266–272

Darabi J, Rada M, Ohadi MM, Lawler J (2002) J Microelectromech Syst 11:684–690

Lemoff AV, Lee AP (2000) Sens Actuators B 63:178–185

Laser DJ, Santiago JG (2004) J Micromech Microeng 14:R35–R64

Chen L, Ma J, Guan Y (2003) Microchem J 75:15–21

Liu S, Dasgupta PK (1992) Anal Chim Acta 268:1–6

Lazar IM, Karger BL (2002) Anal Chem 74(24):6259–6268

Lazar IM, Ramsey RS, Jacobson SC, Foote RS, Ramsey JM (2000) J Chromatogr A 892:195–201

Lastochkin D, Zhou R, Wang P, Ben Y, Chang H–C (2004) J Appl Phys 96:1730–1733

Minerick AR, Ostafin AE, Chang H-C (2002) Electrophoresis 23:2165

Mutlu S, Yu C, Selvaganapathy P, Svec F, Mastrangelo CH, Frechet JMJ (2002) In: Proceedings of the IEEE MEMS 2002 Conference, Las Vegas, USA, Jan 20–24, pp 19–24

Razunguzwa TT, Timperman AT (2004) Anal Chem 76:1336–1341

Tripp JA, Svec F, Frechet JMJ, Zeng SL, Mikkelsen JC, Santiago JG (2004) Sens Actuators B 99:66–73

Nakanishi KJ (1997) Porous Mater 4:67–112

Tanaka N, Kobayashi H, Nakanishi K, Minakuchi H, Ishizuka N (2001) Anal Chem 73(15):420A–429A

Chen Z, Hobo T (2001) Anal Chem 73:3348–3357

Chen Z, Hobo T (2001) Electrophoresis 22:3339–3346

Chen Z, Ozawa H, Uchiyama K, Hobo T (2003) Electrophoresis 24:2550–2558

Chen Z, Nishiyama T, Uchiyama K, Hobo T (2004) Anal Chim Acta 501:17–23

Chen Z, Uchiyama K, Hobo T (2002) J Chromatogr A 924:83–91

Chen Z, Hayashi K, Ywasaki Y, Kurita R, Niwa O, Sunagawa K (2005) Electroanalysis 17:231–238

Yeo LY, Lastochkin D, Wang SC, Chang H-C (2004) Phys Rev Lett 92:133902–133904

Lasen G, Velarde-Ortiz R, Minchow K, Barrero A, Loscertales LG (2003) J Am Chem Soc 125:1154–1155

Loscertales IG, Barrero A, Guerrero I, Cortijo R, Marquez M, Ganan-Calvo AM (2002) Science 295:1695

Acknowledgments

We thank Dr Albert E. Miller, University of Notre Dame, for use of his electrochemical instrument; Dr William Boggess, University of Notre Dame, for the injector used in this study, and Mr Katsuyashi Hayashi, NTT Microsystem Integration Labs, for valuable discussion on the sensor. This work is supported by the Center for Microfluidics and Medical Diagnostics at the University of Notre Dame.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Z., Wang, P. & Chang, HC. An electro-osmotic micro-pump based on monolithic silica for micro-flow analyses and electro-sprays. Anal Bioanal Chem 382, 817–824 (2005). https://doi.org/10.1007/s00216-005-3130-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-005-3130-7