Abstract

Multiple elastic shock waves carry the information on elastic properties under dynamic extreme conditions, but may complicate the interpretation of wave structure including the elastic–plastic transition. On the basis of the acoustic wave-equation analysis, we predict the absence or presence of multiple elastic shock waves in a single crystal subjected to shock loading along a specific crystallographic orientation. Typical FCC and BCC single crystals are taken as validation and application cases. Large-scale molecular dynamics simulations are performed for Cu and Ta; double-wave or triple-wave structures of elastic shock waves (quasilongitudinal and quasitransverse) are observed in the simulations, and the multi-wave structures are in excellent agreement with the wave-equation analysis. Also, the acoustic wave-equation analysis is used to analyze MD calculations, as well as the complex structure of the shock wave during plastic deformation. Free-surface velocity history, transverse velocity history of free surface, and ultrafast X-ray diffraction are explored as experimental means to resolve multiple elastic shock waves.

Similar content being viewed by others

Data availability statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Abbreviations

- \({\textbf {a}}_i\) :

-

Unit direction vector of \({\textbf {s}}\)

- \({\textbf {a}}_{\textrm{L}}\) :

-

Unit direction vector of the L/QL wave

- \(c_{ijkl}\), \(C_{ij}\) :

-

The ijkl- and ij-component of an elastic stiffness tensor

- d :

-

The distance between sample and X-ray detector

- F :

-

Structure vector

- \(F^{*}\) :

-

Complex conjugate of F

- I :

-

Diffraction intensity

- L/QL:

-

Longitudinal/quasilongitudinal

- m :

-

Atomic mass

- \({\textbf {n}}\) :

-

Unit vector along the x-axis

- N :

-

Number of atoms considered in V

- \({\textbf {p}}\) :

-

Unit vector for the [100] orientation closest relative to loading direction

- \({\textbf {q}}\) :

-

Scattering vector

- \({\textbf {r}}\) :

-

Coordinates

- \({\textbf {R}}\) :

-

Rotation matrix

- \({\textbf {s}}\) :

-

Displacement vector at \({\textbf {r}}\)

- \(s_i\) :

-

The ith-component of displacement for the planar acoustic wave

- \(S_i\) :

-

Amplitude of \(s_i\)

- S1, S2, S3:

-

Shock states 1, 2, and 3, respectively

- T/QT:

-

Transverse/quasitransverse

- \(u_x\), \(u_y\), \(u_z\) :

-

Particle velocity components of a shock wave

- \(u_x^{(1)}\) :

-

Particle velocity component of S1 along the x-axis

- \(u_{\textrm{p}}\) :

-

Particle velocity of a steady shock state

- \(u_{\textrm{fs}}\) :

-

Free-surface velocity

- \({\textbf {u}}_1, {\textbf {u}}_2, {\textbf {u}}_3\) :

-

Particle velocity vectors of different shock states: \({\textbf {u}}_1 = \psi _1{\textbf {a}}_1\), \({\textbf {u}}_2 = {\textbf {u}}_1 + \psi _2{\textbf {a}}_2\), and \({\textbf {u}}_3 = {\textbf {u}}_2 + \psi _3{\textbf {a}}_3\)

- U:

-

Unshocked region

- \(v_{\textrm{c}}\) :

-

Acoustic wave velocity

- \(v_{\textrm{cL}}^{(0)}\), \(v_{\textrm{cL}}^{(1)}\) :

-

L/QL acoustic wave velocities for U and S1, respectively

- \(v_{\textrm{sL}}^{(1)}\) :

-

L/QL shock velocity for S1

- V :

-

The volume of a bin

- \(\alpha _{\textrm{cL}}\) :

-

The angle between \({\textbf {a}}_{\textrm{L}}\) and \({\textbf {n}}\) for L/QL acoustic wave in U

- \(\alpha _{\textrm{sL}}\) :

-

The angle between particle velocity and shock direction for S1

- \(\beta ^{(0)}\), \(\beta ^{(1)}\), \(\beta ^{(2)}\), \(\beta ^{(3)}\) :

-

The angles between the shock direction and \({\textbf {p}}\) for U, S1, S2, and S3, respectively

- \(\gamma _{xy}\), \(\gamma _{xz}\) :

-

The xy- and xz-component of shear strain

- \(\gamma \) :

-

Azimuthal angle

- \(\delta _{ik}\) :

-

The Kronecker delta function

- \(\eta _{\textrm{cL}}\) :

-

Acoustic wave parameter for U, equal to \((u_{\textrm{p}}-\psi _{\textrm{L}}{} {\textbf {a}}_{\textrm{L}}\cdot {\textbf {n}})/u_{\textrm{p}}\times 100\%\)

- \(\eta _{\textrm{sL}}\) :

-

Shock wave parameter for S1, equal to \([u_{\textrm{p}}-u_x^{(1)}]/u_{\textrm{p}}\times 100\%\)

- \(\lambda \) :

-

X-ray wavelength

- \(\mu _{12}, \mu _{23}\) :

-

Difference parameters between different loading states, \(\mu _{12} = |{\textbf {u}}_1\times {\textbf {u}}_2|\) and \(\mu _{23} = |{\textbf {u}}_2\times {\textbf {u}}_3|\)

- 2\(\theta \) :

-

Diffraction angle

- \(\rho \) :

-

Material density

- \(\sigma _{ij}\) :

-

The ij-component of a stress tensor; or a stress tensor

- \(\phi ^{(0)}\), \(\phi ^{(1)}\), \(\phi ^{(2)}\), \(\phi ^{(3)}\) :

-

The angles between the y-axis and the projection of \({\textbf {p}}\) onto the yz-plane for U, S1, S2, and S3, respectively

- \(\psi _1\), \(\psi _2\), \(\psi _3\) :

-

Weight factors for the first, second, and third wave modes, respectively

- \(\psi _{\textrm{L}}\) :

-

Weight factor for the L/QL wave

References

Kanel, G.I., Shcherban, V.V.: Plastic deformation and cleavage rupture of armco iron in a shock wave. Combust. Explos. Shock Waves 16, 439–446 (1980). https://doi.org/10.1007/BF00742994

Ye, S.J., Chai, H.W., Xiao, X.H., Cai, Y., Yao, X.H., Luo, S.N.: Spallation of polycarbonate under plate impact loading. J. Appl. Phys. 126(8), 085105 (2019). https://doi.org/10.1063/1.5108965

Cai, Y., Wu, H.A., Luo, S.N.: Spall strength of liquid copper and accuracy of the acoustic method. J. Appl. Phys. 121(10), 105901 (2017). https://doi.org/10.1063/1.4978251

Fortov, V.E., Lomonosov, I.V.: Shock waves and equations of state of matter. Shock Waves 20(1), 53–71 (2010). https://doi.org/10.1007/s00193-009-0224-8

Walsh, J.M., Christian, R.H.: Equation of state of metals from shock wave measurements. Phys. Rev. 97(6), 1544 (1955). https://doi.org/10.1103/PhysRev.97.1544

Asay, B. (ed.): Shock Wave Science and Technology Reference Library, Vol. 5: Non-shock Initiation of Explosives. Springer, Berlin (2009). https://doi.org/10.1007/978-3-540-87953-4

Sheffield, S.A., Gustavsen, R.L., Anderson, M.U.: Shock loading of porous high explosives. In: Davison, L., Horie, Y., Shahinpoor, M. (eds.) High-Pressure Shock Compression of Solids IV, pp. 23–61. Springer (1997). https://doi.org/10.1007/978-1-4612-2292-7

Settles, G.S., Keane, B.T., Anderson, B.W., Gatto, J.A.: Shock waves in aviation security and safety. Shock Waves 12(4), 267–275 (2003). https://doi.org/10.1007/s00193-002-0162-1

Fortov, V.E., Kostin, V.V., Eliezer, S.: Spallation of metals under laser irradiation. J. Appl. Phys. 70(8), 4524–4531 (1991). https://doi.org/10.1063/1.349087

Ishizaki, R., Nishihara, K.: Propagation of a rippled shock wave driven by nonuniform laser ablation. Phys. Rev. Lett. 78(10), 1920 (1997). https://doi.org/10.1103/PhysRevLett.78.1920

Berthe, L., Fabbro, R., Peyre, P., Bartnicki, E.: Wavelength dependent of laser shock-wave generation in the water-confinement regime. J. Appl. Phys. 85(11), 7552–7555 (1999). https://doi.org/10.1063/1.370553

Nakagawa, A., Kumabe, T., Ogawa, Y., Hirano, T., Kawaguchi, T., Ohtani, K., Nakano, T., Sato, C., Yamada, M., Washio, T., Arafune, T., Teppei, T., Atsushi, K., Satomi, S., Takayama, K., Tominaga, T.: Pulsed laser-induced liquid jet: evolution from shock/bubble interaction to neurosurgical application. Shock Waves 27(1), 1–14 (2017). https://doi.org/10.1007/s00193-016-0696-2

Preston, D.L., Tonks, D.L., Wallace, D.C.: Model of plastic deformation for extreme loading conditions. J. Appl. Phys. 93(1), 211–220 (2003). https://doi.org/10.1063/1.1524706

Chen, S., Li, Y.X., Zhang, N.B., Huang, J.W., Hou, H.M., Ye, S.J., Zhong, T., Zeng, X.L., Fan, D., Lu, L., Wang, L., Sun, T., Fezzaa, K., Zhang, Y.Y., Tang, M.X., Luo, S.N.: Capture deformation twinning in Mg during shock compression with ultrafast synchrotron x-ray diffraction. Phys. Rev. Lett. 123(25), 255501 (2019). https://doi.org/10.1103/PhysRevLett.123.255501

Cai, Y., Wang, L., Wu, H.A., Zhu, M.H., Liu, C.L., Luo, S.N.: Homogeneous crystal nucleation in liquid copper under quasi-isentropic compression. Phys. Rev. B 92(1), 014108 (2015). https://doi.org/10.1103/PhysRevB.92.014108

Barker, L.M., Hollenbach, R.E.: Shock wave study of the \(\alpha \)\(\rightleftharpoons \)\(\varepsilon \) phase transition in iron. J. Appl. Phys. 45(11), 4872–4887 (1974). https://doi.org/10.1063/1.1663148

Erskine, D.J., Nellis, W.J.: Shock-induced martensitic phase transformation of oriented graphite to diamond. Nature 349(6307), 317–319 (1991). https://doi.org/10.1038/349317a0

Chen, J., Tschopp, M.A., Dongare, A.M.: Shock wave propagation and spall failure of nanocrystalline Cu/Ta alloys: effect of ta in solid-solution. J. Appl. Phys. 122(22), 225901 (2017). https://doi.org/10.1063/1.5001761

Tang, X.C., Jian, W.R., Huang, J.R., Zhao, F., Li, C., Xiao, X.H., Yao, X.H., Luo, S.N.: Spall damage of a Ta particle-reinforced metallic glass matrix composite under high strain rate loading. Mater. Sci. Eng. A 711, 284–292 (2018). https://doi.org/10.1016/j.msea.2017.11.032

Yang, H.T., Lu, Z.L., Bie, B.X., Fu, Z.Y., Yue, J.L., Huang, X.Z.: Microstructure and damage evolution of SiCf/PyC/SiC and SiCf/Bn/SiC mini-composites: a synchrotron x-ray computed microtomography study. Ceram. Int. 45(9), 11395–11402 (2019). https://doi.org/10.1016/j.ceramint.2019.03.004

Tan, J., Lu, L., Li, H.Y., Xiao, X.H., Li, Z., Luo, S.N.: Anisotropic deformation and damage of dual-phase Ti-6Al-4V under high strain rate loading. Mater. Sci. Eng. A 742, 532–539 (2019). https://doi.org/10.1016/j.msea.2018.10.088

Gruzdkov, Y.A., Gupta, Y.M.: Shock wave initiation of pentaerythritol tetranitrate single crystals: mechanism of anisotropic sensitivity. J. Phys. Chem. A 104(47), 11169–11176 (2000). https://doi.org/10.1021/jp0019613

Rohde, R.W., Butcher, B.M., Holland, J.R., Karnes, C.H. (eds.): Metallurgical Effects at High Strain Rates. Springer, Berlin (2012). https://doi.org/10.1007/978-1-4615-8696-8

Grady, M.E., Beiermann, B.A., Moore, J.S., Sottos, N.R.: Shockwave loading of mechanochemically active polymer coatings. ACS Appl. Mater. Interfaces 6(8), 5350–5355 (2014). https://doi.org/10.1021/am406028q

Meyers, M.A., Staudhammer, K.P., Murr, L.E.: Metallurgical Applications of Shock-Wave and High-Strain-Rate Phenomena. Marcel Dekker, New York (1986)

Whitham, G.B.: On the propagation of shock waves through regions of non-uniform area or flow. J. Fluid Mech. 4(4), 337–360 (1958). https://doi.org/10.1017/S0022112058000495

Wu, C.C., Roberts, P.H.: Shock-wave propagation in a sonoluminescing gas bubble. Phys. Rev. Lett. 70(22), 3424 (1993). https://doi.org/10.1103/PhysRevLett.70.3424

Davison, L.: Fundamentals of Shock Wave Propagation in Solids. Springer, Berlin (2008). https://doi.org/10.1007/978-3-540-74569-3

Wang, C.J., Kuo, Y.R., Wu, R.W., Liu, R.T., Hsu, S.C., Wang, F.S., Yang, K.D.: Extracorporeal shockwave treatment for chronic diabetic foot ulcers. J. Surg. Res. 152(1), 96–103 (2009). https://doi.org/10.1016/j.jss.2008.01.026

Luo, S.N., Germann, T.C., Desai, T.G., Tonks, D.L., An, Q.: Anisotropic shock response of columnar nanocrystalline Cu. J. Appl. Phys. 107(12), 123507 (2010). https://doi.org/10.1063/1.3437654

Zhakhovsky, V.V., Budzevich, M.M., Inogamov, N.A., Oleynik, I.I., White, C.T.: Two-zone elastic-plastic single shock waves in solids. Phys. Rev. Lett. 107(13), 135502 (2011). https://doi.org/10.1103/PhysRevLett.107.135502

Li, C., Li, B., Huang, J.Y., Ma, H.H., Zhu, M.H., Zhu, J., Luo, S.N.: Spall damage of a mild carbon steel: effects of peak stress, strain rate and pulse duration. Mater. Sci. Eng. A 660, 139–147 (2016). https://doi.org/10.1016/j.msea.2016.02.080

Gunkelmann, N., Rosandi, Y., Ruestes, C.J., Bringa, E.M., Urbassek, H.M.: Compaction and plasticity in nanofoams induced by shock waves: a molecular dynamics study. Comput. Mater. Sci. 119, 27–32 (2016). https://doi.org/10.1016/j.commatsci.2016.03.035

Jones, O.E., Mote, J.D.: Shock-induced dynamic yielding in copper single crystals. J. Appl. Phys. 40(12), 4920–4928 (1969). https://doi.org/10.1063/1.1657314

Boettger, J.C., Wallace, D.C.: Metastability and dynamics of the shock-induced phase transition in iron. Phys. Rev. B 55(5), 2840 (1997). https://doi.org/10.1103/PhysRevB.55.2840

Jensen, B.J., Gray, G.T., III., Hixson, R.S.: Direct measurements of the \(\alpha \)-\(\epsilon \) transition stress and kinetics for shocked iron. J. Appl. Phys. 105(10), 103502 (2009). https://doi.org/10.1063/1.3110188

Lee, W.H., Yao, X.H., Jian, W.R., Han, Q.: High-velocity shock compression of SiC via molecular dynamics simulation. Comput. Mater. Sci. 98, 297–303 (2015). https://doi.org/10.1016/j.commatsci.2014.11.029

Zhang, Y.Y., Li, Y.X., Fan, D., Zhang, N.B., Huang, J.W., Tang, M.X., Cai, Y., Zeng, X.L., Sun, T., Fezzaa, K., Chen, S., Luo, S.N.: Ultrafast x-ray diffraction visualization of B1-B2 phase transition in KCl under shock compression. Phys. Rev. Lett. 127(4), 045702 (2021). https://doi.org/10.1103/PhysRevLett.127.045702

Arman, B., Luo, S.N., Germann, T.C., Çağın, T.: Dynamic response of \(\rm Cu_{64}Zr_{54}\) metallic glass to high-strain-rate shock loading: plasticity, spall, and atomic-level structures. Phys. Rev. B 81(14), 144201 (2010). https://doi.org/10.1103/PhysRevB.81.144201

Bringa, E.M., Cazamias, J.U., Erhart, P., Stölken, J., Tanushev, N., Wirth, B.D., Rudd, R.E., Caturla, M.J.: Atomistic shock Hugoniot simulation of single-crystal copper. J. Appl. Phys. 96(7), 3793–3799 (2004). https://doi.org/10.1063/1.1789266

Johnson, J.N.: Shock propagation produced by planar impact in linearly elastic anisotropic media. J. Appl. Phys. 42(13), 5522–5530 (1971). https://doi.org/10.1063/1.1659974

Johnson, J.N.: Calculation of plane-wave propagation in anisotropic elastic-plastic solids. J. Appl. Phys. 43(5), 2074–2082 (1972). https://doi.org/10.1063/1.1661456

Musgrave, M.J.P.: On the propagation of elastic waves in aeolotropic media i. General principles. Proc. R. Soc. Lond. A Math. Phys. Sci. 226(1166), 339–355 (1954). https://doi.org/10.1098/rspa.1954.0258

Musgrave, M.J.P.: Crystal Acoustics. Acoustical Society of America, New York (2003)

Luzin, A.A.N.: Elastic forerunners of plastic waves propagated in nonsymmetric directions of a crystal. Combust. Explos. Shock Waves 11(6), 744–750 (1975). https://doi.org/10.1007/BF00744773

Fedorov, F.I.: Theory of Elastic Waves in Crystals. Springer, Berlin (2013). https://doi.org/10.1007/978-1-4757-1275-9

Winey, J.M., Gupta, Y.M.: Nonlinear anisotropic description for shocked single crystals: thermoelastic response and pure mode wave propagation. J. Appl. Phys. 96(4), 1993–1999 (2004). https://doi.org/10.1063/1.1767294

Long, X.J., Cai, Y., Jian, W.R., Wang, L., Luo, S.N.: Acoustic and double elastic shock waves in single-crystal graphene. J. Appl. Phys. 127(5), 055101 (2020). https://doi.org/10.1063/1.5132925

Sliwa, M., McGonegle, D., Wehrenberg, C., Bolme, C.A., Heighway, P.G., Higginbotham, A., Lazicki, A., Lee, H.J., Nagler, B., Park, H.S., Rudd, R.E., Suggit, M.J., Swift, D., Tavella, F., Zepeda-Ruiz, L., Remington, B.A., Wark, J.S.: Femtosecond X-ray diffraction studies of the reversal of the microstructural effects of plastic deformation during shock release of tantalum. Phys. Rev. Lett. 120(26), 265502 (2018). https://doi.org/10.1103/PhysRevLett.120.265502

Xu, Y.F., Hu, S.C., Cai, Y., Luo, S.N.: Origins of plastic shock waves in single-crystal Cu. J. Appl. Phys. 131(11), 115901 (2022). https://doi.org/10.1063/5.0080757

An, Q., Ravelo, R., Germann, T.C., Han, W.Z., Luo, S.N., Tonks, D.L., Goddard, I.W.A.: Shock compression and spallation of single crystal tantalum. AIP Conference Proceedings 1426, 1259–1262 (2012)

Mishin, Y., Mehl, M.J., Papaconstantopoulos, D.A., Voter, A.F., Kress, J.D.: Structural stability and lattice defects in copper: Ab initio, tight-binding, and embedded-atom calculations. Phys. Rev. B 63(22), 224106 (2001). https://doi.org/10.1103/PhysRevB.63.224106

Ravelo, R., Germann, T.C., Guerrero, O., An, Q., Holian, B.L.: Shock-induced plasticity in tantalum single crystals: interatomic potentials and large-scale molecular-dynamics simulations. Phys. Rev. B 88(13), 134101 (2013). https://doi.org/10.1103/PhysRevB.88.134101

Meyers, M.A., Chawla, K.K.: Mechanical Behavior of Materials. Cambridge University Press, Cambridge (2008). https://doi.org/10.1017/CBO9780511810947

Li, X.Y., Wei, Y.J., Lu, L., Lu, K., Gao, H.J.: Dislocation nucleation governed softening and maximum strength in nano-twinned metals. Nature 464(7290), 877–880 (2010). https://doi.org/10.1038/nature08929

An, Q., Luo, S.N., Han, L.B., Zheng, L., Tschauner, O.: Melting of Cu under hydrostatic and shock wave loading to high pressures. J. Phys. Condens. Matter 20(9), 095220 (2008). https://doi.org/10.1088/0953-8984/20/9/095220

Cai, Y., Wu, H.A., Luo, S.N.: Cavitation in a metallic liquid: homogeneous nucleation and growth of nanovoids. J. Chem. Phys. 140(21), 214317 (2014). https://doi.org/10.1063/1.4880960

Cai, Y., Huang, J.Y., Wu, H.A., Zhu, M.H., Goddard, W.A., III., Luo, S.N.: Tensile strength of liquids: equivalence of temporal and spatial scales in cavitation. J. Phys. Chem. Lett. 7(5), 806–810 (2016). https://doi.org/10.1021/acs.jpclett.5b02798

Wang, L., Zhao, F., Zhao, F.P., Cai, Y., An, Q., Luo, S.N.: Grain boundary orientation effects on deformation of Ta bicrystal nanopillars under high strain-rate compression. J. Appl. Phys. 115(5), 053528 (2014). https://doi.org/10.1063/1.4864427

Florando, J.N., Barton, N.R., El-Dasher, B.S., McNaney, J.M., Kumar, M.: Analysis of deformation twinning in tantalum single crystals under shock loading conditions. J. Appl. Phys. 113(8), 083522 (2013). https://doi.org/10.1063/1.4792227

Liu, C.M., Xu, C., Cheng, Y., Chen, X.R., Cai, L.C.: The effect of vacancies on melting properties of tantalum via molecular dynamics simulations. Appl. Phys. A 122(1), 22 (2016). https://doi.org/10.1007/s00339-015-9550-0

Ravelo, R., An, Q., Germann, T.C., Holian, B.L.: Large-scale molecular dynamics simulations of shock induced plasticity in tantalum single crystals. AIP Conf. Proc. 1426, 1263–1266 (2012). https://doi.org/10.1063/1.3686510

Plimpton, S.: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117(1), 1–19 (1995). https://doi.org/10.1006/jcph.1995.1039

Hirel, P.: Atomsk: a tool for manipulating and converting atomic data files. Comput. Phys. Commun. 197, 212–219 (2015). https://doi.org/10.1016/j.cpc.2015.07.012

Luo, S.N., An, Q., Germann, T.C., Han, L.B.: Shock-induced spall in solid and liquid Cu at extreme strain rates. J. Appl. Phys. 106(1), 013502 (2009). https://doi.org/10.1063/1.3158062

Wen, P., Tao, G., Spearot, D.E., Phillpot, S.R.: Molecular dynamics simulation of the shock response of materials: A tutorial. J. Appl. Phys. 131(5), 051101 (2022). https://doi.org/10.1063/5.0076266

Engler, O., Randle, V.: Introduction to Texture Analysis: Macrotexture, Microtexture, and Orientation Mapping. CRC Press, Boca Raton (2009)

Jc, E., Tang, M.X., Fan, D., Wang, L., Luo, S.N.: Deformation of metals under dynamic loading: characterization via atomic-scale orientation mapping. Comput. Mater. Sci. 153, 338–347 (2018). https://doi.org/10.1016/j.commatsci.2018.06.020

Shinoda, W., Shiga, M., Mikami, M.: Rapid estimation of elastic constants by molecular dynamics simulation under constant stress. Phys. Rev. B 69(13), 134103 (2004). https://doi.org/10.1103/PhysRevB.69.134103

Sichani, M.M., Spearot, D.E.: A molecular dynamics study of dislocation density generation and plastic relaxation during shock of single crystal Cu. J. Appl. Phys. 120(4), 045902 (2016). https://doi.org/10.1063/1.4959075

Kim, K.S., Clifton, R.J., Kumar, P.: A combined normal-and transverse-displacement interferometer with an application to impact of y-cut quartz. J. Appl. Phys. 48(10), 4132–4139 (1977). https://doi.org/10.1063/1.323448

Jc, E., Wang, L., Chen, S., Zhang, Y.Y., Luo, S.N.: GAPD: a GPU-accelerated atom-based polychromatic diffraction simulation code. J. Synchrotron Radiat. 25(2), 604–611 (2018). https://doi.org/10.1107/S1600577517016733

Tang, M.X., Zhang, Y.Y., Jc, E., Luo, S.N.L.: Simulations of X-ray diffraction of shock-compressed single-crystal tantalum with synchrotron undulator sources. J. Synchrotron Radiat. 25(3), 748–756 (2018). https://doi.org/10.1107/S160057751800499X

Tsvankin, I.D., Chesnokov, E.M.: Plane wave propagation in nonlinear-elastic anisotropic media. Geophys. J. Int. 91(2), 413–427 (1987). https://doi.org/10.1111/j.1365-246X.1987.tb05235.x

Chhabildas, L.C., Swegle, J.W.: Dynamic pressure-shear loading of materials using anisotropic crystals. J. Appl. Phys. 51(9), 4799–4807 (1980). https://doi.org/10.1063/1.328312

Warren, B.E.: X-ray Diffraction. Courier Corporation, New York (1990)

Prince, E.: International Tables for Crystallography, Volume C: Mathematical, Physical and Chemical Tables. Springer, Berlin (2004). https://doi.org/10.1107/97809553602060000103

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 12102491 and 11627901). Computations were performed at the PIMS Supercomputing Center.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by P. Hazell.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: More details of wave-equation analysis

Substituting (2) into (1) yields

where \(\delta _{ik}\) is the Kronecker delta function. For a plane wave propagating along the x-axis, \({\textbf {n}} = (1,0,0)\); \(c_{ijkl}\) at a new coordinate system can be obtained as

where Q is the rotation matrix from new coordinate system to the original coordinate system, \(c_{mnpq}\) is the elastic stiffness tensor at the original coordinate system.

Equation (7) can be simplified to [43]

where \({\textbf {a}}=(a_x,\,a_y,\,a_z)\) is the unit direction vector for \({\textbf {s}}\).

To obtain the nonzero solutions for (9), the determinant of the matrix should equal zero, i.e.,

According to the Cardano’s formula, three solutions for \(v_{\textrm{c}}\), \(v_{\mathrm{c_1}}\), \(v_{\mathrm{c_2}}\), and \(v_{\mathrm{c_3}}\) can be obtained from (10), and here \(v_{\mathrm{c_1}}>v_{\mathrm{c_2}}\ge v_{\mathrm{c_3}}\). According to (9), the unit direction vector, \({\textbf {a}}_1\), \({\textbf {a}}_2\), and \({\textbf {a}}_3\) can be obtained as (3).

For \(C_{15}=0\) and \(C_{56}=0\), the Cardano’s formula is not applicable, and (10) is written as

Three solutions for \(v_{\textrm{c}}\) can be obtained as well, and \(v_{\mathrm{c_1}}>v_{\mathrm{c_2}}\ge v_{\mathrm{c_3}}\).

Appendix 2: Rotation matrix

Given Euler angles \((\varphi _1,\Phi ,\varphi _2)\) [67, 68], the rotation matrix \({\textbf {R}}\) can be written as

The unit vector \({\textbf {p}}\) \((p_x,p_y,p_z)\) (corresponds to the [100] direction closest relative to the x-axis) can be calculated as

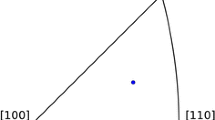

Here, \({\textbf {n}}=(1,0,0)\) is the unit vector along the x-axis. As shown in Fig. 1, the angle \(\beta \) (between \({\textbf {n}}\) and \({\textbf {p}}\)) and \(\phi \) (between the projection vector of \({\textbf {p}}\) onto the yz-plane and the y-axis) are

and

Appendix 3: Supplementary results of MD simulation for single-crystal Cu at \(u_{\textrm{p}}=0.1\) km s\(^{-1}\)

Upon the arrival of a QL wave, shear stress \(\sigma _{xy}\) is nonzero (Fig. 7e) and drives the transverse movement of atoms and shear strain \(\gamma _{xy}\) in single-crystal Cu. The profiles of particle velocity component \(u_y\) and transverse displacement \(s_y\) for [311] Cu at 45 ps are shown in Fig. 18a. In the \(\mathrm F_2F_1\) segment, \(s_y\) decreases with increasing x. Particles move transversely at \(u_y=16.88\) \(\mathrm m\,s^{-1}\). In the \(\mathrm OF_2\) segment, the transverse motion stops; \(s_y\) increases from 0 to peak P. Shear strain is calculated as \(\gamma _{xy} = \frac{\partial s_y}{\partial x}+\frac{\partial s_x}{\partial y}\). In shocked Cu, \(\frac{\partial s_x}{\partial y}=0\), so \(\gamma _{xy}=\frac{\partial s_y}{\partial x}\); \(\gamma _{xy}^{(1)}=-3.62\times 10^{-3}\) and \(\gamma _{xy}^{(2)}=4.56\times 10^{-3}\) for S1 and S2, respectively. Different from the [311] case, \(u_z\) (Fig. 7c) and shear stress \(\sigma _{xz}\) (Fig. 7f) for [321] Cu are not zero and drive transverse movement of atoms in the xz-plane and giving rise to shear strain \(\gamma _{xz}\). Figure 18b shows the profiles of transverse displacement \(s_y\), \(s_z\), and particle velocity component \(u_z\). Shear strain \(\gamma _{xy} = \frac{\partial s_y}{\partial x}+\frac{\partial s_x}{\partial y}\) and \(\gamma _{xz} = \frac{\partial s_z}{\partial x}+\frac{\partial s_x}{\partial z}\). However, partial derivative \(\frac{\partial s_x}{\partial z}=0\) and \(\frac{\partial s_x}{\partial y}=0\), so \(\gamma _{xy}=\frac{\partial s_y}{\partial x}\) and \(\gamma _{xz}=\frac{\partial s_z}{\partial x}\). In Fig. 18b, the profiles of \(s_y(x)\) and \(s_z(x)\) indicate that \(\gamma _{xy}\) and \(\gamma _{xz}\) of S1, S2, and S3 achieve a constant value. For S1, \(\gamma _{xy}^{(1)}=-2.06\times 10^{-3}\) and \(\gamma _{xz}^{(1)}=0\). For S2, \(\gamma _{xy}^{(2)}=-1.58\times 10^{-3}\) and \(\gamma _{xz}^{(2)}=-1.37\times 10^{-3}\). For S3 (\(\mathrm OF_3\)), \(\gamma _{xy}^{(3)}=3.32\times 10^{-3}\) and \(\gamma _{xz}^{(3)}=0.73\times 10^{-3}\).

a Profiles of transverse particle displacement \(s_y\) and particle velocity component \(u_y\) for [311] Cu at 45 ps. b Profiles of transverse particle displacements \(s_y\) and \(s_z\), and particle velocity component \(u_z\) for [321] Cu at 45 ps; O: impact location; \(\textrm{F}_1\): wavefront of S1; \(\textrm{F}_2\): wavefront of S2; \(\textrm{F}_3\): wavefront of S3

Position–time or \(x{-}t\) diagram for flyer plate impact loading at \(u_{\textrm{p}}=0.1\) km s\(^{-1}\). Color coding is based on particle velocity component \(u_x\); U: unshocked region; S1: elastic shock state 1; S2: elastic shock state 2; R1: release wave 1; N: a state induced by the interaction of S2 and R1

Appendix 4: Possible experimental measurements

For [311] single-crystal Cu, the wave propagation and interaction are detailed in the position–time (\(x{-}t\)) diagram in terms of particle velocity component \(u_x\), as shown in Fig. 19. The impact yields double elastic shock waves (correspond to S1 and S2) propagating into the target. The wavefront of S1 first reaches the free surface (D in Fig. 19) and then reflects at the free surface as a centered simple release fan (R1) traveling toward the opposite direction. When R1 meets S2, the interaction of R1 and S2 gives rise to a new state N. The wavefront of N travels faster than that of S2 and reaches the free surface first (E); later, the wavefront of S2 reaches the free surface (F). Thus, a triple-platform structure is observed on the \(u_{\textrm{fs}}(t)\) curve (Fig. 14a).

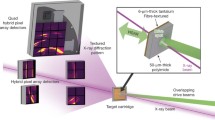

In XRD simulations with GAPD [72, 73], the diffraction intensity \(I({\textbf {q}})\) is [76]

Here, \({\textbf {q}}\) is the scattering vector. \(F({\textbf {q}})\) is the structure vector, and its complex conjugate \(F^{*}({\textbf {q}})\). G is the number of atoms in the selected area. The structure vector \(F({\textbf {q}})\) is

where f is the atomic scattering factor for X-rays [77] and \({\textbf {x}}_j\) is the position of the jth atom in the real space. According to the Bragg’s law [76], \({\textbf {q}}\) can be obtained with

where 2\(\theta \) is the diffraction angle, \(\lambda \) is the wavelength, and \(d_{hkl}\) is the interplanar spacing. For a polychromatic beam, the intensity at a specific position on a 2D detector, \(I(2\theta ,\gamma )\), is the weighted integration over the incident beam wavelength range, [\(\lambda _1, \lambda _2\)], i.e.,

Here, \(\gamma \) is the azimuthal angle (Fig. 16) and \(w(\lambda )\) is the flux fraction of the incident beam. Each set of \((2\theta ,\gamma ,\lambda )\) corresponds to a scattering vector \({\textbf {q}}\). More details including intensity projection onto a detector were presented elsewhere [72, 73].

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Q., Xu, Y.F., Hu, S.C. et al. Multiple elastic shock waves in cubic single crystals. Shock Waves 33, 337–355 (2023). https://doi.org/10.1007/s00193-023-01137-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00193-023-01137-2