Abstract

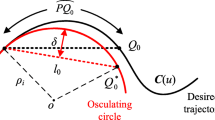

The contour following task of a multi-axis servo system is one of the most important applications of modern computer numerical control (CNC) machining. Reducing the contour error is an important content in the multi-axis contour following task. A common method to solve this problem is the cross-coupling control (CCC). Since the traditional CCC method cannot meet the requirements of tracking accuracy and contour control accuracy at large curvature positions in free-form curve machining, the main contribution of this paper is to propose a novel integrated control strategy based on arc length parameters for contour error compensation, which consists of a double-circle weighted approximation contour error estimation model based on arc length parameters module, an improved cross-coupling position command shaping controller (CPCSC) module, and an improved position error compensator (PEC) module. To improve the accuracy of contour error estimation for large free-form curvature trajectories, a double-circle weighted approximation contour error estimation model based on arc length parameters is proposed. The method first finds the nearest interpolation point by backtracking method and calculates the backward reference points by using the method based on arc length parameters. Then, the obtained backward reference points are used as the expected instruction points by the double-circle weighted approximation method, and the estimated value of contour error is calculated. Moreover, an improved structure of CPCSC is proposed. Compared with the traditional biaxial CCC structure, the advantage of this new structure is that the compensator design and stability analysis in its CCC are relatively simple, and it can be easily implemented on most current systems by reprogramming the reference position command subroutine. In addition, an improved PEC method is further proposed to reduce contour error. The main advantage of this module is that it can simultaneously improve tracking and contouring performances by compensating position errors in advance. The feasibility of the proposed integrated control strategy is verified by serval non-uniform rational B-spline (NURBS) parametric curve contour following experiments. Moreover, the results of comparative experiments indicate that the proposed integrated control strategy can significantly improve the tracking and contour control accuracy of biaxial contour following tasks compared with none-CCC method and CCC method, and has better contour control performance in large curvature positions.

Similar content being viewed by others

Data availability

The authors have no financial or proprietary interests in any data and material discussed in this article.

Code availability

The authors have no financial or proprietary interests in any code discussed in this article.

References

Abishek EB, Raja AVP, Kumar KPC, Stephen AC, Raaza A (2017) Study and analysis of conformal antennas for vehicular communication applications. ARPN J Eng Appl Sci 12(8):2428–2433. https://www.researchgate.net/publication/324983169_Study_and_analysis_of_conformal_antennas_for_vehicular_communication_applications

Abishek BE, Hashim ZA, Prasath HS, Stephen CA, Kumar PCK (2018) Design of conformal microstrip patch antenna for vehicle tracking. Int J Eng Technol 7(3.27):189–191. https://doi.org/10.14419/ijet.v7i3.27.17758

Abishek BE, Raaza A, Rajendran V (2018) Simulation analysis of circular and linearly polarized patch antenna for vehicular SATCOM. J Dyn Control Syst 10(12):800–803. https://www.researchgate.net/publication/334670433_Simulation_Analysis_of_Circular_and_Linearly_Polarized_Patch_Antenna_for_Vehicular_SATCOM

Kumar S, Sandeep K, Sujeeth S, Punitha N, Padmanabhan S, Vijayan V, Baskar S (2023) A sustainable development perspective and evaluating the impact of laser cladding parameters on mild steel. In: E3S Web of Conferences, vol 399. EDP Sciences, p 03013. https://doi.org/10.1051/e3sconf/202339903013

Anil KC, Kumaraswany J, Reddy M, Prakash B (2022) Mechanical behaviour and fractured surface analysis of bauxite residue & graphite reinforced aluminium hybrid composites. Frattura ed IntegritàStrutturale 62:168–179. https://doi.org/10.3221/IGF-ESIS.62.12

Masory O (1986) Improving contouring accuracy of NC/CNC systems with additional velocity feed forward loop. ASME J Eng Ind 108(3):227–230. https://doi.org/10.1115/1.3187068

Fujimoto H, Hori Y, Kawamura A (2001) Perfect tracking control based on multirate feedforward control with generalized sampling periods. IEEE Trans Ind Electron 48(3):636–644. https://doi.org/10.1109/41.925591

Tomizuka M (1987) Zero phase error tracking algorithm for digital control. ASME J Dyn Sys Meas Control 109(1):65–68. https://doi.org/10.1115/1.3143822

Koren Y, Lo CC (1991) Variable-gain cross-coupling controller for contouring. CIRP Ann 40(1):371–374. https://doi.org/10.1016/S0007-8506(07)62009-5

Zhang T, Wu CC, He YW, Zou YB, Liao CL (2021) Gain parameters optimization strategy of cross-coupling controller based on deep reinforcement learning. Eng Optim 54(5):727–742. https://doi.org/10.1080/0305215X.2021.1897801

Koren Y (1980) Cross-coupling biaxial computer control for manufacturing systems. ASME J Dyn Sys Meas Control 102(4):265–272. https://doi.org/10.1115/1.3149612

Srinivasan K, Kulkarni PK (1990) Cross-coupled control of biaxial feed drive servomechanisms. ASME J Dyn Sys Meas Control 112(2):225–232. https://doi.org/10.1115/1.2896129

Chuang HY, Liu CH (1991) Cross-coupled adaptive feedrate control for multiaxis machine tools. ASME J Dyn Sys Meas Control 113(3):451–457. https://doi.org/10.1115/1.2896431

Yeh SS, Hsu PL (2002) Estimation of the contouring error vector for the cross-coupled control design. IEEE/ASME Trans Mechatron 7(1):44–51. https://doi.org/10.1109/3516.990886

Chen SL, Liu HL, Ting SC (2002) Contouring control of biaxial systems based on polar coordinates. IEEE/ASME Trans Mechatron 7(3):329–345. https://doi.org/10.1109/TMECH.2002.802723

Erkorkmaz K, Yeung CH, Altintas Y (2005) Virtual CNC system. Part II. High speed contouring application. Int J Mach Tools Manuf 46(10):1124–1138. https://doi.org/10.1016/j.ijmachtools.2005.08.001

Cheng MY, Lee CC (2007) Motion controller design for contour-following tasks based on real-time contour error estimation. IEEE Trans Ind Electron 54(3):1686–1695. https://doi.org/10.1109/TIE.2007.894691

Chen SL, Wu KC (2007) Contouring control of smooth paths for multiaxis motion systems based on equivalent errors. IEEE Trans Control Syst Technol 15(6):1151–1158. https://doi.org/10.1109/TCST.2007.899719

Yang JZ, Li ZX (2011) A novel contour error estimation for position loop-based cross-coupled control. IEEE/ASME Trans Mechatron 16(4):643–655. https://doi.org/10.1109/TMECH.2010.2048718

Zhao GY, An HJ, Zhao QZ (2013) Contour error coupled-control strategy based on line interpolation and curve interpolation. J Comput 8(6):1512–1519. https://doi.org/10.4304/jcp.8.6.1512-1519

Li B, Wang TY, Wang P (2021) Cross-coupling control based on real-time double circle contour error estimation for biaxial motion system. Meas Control 54(3-4):324–335. https://doi.org/10.1177/0020294021993830

Chen HR, Cheng MY, Wu CH, Su KH (2016) Real time parameter based contour error estimation algorithms for free form contour following. Int J Mach Tools Manuf 102:1–8. https://doi.org/10.1016/j.ijmachtools.2015.11.009

Kulkarni PK, Srinivasan K (1989) Optimal contouring control of multi-axial feed drive servomechanisms. J Eng Ind 111:140–148. https://doi.org/10.1115/1.3188743

Lo CC (1992) Cross-coupling control of multi-axis manufacturing systems. Ph.D. thesis. University of Michigan, Ann Arbor, MI

Yeh ZM (1998) A cross-coupled bistage fuzzy controller for biaxis servomechanism control. Fuzzy Sets Syst 97:265–275. https://doi.org/10.1016/S0165-0114(96)00367-3

Chuang HY, Liu CH (1992) A model-referenced adaptive control strategy for improving contour accuracy of multiaxis machine tools. IEEE Trans Ind Appl 28:221–227. https://doi.org/10.1109/28.120234

Barton KL, Alleyne AG (2008) A cross-coupled iterative learning control design for precision motion control. IEEE Trans Control Syst Technol 16(6):1218–1231. https://doi.org/10.1109/TCST.2008.919433

Yeh SS, Hsu PL (1999) Theory and applications of the robust cross-coupled control design. ASME J Dynam Syst Meas Control 121:524–530. https://doi.org/10.1115/1.2802506

Fang RW, Chen JS (2002) A cross-coupling controller using an H-infinity scheme and its application to a two-axis direct-drive robot. J Robot Syst 19:483–497. https://doi.org/10.1002/rob.10055

Yang JZ, Zhang DJ, Li ZI (2008) Position loop-based cross-coupled control for high-speed machining. World Cong Intell Control Automat 2008:4285–4290. https://doi.org/10.1109/WCICA.2008.4593612

Yeh SS, Hsu PL (1999) Analysis and design of the integrated controller for precise motion systems. IEEE Trans Control Syst Technol 7(6):706–717. https://doi.org/10.1109/87.799671

Yan MT, Lee MH, Yen PL (2005) Theory and application of a combined self-tuning adaptive control and cross-coupling control in a retrofit milling machine. Mechatronics 15(2):193–211. https://doi.org/10.1016/j.mechatronics.2004.07.011

Cheng MY, Su KH, Wang SF (2008) Contour error reduction for free-form contour following tasks of biaxial motion control systems. Robot Comput Integr Manuf 25(2):323–333. https://doi.org/10.1016/j.rcim.2008.01.003

Su KH, Cheng MY (2008) Contouring accuracy improvement using cross- coupled control and position error compensator. Int J Mach Tools Manuf 48(12–13):1444–1453. https://doi.org/10.1016/j.ijmachtools.2008.04.008

Sun D (2003) Position synchronization of multiple motion axes with adaptive coupling control. Automatica 39(6):997–1005. https://doi.org/10.1016/S0005-1098(03)00037-2

Sun D, Tong MC (2009) A synchronization approach for the minimization of contouring errors of CNC machine tools. IEEE Trans Autom Sci Eng 6(4):720–729. https://doi.org/10.1109/TASE.2009.2021970

Zhang T, Wu CC, Zou YB (2020) Chord error constraint based integrated control strategy for contour error compensation. Front Mech Eng 15:645–658. https://doi.org/10.1007/s11465-020-0601-7

Chen CS, Chen LY (2011) Cross-coupling position command shaping control in a multi-axis motion system. Mechatronics 21(3):625–632. https://doi.org/10.1016/j.mechatronics.2011.01.004

Song DN, Zhong YG, Ma JW (2019) Third-order contour-error estimation for arbitrary free-form paths in contour-following tasks. Precis Eng 60:85–92. https://doi.org/10.1016/j.precisioneng.2019.07.009

Yang JX, Altintas Y (2015) A generalized on-line estimation and control of five-axis contouring errors of CNC machine tools. Int J Mach Tools Manuf:9–23. https://doi.org/10.1016/j.ijmachtools.2014.08.004

Shih YT, Chen CS, Lee AC (2002) A novel cross-coupling control design for Bi-axis motion. Int J Mach Tools Manuf 42(14):1539–1548. https://doi.org/10.1016/S0890-6955(02)00109-8

Cheng MY, Tsai MC, Kuo JC (2002) Real-time NURBS command generators for CNC servo controllers. Int J Mach Tools Manuf 42(7):801–813. https://doi.org/10.1016/S0890-6955(02)00015-9

Funding

This work is supported by the Key Technology Research and Development Program of Shandong Province (2023CXPT074).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Consent to participate

All authors consent to participate in the study.

Consent for publication

All authors consent to the publication of this article.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lu, Y., Fan, Y., Zhao, J. et al. Real-time arc length parameter-based integrated control strategy of contour error compensation for free-form curve CNC machining. Int J Adv Manuf Technol 131, 1769–1794 (2024). https://doi.org/10.1007/s00170-024-13030-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13030-y