Abstract

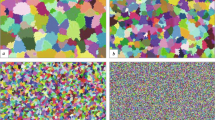

The processes of melt crystallization and conductive heat transfer during selective laser melting of a metal alloy are considered in a conjugate formulation. A mathematical model is proposed for describing the inhomogeneous temperature field for calculating the fraction of the crystalline phase during laser treatment of the surface of a metal alloy. A numerical study of laser amorphization of bulk metallic glass (BMG) by melting the surface of samples of finite dimensions has been carried out. A comparison with the known experimental data is carried out, and a qualitative agreement is obtained for the calculations on the depth of the melt pool, the homogeneity of the amorphous layer, and its location for a multicomponent alloy based on zirconium: \({Zr}_{57}{Cu}_{\mathrm{15,4}}{Ni}_{\mathrm{12,6}}{Al}_{10}{Nb}_{5}\). Potentially suitable laser scanning regimes are identified, in which the fraction of the crystalline phase in the treated layer does not increase compared to the initial one in the initial amorphous-crystalline alloy. It was found that when using the calculated modes of laser scanning, it is possible to reduce the fraction of the crystalline phase in the treated surface layer of the BMG alloy by orders of magnitude.

Similar content being viewed by others

References

Klement W Jr, Willens RH, Duwez P (1960) Non-crystalline structure in solidified gold-silicon alloys. Nature 187:869–870

Suryanarayana C, Inoue A (2012) . Metallic Glasses. 2012 Wiley-VCH Verlag GmbH & Co KGaA, Weinheim. https://doi.org/10.1002/14356007.a16_335.pub2

Davis LA (1978) Metallic Glasses. Gilman JJ, Leamy HJ (ed) (Metals Park, Ohio: American Society for Metals). p 190–223

Schroers J (2010) Processing of bulk metallic glass. Adv Mater 22(14):1566–1597

Axinte E (2012) Metallic glasses from “alchemy” to pure science: present and future of design, processing and applications of glassy metals. Mater Des 35:518–556

Hafner J (1980) Theory of the formation of metallic glasses. Phys Rev B 21(2):406–426

Otsu M, Ide Y, Sakurai J, Hata S, Takashima K (2009) Laser forming of thin metallic glass. J Solid Mech Mater Eng 3(2):387–396

Liu WD, Ye LM, Liu KX (2011) Micro-nano scale ripples on metallic glass induced by laser pulse. J Appl Phys 109(043109):1–5

Williams E, Lavery N (2017) Laser processing of bulk metallic glass: a review. J Mater Proc Tech 247:73–91

Greer A (2015) New horizons for glass formation and stability. Nature Mater 14:542–546. https://doi.org/10.1038/nmat4292)

Inoue A, Zhang T, Masumoto T (1990) Production of amorphous cylinder and sheet of La55 Al25 Ni20 alloy by a metallic mold casting method. Mater Trans, JIM 31(5):425–428

Pauly S, Löber L, Petters R, Stoica M, Scudino S, Kühn U, Eckert J (2013) Processing metallic glasses by selective laser melting. Mater Today 16(1-2). https://doi.org/10.1016/j.mattod.2013.01.018

Khmyrov RS, Podrabinnik PA, Tarasova TV, Gridnev MA, Korotkov AD, Grigoriev SN, Kurmysheva AYu, Kovalev OB, Gusarov AV (2023) Partial crystallization in a Zr-based bulk metallic glass in selective laser melting. Int J Adv Man Tech 126:5613–5631. https://doi.org/10.1007/s00170-023-11500-3

Shadowspeaker L, Shah M, Busch R (2004) On the crystalline equilibrium phases of the Zr57Cu15,4Ni12,6Al10Nb5 bulk metallic glass forming alloy. Scripta Mater 50:1035–1038. https://doi.org/10.1016/j.scriptamat.2003.12.023

Kolmogorov AN (1937) A statistical theory for the recrystallization of metals. Bull Acad Sci USSR, Ser Math 1(3):355–359

Johnson WA, Mehl RF (1939) Reaction kinetics in processes of nucleation and growth, transactions of the American Institute of Mining and Metallurgical Engineers 135:416–442

Avrami M (1941) Granulation, phase change, and microstructure kinetics of phase change III. J Chem Phys 9(2):177–184

Chen H (1978) A method for evaluating viscosities of metallic glasses from the rates of thermal transformations. J Non-Cryst Solids 27(2):257–263. https://doi.org/10.1016/0022-3093(78)90128-x

Henderson DW (1979) Thermal analysis of non-isothermal crystallization kinetics in glass forming liquids. J Non-Cryst Solids 30(3):301–315. https://doi.org/10.1016/0022-3093(79)90169-8

Málek J (1995) The applicability of Johnson-Mehl-Avrami model in the thermal analysis of the crystallization kinetics of glasses. Thermochim Acta 267:61–73. https://doi.org/10.1016/0040-6031(95)02466-2

Yang Z, Markl M, Körner C (2022) Predictive simulation of bulk metallic glass crystallization during laser powder bed fusion. Addit Manuf 59:103121. https://doi.org/10.1016/j.addma.2022.103121

Nakamura K, Watanabe T, Katayama K, Amano T (1972) Some aspects of nonisothermal crystallization of polymers. I. relationship between crystallization temperature, crystallinity, and cooling conditions. J Appl Polym Sci 16(5):1077–1091. https://doi.org/10.1002/app.1972.070160503

Nakamura K, Katayama K, Amano T (1973) Some aspects of nonisothermal crystallization of polymers. II. consideration of the isokinetic condition. J Appl Polym Sci 17(4):1031–1041. https://doi.org/10.1002/app.1973.070170404

Liu H, Jiang Q, Huo J, Zhang Y, Yang W, Li X (2020) Crystallization in additive manufacturing of metallic glasses: a review. Addit Manuf 36:101568. https://doi.org/10.1016/j.addma.2020.101568

Cherepanov AN, Popov VN, Solonenko OP (2008) Numerical analysis of the spreading and crystallization dynamics of the modified metal droplet on the substrate. Thermophys Aeromech 15(3):483–489

Niziev VG, Mirzade FKH, Panchenko VYA, Khomenko MD, Grishae RV, Pityana S, Rooyen CV (2013) Numerical study to represent non-isothermal melt-crystallization kinetics at laser-powder cladding. Model Numer Simul Mater Sci 3:61–69. https://doi.org/10.4236/mnsms.2013.32008

Gupta SC (2018) The classical Stefan problem: basic concepts, modelling and analysis with quasi-analytical solutions and methods. Elsevier

Gridnev MA, Khmyrov RS, Gusarov AV (2023) Model of heat transfer and crystallization kinetics in the heat-affected zone in vit106 alloy in selective laser melting. High Temp Mater Process 27(3). https://doi.org/10.1615/HighTempMatProc.2023048119

Cho JH, Farson DF, Milewski JO, Hollis KJ (2009) Weld pool flows during initial stages of keyhole formation in laser welding. J Phys D: Appl Phys 42(11pp):175502. https://doi.org/10.1088/0022-3727/42/17/175502

Yanenko NN (1971) The method of fractional steps, the solution of problems of mathematical physics in several variables. Springer-Verlag, Berlin

Kuznetsov GV, Sheremet MA (2010) Numerical simulation of convective heat transfer modes in a rectangular area with a heat source and conducting walls. J Heat Transfer 132(8):081401. https://doi.org/10.1115/1.4001303

Bacheeva AV, Khmyrov RS, Korotkov AD, Tarasova TV, Gusarov AV (2022) Amorphous-crystalline composite microstructure formation in Zr46Cu46Al8 alloy at the conditions of selective laser melting. Key Eng Mater Trans Tech Publications Ltd 910:959–965. https://doi.org/10.4028/p-1s59b9

Funding

This work was supported by the Russian Science Foundation (Grant Agreement No. 21–19–00295, https://rscf.ru/project/21-19-00295/).

Author information

Authors and Affiliations

Contributions

Conceptualization: OBK, AVG. Investigation: OBK, DSI. Supervision: AVG. Funding acquisition: AVG. Writing—original draft: OBK. Writing—review and editing: OBK, AVG, DSI.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kovalev, O.B., Gusarov, A.V. & Ivanenko, D.S. Modeling nonisothermal laser amorphization: a multicomponent alloy perspective. Int J Adv Manuf Technol 130, 5795–5812 (2024). https://doi.org/10.1007/s00170-024-13025-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13025-9