Abstract

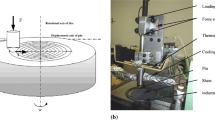

During hinges manufacturing, a particular die wear was discovered in the step of cold plastic rolling (CPR). This experimental work deals with the investigation of the tribological behaviour of tool-workpiece material pairs: a cold work tool material (X160CrMoV12) sliding against a carbon steel sheet (S235JR) used in the CPR operation. The development of a new and special tribological test designed to simulate conditions corresponding to the CPR process was accomplished. The friction tests were completed using the reciprocating sliding tribometer taking into account the opened tribosystem and the X160CrMoV12 pin sliding orientations. The SEM-EDS characterization of the pin surface revealed an abrasive wear associated with adhesive wear when the pin slides perpendicular to the rolling direction of the plate, but no relevant difference was shown in the friction coefficient values obtained by the pin sliding perpendicular or parallel to the rolling direction of the plate. Then, the influence of deposition of Ni-B 25mL/L TiO2 sol composite coating on the wear behaviour of the pin and the plate was completed. The applied coating weakens and softens the contact zone between the plate and the pin due to its low roughness (0.12 μm). Indeed, the friction coefficient is reduced to 0.2 and the pin track width decreases from approximately 1520 to 1351 μm upon a sliding distance of 65 m. Also, the coated pin provides an important protection to the S235 JR plate from wear damage as the wear volume of the friction track decreased by over 68% and the wear depth diminished by almost 42% at the end of the sliding distances.

Similar content being viewed by others

References

Yangui W, Guermazi N, Elleuch K (2017) Failure analysis of a cold work tool material slides against carbon steel in sheet metal forming process—a case study of hinges production. Int J Adv Manuf Technol 88:3151–3161

Yangui W, Guermazi N, Ktari A, Elleuch K (2022) Analysis of die-sheet contact in the rolling process. In: International Conference on Innovative Materials, Manufacturing, and Advanced Technologies. Cham, Springer Nature Switzerland, pp 179–186

Yangui W, Guermazi N, Ktari A, Elleuch K (2018b) Sheet metal forming in the case of hinge manufacturing process. Part 1: experimental study. The International Journal of Advanced Manufacturing Technology 94:2635–2643

Yangui W, Ktari A, Gammoudi M, Guermazi N, Elleuch K (2018a) Sheet metal forming in the case of hinge manufacturing process. Part 2: numerical study. Int J Adv Manuf Technol 95:367–374

Liu X, Liewald M, Becker D (2009) Effects of rolling direction and lubricant on frictionin sheet metal forming. J Tribol 131(4):04210

Trzepiecinski T (2019) A study of the coefficient of friction in steel sheets forming. Metals 9(9):988

Boher C, Le Roux S, Penazzi L, Dessain C (2012) Experimental investigation of the tribological behavior and wear mechanisms of tool steel grades in hot stamping of a high-strength boron steel. Wear 294:286–295

Mozgovoy S, Hardell J, Deng L, Oldenburg M, Prakash B (2018) Tribological behavior of tool steel under press hardening conditions using simulative tests. J Tribol 140(1):011606

Schey JA (1983) Tribology in metal working. Friction, lubrication and wear. American Society for Metals, Metals Park 173

Kalpakjian S (1985) Recent progress in metal forming tribology. CIRP annals 34(2):585–592

Azushima A, Kudo H (1995) Direct observation of contact behaviour to interpret the pressure dependence of the coefficient of friction in sheet metal forming. CIRP Annals 44(1):209–212

Andreasen JL, Bay N, De Chiffre L (1998) Quantification of galling in sheet metal forming by surface topography characterisation. Int J Mach Tool Manuf 38(5-6):503–510

Kondratiuk J, Kuhn P (2011) Tribological investigation on friction and wear behaviour of coatings for hot sheet metal forming. Wear 270(11-12):839–849

Findik F (2014) Latest progress on tribological properties of industrial materials. Mater Des 57:218–244

Mondelin A, Furet B, Rech J (2010) Characterisation of friction properties between a laminated carbon fibres reinforced polymer and a monocrystalline diamond under dry or lubricated conditions. Tribol Int 43(9):1665–1673

Lorain R, Olivier L, Poggi A, Valiorgue F, Rech J (2019) Identification of friction coefficients when drilling titanium TiAl6V4. Procedia CIRP 82:119–123

Määttä A, Vuoristo P, Mäntylä T (2001) Friction and adhesion of stainless steel strip against tool steels in unlubricated sliding with high contact load. Tribol Int 34(11):779–786

Bay N, Olsson DD, Andreasen JL (2008) Lubricant test methods for sheet metal forming. Tribol Int 41(9-10):844–853

Gåård A, Hallbäck N, Krakhmalev P, Bergström J (2010) Temperature effects on adhesive wear in dry sliding contacts. Wear 268:968–975

Bhaduri D, Batal A, Dimov SS, Zhang Z, Dong H, Fallqvist M, M'saoubi R (2017) On design and tribological behaviour of laser textured surfaces. Procedia Cirp 60:20–25

Gåård A, Krakhmalev PV, Bergström J, Hallbäck N (2007) Galling resistance and wear mechanisms–cold work tool materials sliding against carbon steel sheets. Tribol Lett 26:67–72

Gåård A, Krakhmalev P, Bergström J (2009) Influence of tool steel microstructure on origin of galling initiation and wear mechanisms under dry sliding against a carbon steel sheet. Wear 267(1-4):387–393

Van der Heide E, Schipper DJ (2003) Galling initiation due to frictional heating. Wear 254(11):1127–1133

Vitos L, Larsson K, Johansson B, Hanson M, Hogmark S (2006) An atomistic approach to the initiation mechanism of galling. Comput Mater Sci 37(3):193–197

Pettersson U, Jacobson S (2004) Friction and wear properties of micro textured DLC coated surfaces in boundary lubricated sliding. Tribol Lett 17(3):553–559

Carlsson P, Olsson MPVD (2006) PVD coatings for sheet metal forming processes—a tribological evaluation. Surf Coat Technol 200(14-15):4654–4663

Hu Z, Schubnov A, Vollertsen F (2012) Tribological behaviour of DLC-films and their application in micro deep drawing. J Mater Process Technol 212(3):647–652

Bahri A, Guermazi N, Elleuch K, Ürgen M (2015) Tribological performance of TiN coatings deposited on 304 L stainless steel used for olive-oil extraction. Wear 342:77–84

Xu C, Li Y, Wang Z, Cheng Z, Liu F (2020) The influence of self-lubricating coating during incremental sheet forming of TA1 sheet. Int J Adv Manuf Technol 110:2465–2477

Bhandarkar LR, Behera M, Mohanty PP, Sarangi SK (2021) Experimental investigation and multi-objective optimization of process parameters during machining of AISI 52100 using high performance coated tools. Measurement 172:108842

Chang K, Dong Y, Zheng G, Jiang X, Yang X, Cheng X, Liu H, Zhao G (2022) Friction and wear properties of TiAlN coated tools with different levels of surface integrity. Ceram Int 48(4):4433–4443

Xie H, Jiang B, He J, Xia X, Pan F (2016) Lubrication performance of MoS2 and SiO2 nanoparticles as lubricant additives in magnesium alloy-steel contacts. Tribol Int 93:63–70

Kallel M, Masseoud M, Vesco S, Barletta M, Elleuch K (2020) The effects of TiO2 sol concentration on single-and multiple-scratch damage in electroplated Ni–B-TiO2 sol composite coating. Ceram Int 46(3):3767–3776

Kallel M, Masseoud M, Antar Z, Fridrici V, Barletta M, Elleuch K (2021a) Tribological properties of Ni–B–TiO2 sol composite coating elaborated by sol-enhanced process: abrasive wear and impact wear. J Mater Res Technol 13:857–871

Kallel M, Antar Z, Masseoud M, Vesco S, Barletta M, Elleuch K (2021b) Comparative investigation of scratch resistance and tribological performance of Ni–B–TiO2 composite coatings prepared by conventional and novel processing methods. Ceram Int 47:14438–14454

Kallel M, Bahri A, Elleuch K (2022) Investigation on the wear resistance of Ni-B-TiO2 composite coatings for dry crushing application. In: Pakseresht A, Sharifahmadian O (eds) Adv Chem Mater Eng. IGI Global, United States of America, pp 218–244

Autay R, Kchaou M, Dammak F (2015) Friction and wear behaviour of induction hardened ISO 42CrMo4 low-alloy steel under reciprocating sliding conditions. Proc Inst Mech Eng, Part J: J Eng Tribology 229(2):115–125

Azushima A (2016) Tribology in sheet rolling technology. Springer International Publishing, Switzerland

Wang Y, Chen W, Shakoor A, Kahraman R, Lu W, Yan B, Gao W (2014) Ni-P-TiO2 composite coatings on copper produced by sol-enhanced electroplating. Int J Electrochem Sci 9(8):4384–4393

Lorenzo-Martin C, Ajayi OO, Hartman K, Bhattacharya S, Yacout A (2019) Effect of Al2O3 coating on fretting wear performance of Zr alloy. Wear 426:219–227

Renondeau H, Taylor RI, Smith GC, Torrance AA (2008) Friction and wear performance of diamond-like carbon and Cr-doped diamond-like carbon coatings in contact with steel surfaces. Proc Inst Mech Eng, Part J: J Eng Tribology 222(3):231–240

Author information

Authors and Affiliations

Contributions

All co-authors have no conflicts of interest to declare that are relevant to the content of this article.

The authors confirm their contribution to the paper as follows: characterization of wear and friction between X160CrMoV12 tool steel and carbon steel sheet during reciprocating sliding tests, for authors Wissal Yangui, Mouna Kallel, Khaled Elleuch, and Noamen Guermazi.

All authors reviewed the results and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yangui, W., Kallel, M., Elleuch, K. et al. Characterization of wear and friction between X160CrMoV12 tool steel and carbon steel sheet during reciprocating sliding tests. Int J Adv Manuf Technol 130, 2475–2488 (2024). https://doi.org/10.1007/s00170-023-12795-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12795-y