Abstract

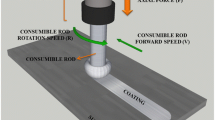

In the present work, the dynamic recrystallization of alloy 316L (austenitic stainless steel) was investigated during friction surfacing, using a machining center with computerized numerical control (CNC). The geometric properties (width and thickness) of the coatings were determined as a function of the rotation speed used in the experiment (1300– 2100 rpm). Therefore, it was possible to estimate the strain rate (\(\dot{\varepsilon}\)) of the process. The strain temperature was evaluated using a thermographic camera (Fluke Ti450). With the strain rate and temperature data, the Zener–Hollomon parameter was determined. The Z value was correlated with the coating microstructure, to understand the relationship between the parameter (Z) and the dynamically recrystallized grain size (dDRX). The results revealed that the sample produced with the rotation speed of 1500 rpm had the highest Z value (9.03 × 1018 [s−1]), the smallest dynamically recrystallized grain size, and the grain size distribution more homogeneous (25.1 ± 4.19 μm), which is in agreement with the literature. Additionally, the Vickers microhardness was evaluated in the longitudinal and transverse directions of the coatings to assess the impact on the mechanical properties. The novelty of this work is that the final grain size could be modelled for the friction surfacing process performed in a conventional CNC machining center, more widely available compared to dedicated equipment, as a function of process parameters.

Similar content being viewed by others

Data availability

Not applicable

References

Sahoo DK, Pradeep AMV, Mohanty BS, Jaswanth A (2020) Influence of inductive heating on coating geometry during deposition of AISI 316 stainless steel over EN8 carbon steel using friction surfacing process. Materials Today: Proceedings. pp 1641–1650. https://doi.org/10.1016/j.matpr.2020.03.545

Gandra J, Krohn H, Miranda M et al (2014) Friction surfacing — a review. J Mater Process Technol 214:1062–1093. https://doi.org/10.1016/j.jmatprotec.2013.12.008

Seidi E, Miller SF, Carlson BE (2021) Friction surfacing deposition by consumable tools. J Manuf Sci Eng 143:120801. https://doi.org/10.1115/1.4050924

Rethnam GSN, Manivel S, Sharma VK et al (2021) Parameter study on friction surfacing of aisi316ti stainless steel over en8 carbon steel and its effect on coating dimensions and bond strength. Materials 14. https://doi.org/10.3390/ma14174967

Guo D, Kwok CT, Chan SLI (2019) Spindle speed in friction surfacing of 316L stainless steel — how it affects the microstructure, hardness and pitting corrosion resistance. Surf Coatings Technol 361:324–341. https://doi.org/10.1016/j.surfcoat.2019.01.055

Stegmueller MJR, Grant RJ, Schindele P (2019) Quantification of the interfacial roughness when coating stainless steel onto aluminium by friction surfacing. Surf Coatings Technol 375:22–33. https://doi.org/10.1016/j.surfcoat.2019.06.060

Nixon RGS, Mohanty BS, Bhaskar GB (2018) Effect of process parameters on physical measurements of AISI316 stainless steel coating on EN24 in friction surfacing. Mater Manuf Process 33:778–785. https://doi.org/10.1080/10426914.2017.1388524

McNelley TR, Swaminathan S, Su JQ (2008) Recrystallization mechanisms during friction stir welding/processing of aluminum alloys. Scr Mater 58:349–354. https://doi.org/10.1016/j.scriptamat.2007.09.064

Kallien Z, Rath L, Roos A, Klusemann B (2020) Experimentally established correlation of friction surfacing process temperature and deposit geometry. Surf Coatings Technol 397:126040. https://doi.org/10.1016/j.surfcoat.2020.126040

Kumar R, Chattopadhyaya S, Ghosh A et al (2017) Characterization of friction surfaced coatings of aisi 316 tool over high-speed-steel substrate. Trans Famena 41:61–76. https://doi.org/10.21278/TOF.41206

Troysi F, Silva K, Dos Santos Í, Brito P (2019) Investigation of austenitic stainless steel coatings on mild steel produced by friction urfacing using a conventional CNC machining center. Mater Res 22. https://doi.org/10.1590/1980-5373-MR-2018-0301

Rollett A, Rohrer GS, Humphreys J (2017) Recrystallization and related annealing phenomena, 3rd edn. Elsevier, Oxford

Das A (2016) Revisiting stacking fault energy of steels. Metall Mater Trans A Phys Metall Mater Sci 47:748–768. https://doi.org/10.1007/s11661-015-3266-9

Nixon RGS, Mohanty BS (2018) Characterization of friction-surfaced SS316 overlaid on medium-carbon steel. Silicon 10:1361–1368. https://doi.org/10.1007/s12633-017-9612-3

Sahoo DK, Mohanty BS, John DF, Pradeep AMV (2020) Multi response optimization and desirability function analysis on friction surfaced deposition of AISI 316 stainless steel over EN8 medium carbon steel. Materials Today: Proceedings. https://doi.org/10.1016/j.matpr.2020.03.131

Puli R, Janaki Ram GD (2012) Dynamic recrystallization in friction surfaced austenitic stainless steel coatings. Mater Charact 74:49–54. https://doi.org/10.1016/j.matchar.2012.09.001

Agiwal H, Yeom H, Ross KA et al (2022) Leak-tight crack repair for 304L stainless steel using friction surfacing. J Manuf Process 79:532–543. https://doi.org/10.1016/j.jmapro.2022.05.004

Sakai T, Belyakov A, Kaibyshev R et al (2014) Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog Mater Sci 60:130–207

Dehghan-Manshadi A, Barnett MR, Hodgson PD (2008) Hot deformation and recrystallization of austenitic stainless steel: Part I. dynamic recrystallization. Metall Mater Trans A Phys Metall Mater Sci 39 A:1359–1370. https://doi.org/10.1007/s11661-008-9512-7

Chang CI, Lee CJ, Huang JC (2004) Relationship between grain size and Zener–Hollomon parameter during friction stir processing in AZ31 Mg alloys. Scr Mater 51:509–514. https://doi.org/10.1016/j.scriptamat.2004.05.043

Zhilyaev AP, Langdon TG (2008) Using high-pressure torsion for metal processing: fundamentals and applications. Prog Mater Sci 53:893–979

Damodaram R, Rai P, Cyril Joseph Daniel S et al (2021) Friction surfacing: a tool for surface crack repair. Surf Coatings Technol 422:127482. https://doi.org/10.1016/j.surfcoat.2021.127482

Huang K, Logé RE (2016) A review of dynamic recrystallization phenomena in metallic materials. Mater Des 111:548–574. https://doi.org/10.1016/j.matdes.2016.09.012

McQueen HJ, Ryan ND (2002) Constitutive analysis in hot working. Mater Sci Eng A 322:43–63. https://doi.org/10.1016/S0921-5093(01)01117-0

George Sahaya Nixon R, Mohanty BS, Sathish R (2018) Friction surfacing of AISI 316 over mild steel: a characteriation study. Def Technol 14:306–312. https://doi.org/10.1016/j.dt.2018.03.003

Vitanov VI, Javaid N, Stephenson DJ (2010) Application of response surface methodology for the optimisation of micro friction surfacing process. Surf Coatings Technol 204. https://doi.org/10.1016/j.surfcoat.2010.04.011

Guo D, Kwok CT, Chan SLI, Tam LM (2021) Friction surfacing of AISI 904L super austenitic stainless steel coatings: microstructure and properties. Surf Coatings Technol 408. https://doi.org/10.1016/j.surfcoat.2020.126811

da Silva MM, Afonso MLB, Silva SLN et al (2018) Application of the friction surfacing process in a CNC machining center: a viability assessment for producing Al-alloy coatings on low carbon steel. J Brazilian Soc Mech Sci Eng 40. https://doi.org/10.1007/s40430-017-0947-x

Silva AP, Martins N, dos Santos IB, Brito P (2022) Dynamic recrystallization in severely plastically deformed iron aluminide coatings obtained by friction surfacing. Manuf Lett 33:15–18. https://doi.org/10.1016/j.mfglet.2022.06.002

Silva KHS, Brito PP, Santos IB et al (2020) The behaviour of AISI 4340 steel coatings on low carbon steel substrate produced by friction surfacing. Surf Coatings Technol 399. https://doi.org/10.1016/j.surfcoat.2020.126170

ASTM International (2010) ASTM E 112-10 Standard Test Methods for Determining Average Grain Size. https://doi.org/10.1520/E0112-10

Rafi HK, Ram GDJ, Phanikumar G, Rao KP (2010) Friction surfaced tool steel (H13) coatings on low carbon steel: a study on the effects of process parameters on coating characteristics and integrity. Surf Coatings Technol 205:232–242. https://doi.org/10.1016/j.surfcoat.2010.06.052

Liu XM, Zou ZD, Zhang YH et al (2008) Transferring mechanism of the coating rod in friction surfacing. Surf Coatings Technol 202:1889–1894. https://doi.org/10.1016/j.surfcoat.2007.08.024

Seidi E, Miller SF (2021) Lateral friction surfacing: experimental and metallurgical analysis of different aluminum alloy depositions. J Mater Res Technol 15. https://doi.org/10.1016/j.jmrt.2021.11.049

Seidi E, Miller SF (2020) A novel approach to friction surfacing: experimental analysis of deposition from radial surface of a consumable tool. Coatings 10:1–17. https://doi.org/10.3390/coatings10111016

Rafi HK, Ram GDJ, Phanikumar G, Rao KP (2011) Microstructural evolution during friction surfacing of tool steel H13. Mater Des 32:82–87. https://doi.org/10.1016/j.matdes.2010.06.031

Galvis JC, Oliveira PHF, Hupalo MF et al (2017) Influence of friction surfacing process parameters to deposit AA6351-T6 over AA5052-H32 using conventional milling machine. J Mater Process Technol 245. https://doi.org/10.1016/j.jmatprotec.2017.02.016

Code availability

Not applicable

Funding

The authors received financial support from the FAPEMIG (Project PPM-00662-18) and the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior — Brasil (CAPES) — Finance Code 001.

Author information

Authors and Affiliations

Contributions

Diego Fonseca Silva: conceptualization, experimental analysis, and writing; Pedro Paiva Brito: conceptualization, supervision, and writing.

Corresponding author

Ethics declarations

Conflict of interest

Not applicable

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Silva, D.F., Brito, P. Influence of rotation speed on microstructure formation during friction surfacing of AISI 316L over mild steel using a conventional CNC machining center. Int J Adv Manuf Technol 126, 4915–4924 (2023). https://doi.org/10.1007/s00170-023-11434-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11434-w