Abstract

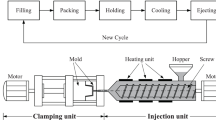

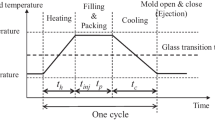

This paper comprehensively reviews the process parameters optimization in plastic injection molding (PIM) using the metamodel-based optimization. The PIM is a typical manufacturing technology to produce lightweight and high gloss appearance plastic products. To produce the plastic product, the process parameters such as melt temperature, injection time, packing pressure, packing time, cooling temperature, and cooling time are conventionally adjusted through the trial-and-error method. Computer-aided engineering (CAE) is one of the alternatives in the PIM but the numerical simulation is computationally so expensive that the metamodel-based optimization is widely used to determine the optimal process parameters. First, typical metamodels including the sampling strategy are briefly reviewed. Then, the papers on the process parameters optimization for high product quality such as warpage, shrinkage, and weldline reduction are reviewed. Rapid heat cycle molding (RHCM) that actively controls the mold temperature is a novel PIM technology, but the process parameters optimization in RHCM is rarely discussed in the literature. Then, the RHCM is also reviewed in this paper. Not only the process parameters optimization but also the cooling channel plays an important role for high product quality and high productivity. Due to the recent advancement of metal 3D printer, it is possible to produce conformal cooling channel. It is possible to enhance the product quality and productivity by using the conformal cooling channel. Several papers on the process parameters using the conformal cooling channel are also reviewed.

Similar content being viewed by others

Availability of data and materials

Not applicable.

Code availability

Not applicable.

References

Fernandes C, Pontes AJ, Viana JC, Gaspar-Cunha A (2018) Modeling and optimization of the injection-molding process: a review. Adv Polym Technol 37:21683. https://doi.org/10.1002/adv.21683

Dang XP (2014) General frameworks for optimization of plastic injection molding process parameters. Simul Model Pract Theory 41:15–27. https://doi.org/10.1016/j.simpat.2013.11.003

do Amaral JVS, Montevechi JAB, Miranda RC, Sousa WT Jr (2022) Metamodel-based simulation optimization: a systematic literature review. Simul Model Pract Theory 114:102403. https://doi.org/10.1016/j.simpat.2021.102403

Zhao NY, Lian JY, Wang PF, Xu ZH (2022) Recent progress in minimizing the warpage and shrinkage deformations by the optimization of process parameters in plastic injection molding: a review. Int J Adv Manuf Technol 120:85–101. https://doi.org/10.1007/s00170-022-08859-0

Mohan M, Ansari M, Shanks RA (2017) Review on the effects of process parameters on strength, shrinkage, and warpage of injection molding plastic component. Polym Plast Technol Eng 56:1–12. https://doi.org/10.1080/03602559.2015.11324

Shayfull Z, Sharif S, Zain AM, Ghazali MF, Saad RM (2014) Potential of conformal cooling channels in rapid heat cycle molding: a review. Adv Polym Technol 33:21381. https://doi.org/10.1002/adv.21381

Wang Y, Yu KM, Wang CCL (2015) Spiral and conformal cooling in plastic injection molding. Comput Aided Des 63:1–15. https://doi.org/10.1016/j.cad.2014.11.012

Wang GG, Shan S (2007) Review of metamodeling techniques in support of engineering design optimization. J Mech Des 129:370–380. https://doi.org/10.1115/1.2429697

Myers RH, Montgomery DC (1995) Response surface methodology. Wiley

Simpson TW, Peplinski JD, Koch PN, Allen JK (2001) Metamodels for computer-based engineering design: survey and recommendations. Eng Comp 17:129–150. https://doi.org/10.1007/PL00007198

Gano SE, Renaud JE, Martin JD, Simpson TW (2006) Update strategies for kriging models used in variable fidelity optimization. Struct Multidiscip Optim 32:287–298. https://doi.org/10.1007/s00158-006-0025-y

Kitayama S, Arakawa M, Yamazaki K (2011) Sequential approximate optimization using radial basis function network for engineering optimization. Optim Eng 12:535–557. https://doi.org/10.1007/s11081-010-9118-y

Cristianini N, Shawe-Taylor J (2000) An introduction to support vector machines and other kernel-based learning methods. Cambridge University Press

Suykens JAK, Vandewalle J (1999) Least squares support vector machine classifiers. Neural Process Lett 9:293–300. https://doi.org/10.1023/A:1018628609742

Kitayama S, Yamazaki K (2011) Simple estimate of the width in Gaussian kernel with adaptive scaling technique. Appl Soft Comput 11:4726–4737. https://doi.org/10.1016/j.asoc.2011.07.011

Andras P (2002) The equivalence of support vector machine and regularization neural networks. Neural Process Lett 65:97–104. https://doi.org/10.1023/A:1015292818897

An W, Sun Y (2006) An equivalence between SILF-SVR and ordinary kriging. Neural Process Lett 23:133–141. https://doi.org/10.1007/s11063-005-4015-7

Kitayama S, Arakawa M, Yamazaki K (2011) Differential evolution as the global optimization technique and its application to structural optimization. Appl Soft Comput 11:3792–3803. https://doi.org/10.1016/j.asoc.2011.02.012

Engelbrecht AP (2005) Fundamentals of computational swarm intelligence. Wiley

Miettinen KM (1998) Nonlinear multiobjective optimization: Kluwer Academic Publisher

Tabatabaei M, Hakanen J, Hartikainen M, Miettinen K, Sindhya K (2015) A survey on handling computationally expensive multiobjective optimization problems using surrogates: non-nature inspired methods. Struct Multidiscip Optim 52:1–25. https://doi.org/10.1007/s00500-017-2965-0

Jones DR, Schonlau G, Welch WJ (1998) Efficient global optimization of expensive black-box functions. J Global Optim 13:455–492. https://doi.org/10.1023/A:1008306431147

Nakayama H, Arakawa M, Sasaki R (2002) Simulation-based optimization using computational intelligence. Optim Eng 3:201–214. https://doi.org/10.1023/A:1020971504868

Kitayama S, Srirat J, Arakawa M, Yamazaki K (2013) Sequential approximate multi-objective optimization using radial basis function network. Struct Multidiscip Optim 48:501–515. https://doi.org/10.1007/s00158-013-0911-z

Kurtaran H, Ozcelik B, Erzurumlu T (2005) Warpage optimization of a bus ceiling lamp base using neural network model and genetic algorithm. J Mater Process Technol 169:314–319. https://doi.org/10.1016/j.jmatprotec.2005.03.013

Kurtaran H, Erzurumlu T (2006) Efficient warpage optimization of thin shell plastic parts using response surface methodology and genetic algorithm. Int J Adv Manuf Technol 27:468–472. https://doi.org/10.1007/s00170-004-2321-2

Yen C, Lin JC, Li W, Huang MF (2006) An abductive neural network approach to the design of runner dimensions for the minimization of warpage in injection mouldings. J Mater Process Technol 174:22–28. https://doi.org/10.1016/j.jmatprotec.2005.02.233

Ozcelik B, Erzurumlu T (2006) Comparison of the warpage optimization in the plastic injection molding using ANOVA, neural network model and genetic algorithm. J Mater Process Technol 171:437–445. https://doi.org/10.1016/j.jmatprotec.2005.04.120

Shen C, Wang L, Li Q (2007) Optimization of injection molding process parameters using combination of artificial neural network and genetic algorithm method. J Mater Process Technol 183:412–418. https://doi.org/10.1016/j.jmatprotec.2006.10.036

Gao Y, Wang X (2008) An effective warpage optimization method in injection molding based on the kriging model. Int J Adv Manuf Technol 37:953–960. https://doi.org/10.1007/s00170-007-1044-6

Deng YM, Zheng D, Lu XJ (2008) Injection moulding optimization of multi-class design variables using a PSO algorithm. Int J Adv Manuf Technol 39:690–698. https://doi.org/10.1007/s00170-007-1258-7

Zhang Y, Deng YM, Sun BS (2009) Injection molding warpage optimization based on a mode-pursuing sampling method. Polym Plast Technol Eng 48:767–774. https://doi.org/10.1080/03602550902824663

Deng YM, Zhang Y, Lam YC (2010) A hybrid of mode-pursuing sampling method and genetic algorithm for minimization of injection molding warpage. Mater Des 31:2118–2123. https://doi.org/10.1016/j.matdes.2009.10.026

Chen CP, Chuang MT, Hsiao YH, Yang YK, Tsai CH (2009) Simulation and experimental study in determining injection molding process parameters for thin-shell plastic parts via design of experiments analysis. Expert Syst Appl 36:10752–10759. https://doi.org/10.1016/j.eswa.2009.02.017

Shi H, Gao Y, Wang X (2010) Optimization of injection molding process parameters using integrated artificial neural network model and expected improvement function method. Int J Adv Manuf Technol 48:955–962. https://doi.org/10.1007/s00170-009-2346-7

Yin F, Mao H, Hua L (2011) A hybrid of back propagation neural network and genetic algorithm for optimization of injection molding process parameters. Mater Des 32:3457–3464. https://doi.org/10.1016/j.matdes.2011.01.058

Yin F, Mao H, Hua L, Guo W, Shu M (2011) Back propagation neural network modeling for warpage prediction and optimization of plastic products during injection molding. Mater Des 32:1844–1850. https://doi.org/10.1016/j.matdes.2010.12.022

Xia W, Luo B, Liao XP (2011) An enhanced optimization approach based on Gaussian process surrogate model for process control in injection molding. Int J Adv Manuf Technol 56:929–942. https://doi.org/10.1007/s00170-011-3227-4

Li Z, Wang X (2013) A black box method for gate location optimization in plastic injection molding. Advanced in Polymer Technology 32:793–808. https://doi.org/10.1002/adv.21322

Park HS, Nguyen TT (2014) Optimization of injection molding process for car fender in consideration of energy efficiency and product quality. J Comput Des Eng 1:256–265. https://doi.org/10.7315/JCDE.2014.025

Chen WC, Nguyen MH, Chiu WH, Chen TN, Tai PH (2016) Optimization of the plastic injection molding process using the Taguchi method, RSM, and hybrid GA-PSO. Int J Adv Manuf Technol 83:1873–1886. https://doi.org/10.1007/s00170-015-7683-0

Zhao J, Cheng G (2016) An innovative surrogate-based searching method for reducing warpage and cycle time in injection molding. Adv Polym Technol 35:21554. https://doi.org/10.1002/adv.21554

Gao Y, Wang X (2009) Surrogate-based process optimization for reducing warpage in injection molding. J Mater Process Technol 209:1302–1309. https://doi.org/10.1016/j.jmatprotec.2008.03.048

Kitayama S, Onuki R, Yamazaki K (2014) Warpage reduction with variable pressure profile in plastic injection molding via sequential approximate optimization. Int J Adv Manuf Technol 72:827–838. https://doi.org/10.1007/s00170-014-5697-7

Kitayama S, Yokoyama M, Takano M, Aiba S (2017) Multi-objective optimization of variable packing pressure profile and process parameters in plastic injection molding for minimizing warpage and cycle time. Int J Adv Manuf Technol 92:3991–3999. https://doi.org/10.1007/s00170-017-0456-1

Feng QQ, Zhou X (2019) Automated and robust multi-objective optimal design of thin-walled product injection process based on hybrid RBF-MOGA. Int J Adv Manuf Technol 101:2217–2231. https://doi.org/10.1007/s00170-018-3084-5

Huang MS (2007) Cavity pressure based grey prediction of the filling-to-packing switchover point for injection molding. J Mater Process Technol 183:419–424. https://doi.org/10.1016/j.jmatprotec.2006.10.037

Nian SC, Fang YC, Huang MS (2019) In-mold and machine sensing and feature extraction for optimized IC-tray manufacturing. Polymers 11:1348. https://doi.org/10.3390/polym11081348

Chen JY, Hung PH, Huang MS (2021) Determination of process parameters based on cavity pressure characteristics to enhance quality uniformity in injection molding. Int J Heat Mass Transf 180:121788. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121788

Zhao P, Zhang J, Dong Z, Huang J, Zhou H, Fu J, Turng LS (2020) Intelligent injection molding on sensing, optimization, and control. Adv Polym Technol 2020:7023616. https://doi.org/10.1155/2020/7023616

Kang GJ, Park CH, Choi DH (2016) Metamodel-based design optimization of injection molding process variables and gates of an automotive glove box for enhancing its quality. J Mech Sci Technol 30:1723–1732. https://doi.org/10.1007/s12206-016-0328-x

Iniesta AA, Cuate A, Schutze O (2019) Multi-objective and many objective design of plastic injection molding process. Int J Adv Manuf Technol 102:3165–3180. https://doi.org/10.1007/s00170-019-03432-8

Kitayama S, Matsubayashi A, Takano M, Yamazaki Y, Kubo Y, Aiba S (2022) Numerical optimization of multi-stage packing pressure profile in plastic injection molding and experimental validation. Polym Adv Technol. https://doi.org/10.1002/pat.5735

Wang X, Gu J, Shen C, Wang X (2015) Warpage optimization with dynamic injection molding technology and sequential optimization method. Int J Adv Manuf Technol 78:177–187. https://doi.org/10.1007/s00170-014-6621-x

Chiang KT, Chang FP (2007) Analysis of shrinkage and warpage in an injection-molded part with a thin shell feature using the response surface methodology. Int J Adv Manuf Technol 35:468–479. https://doi.org/10.1007/s00170-006-0739-4

Zhou J, Turng LS (2007) Process optimization of injection molding using an adaptive surrogate model with Gaussian process approach. Polym Eng Sci 47:684–694. https://doi.org/10.1002/pen.20741

Chen CC, Su PL, Lin YC (2009) Analysis and modeling of effective parameters for dimension shrinkage variation of injection molded part with thin shell feature using response surface methodology. Int J Adv Manuf Technol 45:1087–1095. https://doi.org/10.1007/s00170-009-2045-4

Kurt M, Kaynak Y, Kamber OS, Mutlu B, Bakir B, Koklu U (2010) Influence of molding conditions on the shrinkage and roundness of injection molded parts. Int J Adv Manuf Technol 46:571–578. https://doi.org/10.1007/s00170-009-2149-x

Li C, Wang FL, Chang YQ, Liu Y (2009) A modified global optimization method based on surrogate model and its application in packing pressure profile optimization of injection molding process. Int J Adv Manuf Technol 48:505–511. https://doi.org/10.1007/s00170-009-2302-6

Xu G, Yang ZT, Long GD (2012) Multi-objective optimization of MIMO plastic injection molding process conditions based on particle swarm optimization. Int J Adv Manuf Technol 58:521–531. https://doi.org/10.1007/s00170-011-3425-0

Xu G, Yang Z (2015) Multiobjective optimization of process parameters for plastic injection molding via soft computing and grey correlation analysis. Int J Adv Manuf Technol 78:525–536. https://doi.org/10.1007/s00170-014-6643-4

Cheng J, Liu Z, Tan J (2013) Multiobjective optimization of injection molding parameters based on soft computing and variable complexity method. Int J Adv Manuf Technol 66:907–916. https://doi.org/10.1007/s00170-012-4376-9

Tsai KM, Tang BH (2014) Determination of injection molding process window based on form accuracy of lens using response surface methodology. Int J Adv Manuf Technol 75:947–958. https://doi.org/10.1007/s00170-014-6185-9

Tsai KM, Luo HJ (2015) Comparison of injection molding process windows for plastic lens established by artificial neural network and response surface methodology. Int J Adv Manuf Technol 77:1599–1611. https://doi.org/10.1007/s00170-014-6366-6

Kitayama S, Natsume S (2014) Multi-objective optimization of volume shrinkage and clamping force for plastic injection molding via sequential approximate optimization. Simul Model Pract Theory 48:35–44. https://doi.org/10.1016/j.simpat.2014.07.004

Zhao J, Cheng G, Ruan S, Li Z (2015) Multi-objective optimization design of injection molding process parameters based on the improvement efficient global optimization algorithm and non-dominated sorting-based genetic algorithm. Int J Adv Manuf Technol 78:1813–1826. https://doi.org/10.1007/s00170-014-6770-y

Wu CH, Liang WJ (2005) Effects of geometry and injection-molding parameters on weld-line strength. Polym Eng Sci 45:1021–1030. https://doi.org/10.1002/pen.20369

Li H, Guo Z, Li D (2007) Reducing the effects of weldlines on appearance of plastic products by Taguchi experimental method. Int J Adv Manuf Technol 32:927–931. https://doi.org/10.1007/s00170-006-0411-z

Wu CY, Ku CC, Pai HY (2011) Injection molding optimization with weld line design constraint using distributed multi-population genetic algorithm. Int J Adv Manuf Technol 52:131–141. https://doi.org/10.1007/s00170-010-2719-y

Kim KH, Park JC, Suh YS, Koo BH (2017) Interactive robust optimal design of plastic injection products with minimum weldlines. Int J Adv Manuf Technol 88:1333–1344. https://doi.org/10.1007/s00170-016-8854-3

Kitayama S, Tamada K, Takano M, Aiba S (2018) Numerical and experimental investigation on process parameters optimization in plastic injection molding for weldlines reduction and clamping force minimization. Int J Adv Manuf Technol 97:2087–2098. https://doi.org/10.1007/s00170-018-2021-y

Kitayama S, Hashimoto S, Takano M, Yamazaki Y, Kubo Y, Aiba S (2020) Multi-objective optimization for minimizing weldline and cycle time using variable injection velocity and variable pressure profile in plastic injection molding. Int J Adv Manuf Technol 107:3351–3361. https://doi.org/10.1007/s00170-020-05235-8

Zhou H, Zhang S, Wang Z (2021) Multi-objective optimization of process parameters in plastic injection molding using a differential sensitivity fusion method. Int J Adv Manuf Technol 114:423–449. https://doi.org/10.1007/s00170-021-06762-8

Miettinen K (2014) Survey of methods to visualize alternatives in multiple criteria decision making problems. OR Spectrum 36:3–37. https://doi.org/10.1007/s00291-012-0297-0

Kitayama S, Yamazaki Y, Takano M, Aiba S (2018) Numerical and experimental investigation of process parameters optimization in plastic injection molding using multi-criteria decision making. Simul Model Pract Theory 85:95–105. https://doi.org/10.1016/j.simpat.2018.04.004

Gao H, Zhang Y, Fu Y, Mao T, Zhou M, Li D (2018) Process parameters optimization using a novel classification model for plastic injection molding. Int J Adv Manuf Technol 94:357–370. https://doi.org/10.1007/s00170-017-0812-1

Sacks E, Wylonis E, Allen S, Cima M, Guo H (2000) Production of injection molding tooling with conformal cooling channels using the three dimensional printing process. Polym Eng Sci 40:1232–1247. https://doi.org/10.1002/pen.11251

Xu X, Sachs E, Allen S (2001) The design of conformal cooling channels in injection molding tooling. Polym Eng Sci 41:1265–1279. https://doi.org/10.1002/pen.10827

Ferreira JC, Mateus A (2003) Studies of rapid soft tooling with conformal cooling channels for plastic injection moulding. J Mater Process Technol 142:508–516. https://doi.org/10.1016/S0924-0136(03)00650-2

Dimla DE, Camilotto M, Miani F (2005) Design and optimisation of conformal cooling channels in injection moulding tools. J Mater Process Technol 164–165:1294–1300. https://doi.org/10.1016/j.jmatprotec.2005.02.162

Park HS, Pham NH (2009) Design of conformal cooling channels for an automotive part. Int J Automot Technol 10:87–93. https://doi.org/10.1007/s12239-009-0011-7

Wang Y, Yu KM, Wang CCL, Zhang Y (2011) Automatic design of conformal cooling circuits for rapid tooling. Comput Aided Des 43:1001–1010. https://doi.org/10.1016/j.cad.2011.04.011

Liu S, Wang CCL (2011) Fast intersection-free offset surface generation from freeform models with triangular meshes. IEEE Trans Autom Sci Eng 8:347–360. https://doi.org/10.1109/TASE.2010.2066563

Kuo CC, Jiang ZF, Lee JH (2019) Effects of cooling time of molded parts on rapid injection molds with different layouts and surface roughness of conformal cooling channels. Int J Adv Manuf Technol 103:2169–2182. https://doi.org/10.1007/s00170-019-03694-2

Kuo CC, You ZY (2018) Development of injection molding tooling with conformal cooling channels fabricated by optimal process parameters. Int J Adv Manuf Technol 96:1003–1013. https://doi.org/10.1007/s00170-018-1664-z

Kuo CC, Xu WC (2018) Effects of different cooling channels on the cooling efficiency in the wax injection molding process. Int J Adv Manuf Technol 98:887–895. https://doi.org/10.1007/s00170-018-2345-7

Mercado-Colmenero JM, Martin-Donate C, Rodriguez-Santiago M, Moral-Pulido F, Rubio-Paramio MA (2019) A new conformal cooling lattice design procedure for injection molding applications based on expert algorithms. Int J Adv Manuf Technol 102:1719–1746. https://doi.org/10.1007/s00170-018-03235-3

Li Z, Wang X, Gu J, Ruan S, Shen C, Lyu Y, Zhao Y (2018) Topology optimization for the design of conformal cooling system in thin-wall injection molding based on BEM. Int J Adv Manuf Technol 94:1041–1059. https://doi.org/10.1007/s00170-017-0901-1

Kanbur BB, Suping S, Duan F (2020) Design and optimization of conformal cooling channels for injection molding: a review. Int J Adv Manuf Technol 106:3253–3271. https://doi.org/10.1007/s00170-019-04697-9

Feng S, Kamat AM, Pei Y (2021) Design and fabrication of conformal cooling channels in molds: review and progress updates. Int J Heat Mass Transf 171:121082. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121082

Kuo CC, Jiang ZF, Yang MX, You BJ, Zhong WC (2021) Effects of cooling channel layout on the cooling performance of rapid injection mold. Int J Adv Manuf Technol 114:2697–2710. https://doi.org/10.1007/s00170-021-07033-2

Zhang J, Wang J, Lin J, Guo Q, Chen K, Ma L (2016) Multiobjective optimization of injection molding process parameters based on Opt LHD. EBFNN, and MOPSO, International Journal of Advanced Manufacturing Technology 85:2857–2872. https://doi.org/10.1007/s00170-015-8100-4

Kitayama S, Miyakawa H, Takano M, Aiba S (2017) Multi-objective optimization of injection molding process parameters for short cycle time and warpage reduction using conformal cooling channel. Int J Adv Manuf Technol 88:1735–1744. https://doi.org/10.1007/s00170-016-8904-x

Chen SC, Jong WR, Chang JA (2006) Dynamic mold surface temperature control using induction heating and its effects on the surface appearance of weld line. J Appl Polym Sci 101:1174–1180. https://doi.org/10.1002/app.24070

Wang X, Zhao G, Wang G (2013) Research on the reduction of sink mark and warpage of the molded part in rapid heat cycle molding process. Mater Des 47:779–792. https://doi.org/10.1016/j.matdes.2012.12.047

Wang G, Zhao G, Wang X (2013) Effects of cavity surface temperature on mechanical properties of specimens with and without a weld line in rapid heat cycle molding. Mater Des 46:457–472. https://doi.org/10.1016/j.matdes.2012.10.054

Chen SC, Lin YW, Chien RD, Li HM (2008) Variable mold temperature to improve surface quality of microcellular injection molded parts using induction heating technology. Adv Polym Technol 27:224–232. https://doi.org/10.1002/adv.20133

Chen SC, Peng HS, Chang JA, Jong WR (2004) Simulations and verifications of induction heating on a mold plate. Int Commun Heat Mass Transfer 31:971–980. https://doi.org/10.1016/j.icheatmasstransfer.2004.05.007

Huang MS, Yun JC, Lin YZ (2010) Effect of rapid mold surface inducting heating on the replication ability of microinjection molding light-guided plates with V-grooved microfeatures. J Appl Polym Sci 118:3058–3065. https://doi.org/10.1002/app.32735

Chang PC, Hwang SJ (2006) Simulation of infrared rapid surface heating for injection molding. International Journal of Heat and Mass Trasfer 49:3843–3854. https://doi.org/10.1016/j.ijheatmasstransfer.2006.04.014

Yu MC, Young WB, Hsu PM (2007) Micro-injection molding with the infrared assisted mold heating system. Mater Sci Eng 460–461:288–295. https://doi.org/10.1016/j.msea.2007.02.036

Yao D, Kimerling TE, Kim B (2006) High-frequency proximity heating for injection molding applications. Polym Eng Sci 46:938–945. https://doi.org/10.1002/pen.20548

Chen SC, Chien RD, Lin SH, Lin MC, Chang JA (2009) Feasibility evaluation of gas-assisted heating for mold surface temperature control during injection molding process. Int Commun Heat Mass Transfer 36:806–812. https://doi.org/10.1016/j.icheatmasstransfer.2009.06.007

Jeng MC, Chen SC, Minh PS, Chang JA, Chung CS (2010) Rapid mold temperature control in injection molding by using steam heating. Int Commun Heat Mass Transfer 37:1295–1304. https://doi.org/10.1016/j.icheatmasstransfer.2010.07.012

Wang G, Zhao G, Li H, Guan Y (2011) Multi-objective optimization design of the heating/cooling channels of the steam-heating rapid thermal response mold using particle swarm optimization. Int J Therm Sci 50:790–802. https://doi.org/10.1016/j.ijthermalsci.2011.01.005

Zhao G, Wang G, Guan Y, Li H (2011) Research and application of a new rapid heat cycle molding with electric heating and coolant cooling to improve the surface quality of large LCD TV panels. Polym Adv Technol 22:476–487

Xiao CL, Huang HX, Yang X (2016) Development and application of rapid thermal cycling molding with electric heating for improving surface quality of microcellular injection molded parts. Appl Therm Eng 100:478–489. https://doi.org/10.1016/j.applthermaleng.2016.02.045

Xiao CL, Huang HX (2014) Multiobjective optimization design of heating system in electric heating rapid thermal cycle mold for yielding high gloss parts. J Appl Polym Sci 131:39976. https://doi.org/10.1002/app.39976

Wang G, Zhao G, Guan Y (2012) Thermal response of an electric heating rapid heat cycle molding mold and its effect on surface appearance and tensile strength of the molded part. J Appl Polym Sci 128:1339–1352. https://doi.org/10.1002/app.38274

Wang M, Dong J, Wang W, Zhou J, Dai Z, Zhuang X, Yao X (2013) Optimal design of medium channels for water-assisted rapid thermal cycle mold using multi-objective evolutionary algorithm and multi-attribute decision-making method. Int J Adv Manuf Technol 68:2407–2417. https://doi.org/10.1007/s00170-013-4868-2

Kitayama S, Ishizuki R, Takano M, Kubo Y, Aiba S (2019) Optimization of mold temperature profile and process parameters for weld line reduction and short cycle time in rapid heat cycle molding. Int J Adv Manuf Technol 103:1735–1744. https://doi.org/10.1007/s00170-019-03685-3

Kitayama S, Tsurita S, Takano M, Yamazaki Y, Kubo Y, Aiba S (2022) Multi-objective process parameters optimization in rapid heat cycle molding incorporating variable packing pressure profile for improving weldline, clamping force, and cycle time. Int J Adv Manuf Technol 120:3669–3681. https://doi.org/10.1007/s00170-022-08994-8

Yao D, Chen SC, Kim B (2008) Rapid thermal cycling of injection molds: an overview on technical approaches and applications. Adv Polym Technol 27:233–255. https://doi.org/10.1002/adv.20136

Li XP, Zhao G, Guan Y, Ma MX (2009) Optimal design of heating channels for rapid heat cycle injection mold based on response surface and genetic algorithm. Mater Des 30:4317–4323. https://doi.org/10.1016/j.matdes.2009.04.016

Li XP, Zhao GQ, Guan YJ, Ma MX (2010) Multi-objective optimization of heating channels for rapid heating cycle injection mold using Pareto-based genetic algorithm. Polym Adv Technol 21:669–678. https://doi.org/10.1002/pat.1488

Wang G, Zhao G, Li H, Guan Y (2011) Research on optimization design of the heating/cooling channels for rapid heat cycle molding based on response surface methodology and constrained particle swarm optimization. Expert Syst Appl 38:6705–6718. https://doi.org/10.1016/j.eswa.2010.11.063

Wang G, Zhao G, Guan Y (2011) Research on optimum heating system design for rapid thermal response mold with electric heating based on response surface methodology and particle swarm optimization. J Appl Polym Sci 119:902–921. https://doi.org/10.1002/app.32771

Xiao CL, Huang HX (2014) Optimal design of heating system for rapid thermal cycling mold using particle swarm optimization and finite element method. Appl Therm Eng 64:462–470. https://doi.org/10.1016/j.applthermaleng.2013.12.062

Sasena MJ, Papalambros PY, Goovaerts P (2002) Exploration of metamodeling sampling criteria for constrained global optimization. Eng Optim 34:263–278. https://doi.org/10.1080/03052150211751

Kitayama S, Arakawa M, Yamazaki K (2012) Sequential approximate optimization for discrete design variable problems using radial basis function network. Appl Math Comput 219:4143–4156. https://doi.org/10.1016/j.amc.2012.10.030

Wang L, Shan S, Wang GG (2004) Mode-pursuing sampling method for global optimization on expensive black-box functions. Eng Optim 36:419–438. https://doi.org/10.1080/03052150410001686486

Sharif B, Wang GG, ElMekkawy TY (2008) Mode pursuing sampling method for discrete variable optimization on expensive black-box functions. J Mech Des 130:021402-1-021402–11. https://doi.org/10.1115/1.2803251

Kitayama S, Yamazaki K (2014) Sequential approximate robust design optimization using radial basis function network. Int J Mech Mater Des 10:313–328. https://doi.org/10.1007/s10999-014-9248-z

Funding

This research is partially supported by Grants-in-Aided for Scientific Research from Japan Society for the Promotion of Science (JSPS).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The author declares no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kitayama, S. Process parameters optimization in plastic injection molding using metamodel-based optimization: a comprehensive review. Int J Adv Manuf Technol 121, 7117–7145 (2022). https://doi.org/10.1007/s00170-022-09858-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09858-x