Abstract

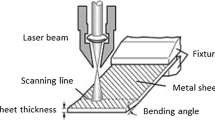

The edge effect is described as an unexpected bending angle variation along the scan line in the laser bending process. In this paper, an analytical model and finite element analysis of temperature fields and bending angles are used to obtain insight into the mechanism of edge effects in the laser bending process of DP980 high-strength steel. Based on the analysis of temperature distributions and influences of scanning velocity on edge effects, it is found that the edge effect of laser bending increases sharply with laser scanning velocity when the constant scanning velocity is smaller than 3 m/min. A varying velocity scanning strategy is proposed to reduce the edge effects of DP980 high-strength steel. By comparing the temperature distributions and bending angles between the varying velocity scanning and the constant one, it is confirmed that the relative bending angle variation in the varying velocity scanning strategy reduces by 54.1% compared to the constant one, which indicates that the varying velocity scanning strategy can significantly reduce the edge effect of the laser bending process. Simultaneously, the average bending angle of the steel sheet increases in the proposed new strategy, which indicates that forming efficiency is improved.

Similar content being viewed by others

Availability of data and materials

All data generated or analyzed during this study are included in this article.

References

Zhang YJ, Kim JB (2015) FEM analysis for laser bending process of DP980 steel sheet. Int J Prec Eng Manuf 16:315–321

Li ZH, Wang XY (2018) Numerical simulation of warping deformation on metal composite plate during laser bending. Inf Las Eng 47(5):115–121

Annamaria G, Mehrshad M, Atabak R, Andrea DB, Massimiliano B (2020) Prediction model for determining the optimum operational parameters in laser forming of fiber-reinforced composites. Adv Manuf 8:242–251

Li L, Yin FX, Nagai K (2011) Process of laminated materials and clad steels production. Mater Sci Forum 675:439–447

Wang XG, Shi YJ, Guo YK, Sun R, Li XF, Zhou XY (2020) Laser curve scanning forming process of laminated metal composite plate. Mater Des 191:1–11

Bao J, Yao YL (2001) Analysis and prediction of edge effects in laser bending. J Manuf Sci Eng 123:53–61

Shi YJ, Shen H (2005) Edge effects of metal plate in laser forming. Trans Nonf Meta Soci China 15:260–263

Hu J, Cao QQ (2010) Experimental study on edge effects in laser bending. J Las Appl 22:144–149

Shen H, Hu J (2010) Analysis and control of edge effects in laser bending. Opti Las Eng 48:305–315

Hu J, Xu HB (2013) Modeling and reducing edge effects in laser bending. J Mater Proc Tech 213:1989–1996

Shi YJ, Zhang C (2016) Study on reducing edge effects by using assistant force in laser forming. J Mater Proc Tech 227:169–177

Wang XG, Shi YJ, Guo YK, Sun R (2020) Laser bending and edge effect control of laminated metal composite plate. Chinese J Las 47(3):1–10

Zhang YJ, Dong WB (2019) Edge effect investigation of DP980 steel sheet in multiple laser scanning process. Int J Prec Eng Manuf 20:319–326

Zhang YJ (2015) A study on laser forming characteristics of high strength steel by finite element analysis. Dissertation, Seoul National University of Science and Technology, Korea

Zhang YJ, Dong WB (2019) Numerical simulation study on laser bending of dual phase high strength steel. J Plas Eng 26:119–124

Funding

This study was supported in part by grants from University Natural Science Research Project of Anhui Province (KJ2020A0071) and Innovation Program for Overseas Returnees in Anhui Province (2018–830246).

Author information

Authors and Affiliations

Contributions

Yajing Zhang contributed to research concept and wrote the article. Wenbin Dong performed the numerical simulations of the study. Tuoyu Yang did the data analysis and interpretation. Chun Guo performed the experiment. Feng Chen contributed to critical revision of the article. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Dong, W., Yang, T. et al. Edge effect reduction in laser bending of DP980 high-strength steel. Int J Adv Manuf Technol 119, 1965–1973 (2022). https://doi.org/10.1007/s00170-021-08424-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08424-1