Abstract

The bending crashworthiness performance of thin-walled structures is affected by several factors such as the end-clamping constraints. The end-clamping configuration should be carefully investigated since it is an important part of the real working condition of a structure under bending loading. End-clamping fixtures (pads) can be used intentionally as complementary energy dissipating mechanisms to trigger new plastic deformation. The present article explores the use of pads to improve the crashworthiness of square tubes under lateral loads. For this purpose, internal, external, and combined pads were located at the profile ends which were subjected to a modified three-point bending test using finite element simulations. The effect of assembly force (fN) and pad length (lp) on the energy absorption was investigated. The structures were made of aluminum 6063-T5 and modeled with elasto-plastic properties considering ductile and shear damage criteria with evolution. Additionally, the numerical results were validated by an experimental three-point bending test on a square profile with constrained and free ends. Our results for a structure with end-clamping fixtures show an improvement of crashworthiness performance in a range from 42.38 – 57.89% relative to a structure with free-ends. The best crush force efficiency (CFE) of 0.78 was obtained when external pads were implemented. Moreover, the importance of fN on the end-clamping pads was noticed since CFE is increased by 9.30% when a normalized force of 0.109 is applied. The importance of pad length was also demonstrated. An improvement of 69.38% in CFE was achieved when a normalized length \( {\overline{L}}_p \)= 0.138 was implemented. Finally, with the findings of our work, a design of end-clamping fixtures for an automobile’s side-door impact beam is presented and analyzed.

Similar content being viewed by others

References

Lai X, Ma C, Hu J, Zhou Q (2012) Impact direction effect on serious-to-fatal injuries among drivers in near-side collisions according to impact location: focus on thoracic injuries. Accid Anal Prev 48:442–450. https://doi.org/10.1016/j.aap.2012.02.023

Marklund P, O, Nilsson L. (2001) Optimization of a car body component subjected to side impact. Struct Multidiscip Optim 21(5):383–392. https://doi.org/10.1007/s001580100117

Ghadianlou A, Abdullah SB (2013) Crashworthiness design of vehicle side door beams under low-speed pole side impacts. Thin-Walled Struct 67:25–33. https://doi.org/10.1016/j.tws.2013.02.004

Tang T, Zhang W, Yin H, Wang H (2016) Crushing analysis of thin-walled beams with various section geometries under lateral impact. Thin-Walled Struct 102:43–57. https://doi.org/10.1016/j.tws.2016.01.017

Song J, Xu S, Liu S, Huang H, Zou M (2020) Design and numerical study on bionic columns with grooves under lateral impact. Thin-Walled Struct 148:106546. https://doi.org/10.1016/j.tws.2019.106546

Saad F, Yusuf ZNM, Latiff ZA, Ismail N (2019) Three point bending analysis on the side impact beam of a Perodua Kancil. In: Advanced Engineering for Processes and Technologies. Springer, Cham, pp 321–327. https://doi.org/10.1007/978-3-030-05621-6_29

Lim TS (2002) Mechanically fastened composite side-door impact beams for passenger cars designed for shear-out failure modes. Compos Struct 56(2):211–221. https://doi.org/10.1016/S0263-8223(02)00005-3

Shin DK, Kim HC, Lee JJ (2014) Numerical analysis of the damage behavior of an aluminum/CFRP hybrid beam under three point bending. Compos Part B 56:397–407. https://doi.org/10.1016/j.compositesb.2013.08.030

Wang Z, Li Z, Zhang X (2016) Bending resistance of thin-walled multi-cell square tubes. Thin-Walled Struct 107:287–299. https://doi.org/10.1016/j.tws.2016.06.017

Huang Z, Zhang X, Zhang H (2018) Energy absorption and optimization design of multi-cell tubes subjected to lateral indentation. Thin-Walled Struct 131:179–191. https://doi.org/10.1016/j.tws.2018.06.020

Santosa S, Wierzbicki T (1999) Effect of an ultralight metal filler on the bending collapse behavior of thin-walled prismatic columns. Int J Mech Sci 41(8):995–1019. https://doi.org/10.1016/S0020-7403(98)00066-6

Shojaeifard MH, Zarei HR, Talebitooti R, Mehdikhanlo M (2012) Bending behavior of empty and foam-filled aluminum tubes with different cross-sections. Acta Mech Solida Sin 25(6):616–626. https://doi.org/10.1016/S0894-9166(12)60057-3

Zhang X, Zhang H (2018) Static and dynamic bending collapse of thin-walled square beams with tube filler. Int J Impact Eng 112:165–179. https://doi.org/10.1016/j.ijimpeng.2017.11.001

Mamalis AG, Manolakos DE, Baldoukas AK, Viegelahn GL (1989) Deformation characteristics of crashworthy thin-walled steel tubes subjected to bending. Proc Inst Mech Eng C Mech Eng Sci 203(6):411–417. https://doi.org/10.1243/PIME_PROC_1989_203_135_02

Miller WS, Zhuang L, Bottema J, Wittebrood A, De Smet P, Haszler A, Vieregge AJMS (2000) Recent development in aluminium alloys for the automotive industry. Mater Sci Eng A 280(1):37–49. https://doi.org/10.1016/S0921-5093(99)00653-X

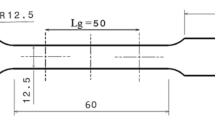

ASTM INT (2004) ASTM E8/E8M - standard test methods for tension testing of metallic materials. ASTM Int (1):1–27

Hibbitt K (2010) Abaqus Analysis User’s Manual, Version 6.10. Sorensen, Inc., Boston, USA

Baykasoglu C, Cetin MT (2015) Energy absorption of circular aluminium tubes with functionally graded thickness under axial impact loading. Int J Crashworthiness 20(1):95–106. https://doi.org/10.1080/13588265.2014.982269

Hooputra H, Gese H, Dell H, Werner H (2004) A comprehensive failure model for crashworthiness simulation of aluminium extrusions. Int J Crashworthiness 9(5):449–464. https://doi.org/10.1533/ijcr.2004.0289

Barsoum I, Khan F, Molki A, Seibi A (2014) Modeling of ductile crack propagation in expanded thin-walled 6063-T5 aluminum tubes. Int J Mech Sci 80:160–168. https://doi.org/10.1016/j.ijmecsci.2014.01.012

Zhu H, Qin C, Wang JQ, Qi FJ (2011) Characterization and simulation of mechanical behavior of 6063 aluminum alloy thin-walled tubes. In: Advanced Materials Research, vol 197-198. Trans Tech Publications Ltd, pp 1500–1508. https://doi.org/10.4028/www.scientific.net/AMR.197-198.1500

Zhang X, Zhang H, Wang Z (2016) Bending collapse of square tubes with variable thickness. Int J Mech Sci 106:107–116. https://doi.org/10.1016/j.ijmecsci.2015.12.006

Safiuddeen T, Balaji P, Dinesh S, ShabeerHussain BM, Giridharan MR (2020) Comparative design and analysis of roll cage for automobiles. Mater Today Proc. https://doi.org/10.1016/j.matpr.2020.06.489

Niknejad A, Elahi SM, Elahi SA, Elahi SA (2013) Theoretical and experimental study on the flattening deformation of the rectangular brazen and aluminum columns. Arch Civ Mech Eng 13:449–464. https://doi.org/10.1016/j.acme.2013.04.008

Pintaude G, Hoechele AR, Cipriano GL (2012) Relation between strain hardening exponent of metals and residual profiles of deep spherical indentation. Mater Sci Technol 28(9-10):1051–1054. https://doi.org/10.1179/1743284711Y.0000000107

Gupta NK, Sekhon GS, Gupta PK (2001) A study of lateral collapse of square and rectangular metallic tubes. Thin-Walled Struct 39(9):745–772. https://doi.org/10.1016/S0263-8231(01)00033-7

Long CR, Yuen STEEVE, Nurick GN (2019) Analysis of a car door subjected to side pole impact. Lat Am J Solids Struct 16(8). https://doi.org/10.1590/1679-78255753

Euro NCAP-2020, https://www.euroncap.com/en/vehicle-safety/the-ratings-explained/adult-occupant-protection/lateral-impact/side-pole/. Accessed 28 January 2021

Center for Collision Safety and Analysis – 2010 Toyota Yaris. https://www.ccsa.gmu.edu/models/2010-toyota-yaris/. Accessed 6 March de 2021

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Conceptualization, formal analysis, and article writing by Quirino Estrada. Numerical simulations and experiments by Julio Vergara-Vazquez. Analysis of numerical simulations by Dariusz Szwedowicz, and review and editing paper by Alejandro Rodriguez-Mendez and Oscar A. Gomez-Vargas. Methodology by Gonzalo Partida-Ochoa. Discussion of results and methodology by Martín Ortiz-Dominguez.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

The authors give permission for the publishing of this article.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Estrada, Q., Vergara-Vázquez, J., Szwedowicz, D. et al. Effect of end-clamping constraints on bending crashworthiness of square profiles. Int J Adv Manuf Technol 116, 3115–3134 (2021). https://doi.org/10.1007/s00170-021-07678-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07678-z