Abstract

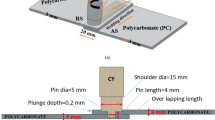

The machining condition monitoring is an important task to improve product quality and avoid economic losses in deep-hole drilling. Out-of-roundness-tolerance is one of major defects in deep-hole drilling process. In this work, the spindle vibration signals generated in deep-hole drilling process are studied to seek the characteristics which can reveal the roundness error change. Considering the influence of background noise on monitoring effect and the sensitivity of high multiple frequency components of spindle vibration signal towards the roundness error change, an improved empirical wavelet de-noising method is proposed to remove the noise of the spindle vibration signal. The high multiple frequency components of the rotation frequency are extracted from the de-noised spindle vibration signal. Firstly, the spindle vibration signal is decomposed by empirical wavelet transform into a set of wavelet coefficients, and then an improved thresholding function is proposed to process the Fourier spectrum of wavelet coefficients for removing the noise from the wavelet coefficients. Secondly, the wavelet coefficients are reconstructed based on the de-noised wavelet coefficients, and the wavelet coefficients which contain high multiple components of rotation frequency are selected. Finally, the energy entropy of the selected wavelet coefficients is calculated as a roundness error monitoring indicator to detect the roundness error of deep hole. The proposed method is verified with well-designed deep-hole drilling tests. The test results show that the monitoring indicator can effectively reflect the roundness error change in deep-hole drilling process.

Similar content being viewed by others

Availability of data and materials

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Matsuzaki K, Ryu T, Sueoka A, Tsukamoto K (2015) Theoretical and experimental study on rifling mark generating phenomena in BTA deep hole drilling process (generating mechanism and countermeasure). Int J Mach Tools Manuf 88:194–205

Aized T, Amjad M (2013) Quality improvement of deep-hole drilling process of AISI D2. Int J Adv Manuf Technol 69:2493–2503

Messaoud A, Weihs C (2009) Monitoring a deep hole drilling process by nonlinear time series modeling. J Sound Vib 321:620–630

Al-Wedyan HM, Bhat RB, Demirli K (2007) Whirling vibrations in boring trepanning association deep hole boring process: analytical and experimental investigations. J Manuf Sci Eng 129:48–62

Deng CS, Chin JH (2004) Roundness errors in BTA drilling and a model of waviness and lobing caused by resonant forced vibrations of its long drill shaft. J Manuf Sci Eng 26:524–534

Kovalyshen, Yevhen (2013) A simple model of bit whirl for deep drilling applications. J Sound Vib 332(24):6321–6334

Xiao W, Zi Y, Chen B, Li B, He Z (2014) A novel approach to machining condition monitoring of deep hole boring. Int J Mach Tool Manu 77:27–33

Uekita M, Takaya Y (2017) Tool condition monitoring technique for deep-hole drilling of large components based on chatter identification in time–frequency domain. Measurement 103:199–207

Biermann D, Bleicher F, Heisel U, Klocke F, Mohring H, Shih AJ (2018) Deep hole drilling. CIRP Ann 67:673–694

Ahmadi K, Altintas Y (2013) Stability of lateral, torsional and axial vibrations in drilling. Int J Mach Tools Manuf 68:63–74

Jiménez A, Arizmendi M, Cumbicus WE (2018) Model for the prediction of low-frequency lateral vibrations in drilling process with pilot hole. Int J Adv Manuf Technol 96:1–20

Huang NE, Shen Z, Long SR, Wu MC, Shih HH, Zheng Q, Yen NC, Tung CC, Liu HH (1998) The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc R Soc Lond Ser A Math Phys Eng Sci 454:903–995

Flandrin P, Rilling G, Goncalves P (2004) Empirical mode decomposition as a filter bank. IEEE Signal Process Lett 11:112–114

Gilles J (2013) Empirical wavelet transform. IEEE Trans Signal Process 61:3999–4010

Si Y, Zhang Z, Kong L, Li S, Wang Q, Kong C, Li Y (2019) Aging condition identification of viscoelastic sandwich structure based on empirical wavelet transform and Hilbert envelope demodulation. Compos Struct 215:13–22

Chen J, Pan J, Li Z, Zi Y, Chen X (2016) Generator bearing fault diagnosis for wind turbine via empirical wavelet transform using measured vibration signals. Renew Energy 89:80–92

Gray RM (2011) Entropy and information theory. Springer Science & Business Media

Wang Z, Du W, Wang J, Zhou J, Han X, Zhang Z, Huang L (2019) Research and application of improved adaptive MOMEDA fault diagnosis method. Measurement 140:63–75

Yuan R, Lv Y, Kong Q, Song G (2019) Percussion-based bolt looseness monitoring using intrinsic multiscale entropy analysis and BP neural network. Smart Mater Struct 28:125001

Garg N, Ryait HS, Kumar A, Bisht A (2018) An effective method to identify various factors for denoising wrist pulse signal using wavelet denoising algorithm. Biomed Mater Eng 29:53–65

Alyasseri ZAA, Khader AT, Al-Betar MA, Awadallah MA (2018) Hybridizing β-hill climbing with wavelet transform for denoising ECG signals. Inf Sci 429:229–246

Bayer FM, Kozakevicius AJ, Cintra RJ (2019) An iterative wavelet threshold for signal denoising. Signal Process 162:10–20

Funding

This research is supported financially by the National Natural Science Foundation of China (Grant No. 51905421) and China Postdoctoral Science Foundation (Grant No. 2019M653880XB) and 2019 Natural Science Project of Shaanxi Provincial Department of Education (19JK0586).

Author information

Authors and Affiliations

Contributions

Yue Si: methodology; investigation; formal analysis; writing, original draft; writing, review and editing. Zhousuo Zhang: conceptualization, methodology. Lingfei Kong: supervision, resources, project administration, funding acquisition. Jianming Zheng: supervision, resources, data curation.

Corresponding author

Ethics declarations

Ethics approval

The article follows the guidelines of the Committee on Publication Ethics (COPE) and involves no studies on human or animal subjects.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Si, Y., Zhang, Z., Kong, L. et al. Condition monitoring of deep-hole drilling process based on improved empirical wavelet de-noising and high multiple frequency components of rotation frequency. Int J Adv Manuf Technol 114, 2201–2214 (2021). https://doi.org/10.1007/s00170-021-06965-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06965-z