Abstract

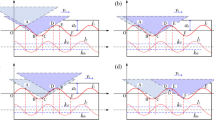

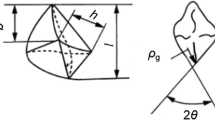

A micromechanics model based on multi-phase modeling was established by using ABAQUS software. The material removal mechanism of SiC particle and the interactions among the cutting tool, SiC particle, Al matrix, and interface were studied, and the simulation results were compared to the experimental results. Different relative positions between the cutting tool and SiC particles can lead to different removal modes of SiC particles, including rolled or penetrated in Al matrix mode, fractured mode, and pulled out mode. Among them, fractured mode can be further divided into partial fractured mode and complete fractured mode. In complete fractured mode and pulled out mode, the SiC particle and its surrounding interface are seriously destroyed. Therefore, in the actual machining process, a small value of cutting depth should be chosen to make the SiC particle removed in rolled or penetrated in Al matrix mode or partial fractured mode for a better structural integrity of SiCp/Al composites. The pit as a result of SiC particle fractured and pulled out from Al matrix is the main defect on the machined surface. With the assistance of ultrasonic vibration, friction coefficient between the cutting tool and workpiece can be decreased. Thus, a better surface integrity of SiCp/Al composites can be obtained. The simulation results agree well with the experimental results.

Similar content being viewed by others

Data availability

The authors confirm that the data and material supporting the findings of this work are available within the article.

References

Ning FD, Cong WL (2020) Ultrasonic vibration-assisted (UV-A) manufacturing processes: state of the art and future perspectives. J Manuf Process 51:174–190. https://doi.org/10.1016/j.jmapro.2020.01.028

Wang JJ, Zhang JF, Feng PF, Guo P (2018) Damage formation and suppression in rotary ultrasonic machining of hard and brittle materials: a critical review. Ceram Int 44(2):1227–1239. https://doi.org/10.1016/j.ceramint.2017.10.050

Liao ZR, Abdelhafeez A, Li HN, Yang Y, Diaz OG, Axinte D (2019) State-of-the-art of surface integrity in machining of metal matrix composites. Int J Mach Tool Manu 143:63–91. https://doi.org/10.1016/j.ijmachtools.2019.05.006

Li JG, Laghari RA (2019) A review on machining and optimization of particle-reinforced metal matrix composites. Int J Adv Manuf Technol 100(9-12):2929–2943. https://doi.org/10.1007/s00170-018-2837-5

Dandekar CR, Shin YC (2012) Modeling of machining of composite materials: a review. Int J Mach Tool Manu 57:102–121. https://doi.org/10.1016/j.ijmachtools.2012.01.006

Zhou L, Huang ST, Zhang CY (2013) Numerical and experimental studies on the temperature field in precision grinding of SiCp/Al composites. Int J Adv Manuf Technol 67(5-8):1007–1014. https://doi.org/10.1007/s00170-012-4543-z

Chen XL, Xie LJ, Xue XG, Wang XB (2017) Research on 3D milling simulation of SiCp/Al composite based on a phenomenological model. Int J Adv Manuf Technol 92(5-8):2715–2723. https://doi.org/10.1007/s00170-017-0315-0

Zhu C, Gu P, Wu Y, Tao Z (2020) Grinding temperature prediction model of high-volume fraction SiCp/Al composite. Int J Adv Manuf Technol 111:1201–1220. https://doi.org/10.1007/s00170-020-06098-9

Monaghan J, Brazil D (1997) Modeling the sub-surface damage associated with the machining of a particle reinforced MMC. Comput Mater Sci 9(1-2):99–107. https://doi.org/10.1016/S0927-0256(97)00063-3

Monaghan J, Brazil D (1998) Modelling the flow processes of a particle reinforced metal matrix composite during machining. Compos A Appl Sci Manuf 29(1-2):87–99. https://doi.org/10.1016/s1359-835×(97)00047-x

El-Gallab MS, Sklad MP (2004) Machining of aluminum/silicon carbide particulate metal matrix composites - part IV. Residual stresses in the machined workpiece. J Mater Process Technol 152(1):23–34. https://doi.org/10.1016/j.jmatprotec.2004.01.061

Zhu Y, Kishawy HA (2005) Influence of alumina particles on the mechanics of machining metal matrix composites. Int J Mach Tool Manu 45(4-5):389–398. https://doi.org/10.1016/j.ijmachtools.2004.09.013

Fathipour M, Hamedi M, Yousefi R (2013) Numerical and experimental analysis of machining of Al (20 vol% SiC) composite by the use of ABAQUS software. Mater Werkst 44(1):14–20. https://doi.org/10.1002/mawe.201300959

Zhou L, Wang Y, Ma ZY, Yu XL (2014) Finite element and experimental studies of the formation mechanism of edge defects during machining of SiCp/Al composites. Int J Mach Tool Manu 84:9–16. https://doi.org/10.1016/j.ijmachtools.2014.03.003

Lasko G, Weber U, Schmauder S (2014) Finite element simulations of crack propagation in Al2O3/6061Al composites. Acta Metall Sin Eng 27(5):853–861. https://doi.org/10.1007/s40195-014-0124-5

Zhou L, Cui C, Zhang PF, Ma ZY (2017) Finite element and experimental analysis of machinability during machining of high-volume fraction SiCp/Al composites. Int J Adv Manuf Technol 91(5-8):1935–1944. https://doi.org/10.1007/s00170-016-9933-1

Ramesh MV, Chan KC, Lee WB, Cheung CF (2001) Finite-element analysis of diamond turning of aluminium matrix composites. Compos Sci Technol 61(10):1449–1456. https://doi.org/10.1016/S0266-3538(01)00047-1

Pramanik A, Zhang LC, Arsecularatne JA (2007) An FEM investigation into the behavior of metal matrix composites: tool–particle interaction during orthogonal cutting. Int J Mach Tool Manu 47(10):1497–1506. https://doi.org/10.1016/j.ijmachtools.2006.12.004

Zhou L, Huang ST, Wang D, Yu XL (2011) Finite element and experimental studies of the cutting process of SiCp/Al composites with PCD tools. Int J Adv Manuf Technol 52(5-8):619–626. https://doi.org/10.1007/s00170-010-2776-2

Pramanik A, Zhang LC (2017) Particle fracture and debonding during orthogonal machining of metal matrix composites. Adv Manuf 5(1):77–82. https://doi.org/10.1007/s40436-017-0170-0

Wu Q, Xu WX, Zhang LC (2018) A micromechanics analysis of the material removal mechanisms in the cutting of ceramic particle reinforced metal matrix composites. Mach Sci Technol 22(4):638–651. https://doi.org/10.1080/10910344.2017.1382516

Wang YF, Liao WH, Yang K, Teng XY, Chen WQ (2019) Simulation and experimental investigation on the cutting mechanism and surface generation in machining SiCp/Al MMCs. Int J Adv Manuf Technol 100(5-8):1393–1404. https://doi.org/10.1007/s00170-018-2769-0

Yin GQ, Gong YD, Li YW, Song JL, Zhou YG (2019) Modeling and evaluation in grinding of SiCp/Al composites with single diamond grain. Int J Mech Sci 163. https://doi.org/10.1016/j.ijmecsci.2019.105137

Duan CZ, Sun W, Fu C, Zhang FY (2018) Modeling and simulation of tool-chip interface friction in cutting Al/SiCp composites based on a three-phase friction model. Int J Mech Sci 142:384–396. https://doi.org/10.1016/j.ijmecsci.2018.05.014

Wang T, Xie LJ, Wang XB (2015) Simulation study on defect formation mechanism of the machined surface in milling of high volume fraction SiCp/Al composite. Int J Adv Manuf Technol 79(5-8):1185–1194. https://doi.org/10.1007/s00170-015-6876-x

Wang BB, Xie LJ, Chen XL, Wang XB (2016) The milling simulation and experimental research on high volume fraction of SiCp/Al. Int J Adv Manuf Technol 82(5-8):809–816. https://doi.org/10.1007/s00170-015-7399-1

Teng XY, Chen WQ, Huo DH, Shyha I, Lin C (2018) Comparison of cutting mechanism when machining micro and nano-particles reinforced SiC/Al metal matrix composites. Compos Struct 203:636–647. https://doi.org/10.1016/j.compstruct.2018.07.076

Du JG, Zhang HZ, He WB, Ma J, Ming WY, Cao Y (2019) Simulation and experimental study on surface formation mechanism in machining of SiCp/Al composites. Appl Compos Mater 26(1):29–40. https://doi.org/10.1007/s10443-018-9681-5

Liu JW, Cheng K, Ding H, Chen SJ, Zhao L (2018) Simulation study of the influence of cutting speed and tool-particle interaction location on surface formation mechanism in micromachining SiCp/Al composites. Proc Inst Mech Eng C J Eng Mech Eng Sci 232(11):2044–2056. https://doi.org/10.1177/0954406217713521

Xiang DH, Shi ZL, Feng HR, Wu BF, Zhang ZM, Chen YB, Niu XX, Zhao B (2019) Finite element analysis of ultrasonic assisted milling of SiCp/Al composites. Int J Adv Manuf Technol 105(7-8):3477–3488. https://doi.org/10.1007/s00170-019-04542-z

Dandekar CR, Shin YC (2011) Molecular dynamics based cohesive zone law for describing Al–SiC interface mechanics. Compos A Appl Sci Manuf 42(4):355–363. https://doi.org/10.1016/j.compositesa.2010.12.005

Umer U, Ashfaq M, Qudeiri JA, Hussein HMA, Danish SN, Al-Ahmari AR (2015) Modeling machining of particle-reinforced aluminum-based metal matrix composites using cohesive zone elements. Int J Adv Manuf Technol 78(5-8):1171–1179. https://doi.org/10.1007/s00170-014-6715-5

Ghandehariun A, Kishawy HA, Umer U, Hussein HM (2016) Analysis of tool-particle interactions during cutting process of metal matrix composites. Int J Adv Manuf Technol 82(1-4):143–152. https://doi.org/10.1007/s00170-015-7346-1

Ghandehariun A, Kishawy HA, Umer U, Hussein HM (2016) On tool-workpiece interactions during machining metal matrix composites: investigation of the effect of cutting speed. Int J Adv Manuf Technol 84(9-12):2423–2435. https://doi.org/10.1007/s00170-015-7869-5

Ghandehariun A, Nazzal M, Kishawy HA, Umer U (2017) On modeling the deformations and tool-workpiece interactions during machining metal matrix composites. Int J Adv Manuf Technol 91(5-8):1507–1516. https://doi.org/10.1007/s00170-016-9776-9

Ghandehariun A, Kishawy H, Balazinski M (2016) On machining modeling of metal matrix composites: a novel comprehensive constitutive equation. Int J Mech Sci 107:235–241. https://doi.org/10.1016/j.ijmecsci.2016.01.020

Nasr MNA, Ghandehariun A, Kishawy HA (2016) A physics-based model for metal matrix composites deformation during machining: a modified constitutive equation. J Eng Mater Trans ASME 139(1):011003–011003. https://doi.org/10.1115/1.4034509

Umer U, Kishawy H, Ghandehariun A, Xie LJ, Al-Ahmari A (2017) On modeling tool performance while machining aluminum-based metal matrix composites. Int J Adv Manuf Technol 92(9-12):3519–3530. https://doi.org/10.1007/s00170-017-0368-0

Wu Q, Xu WX, Zhang LC (2019) Machining of particulate-reinforced metal matrix composites: an investigation into the chip formation and subsurface damage. J Mater Process Technol:274. https://doi.org/10.1016/j.jmatprotec.2019.116315

Wu Q, Xu WX, Zhang LC (2019) Microstructure-based modelling of fracture of particulate reinforced metal matrix composites. Compos B Eng 163:384–392. https://doi.org/10.1016/j.compositesb.2018.12.099

Zhao X, Gong YD, Cai M, Han B (2020) Numerical and experimental analysis of material removal and surface defect mechanism in scratch tests of high volume fraction SiCp/Al composites. Materials 13(3):25. https://doi.org/10.3390/ma13030796

Dandekar CR, Shin YC (2009) Multi-step 3-D finite element modeling of subsurface damage in machining particulate reinforced metal matrix composites. Compos A Appl Sci Manuf 40(8):1231–1239. https://doi.org/10.1016/j.compositesa.2009.05.017

Dandekar CR, Shin YC (2013) Multi-scale modeling to predict sub-surface damage applied to laser-assisted machining of a particulate reinforced metal matrix composite. J Mater Process Technol 213(2):153–160. https://doi.org/10.1016/j.jmatprotec.2012.09.010

Zheng W, Zhou M, Zhou L (2017) Influence of process parameters on surface topography in ultrasonic vibration- assisted end grinding of SiCp/Al composites. Int J Adv Manuf Technol 91(5-8):2347–2358. https://doi.org/10.1007/s00170-016-9931-3

Zheng W, Wang YJ, Zhou M, Wang Q, Ling L (2018) Material deformation and removal mechanism of SiCp/Al composites in ultrasonic vibration assisted scratch test. Ceram Int 44(13):15133–15144. https://doi.org/10.1016/j.ceramint.2018.05.150

Zhang H, Ramesh K, Chin E (2005) Effects of interfacial debonding on the rate-dependent response of metal matrix composites. Acta Mater 53(17):4687–4700. https://doi.org/10.1016/j.actamat.2005.07.004

Ozel T (2006) The influence of friction models on finite element simulations of machining. Int J Mach Tool Manu 46(5):518–530. https://doi.org/10.1016/j.ijmachtools.2005.07.001

Subhash G, Zhang W (2002) Investigation of the overall friction coefficient in single-pass scratch test. Wear 252(1-2):123–134. https://doi.org/10.1016/s0043-1648(01)00852-3

Zhou M, Zheng W (2016) A model for grinding forces prediction in ultrasonic vibration assisted grinding of SiCp/Al composites. Int J Adv Manuf Technol 87(9-12):3211–3224. https://doi.org/10.1007/s00170-016-8726-x

Pittari J, Subhash G, Zheng J, Halls V, Jannotti P (2015) The rate-dependent fracture toughness of silicon carbide- and boron carbide-based ceramics. J Eur Ceram Soc 35(16):4411–4422. https://doi.org/10.1016/j.jeurceramsoc.2015.08.027

Dabade UA, Dapkekar D, Joshi SS (2009) Modeling of chip-tool interface friction to predict cutting forces in machining of Al/SiCp composites. Int J Mach Tool Manu 49(9):690–700. https://doi.org/10.1016/j.ijmachtools.2009.03.003

Sikder S, Kishawy HA (2012) Analytical model for force prediction when machining metal matrix composite. Int J Mech Sci 59(1):95–103. https://doi.org/10.1016/j.ijmecsci.2012.03.010

Venkatachalam S, Liang SY (2007) Effects of ploughing forces and friction coefficient in microscale machining. J Manuf Sci Eng Trans ASME 129(2):274–280. https://doi.org/10.1115/1.2673449

Funding

This work is funded by the National Natural Science Foundation of China (51905138), China Postdoctoral Science Foundation (BX20190048), and the Natural Science Foundation of Tianjin City (19JCYBJC18900).

Author information

Authors and Affiliations

Contributions

Wei Zheng: simulation modeling, software, writing (original draft preparation), reviewing, and editing. Da Qu: software, writing (reviewing and editing). Guochao Qiao: experimental work, writing (reviewing and editing)

Corresponding authors

Ethics declarations

Ethical approval

The article follows the guidelines of the Committee on Publication Ethics (COPE) and involves no studies on human or animal subjects.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zheng, W., Qu, D. & Qiao, G. Multi-phase modeling of SiC particle removal mechanism in ultrasonic vibration–assisted scratching of SiCp/Al composites. Int J Adv Manuf Technol 113, 535–551 (2021). https://doi.org/10.1007/s00170-021-06675-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06675-6