Abstract

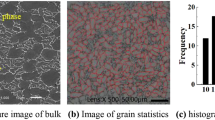

High-speed cutting (HSC) and ultra-high-speed cutting (u-HSC) (6.07–32.7 m/s) tests of Ti-6Al-4V alloy were developed based on an improved Split Hopkinson Pressure Bars (SHPB) system. Specific cutting energy was calculated and scaling effect was observed in HSC with different uncut chip thicknesses (20–200 μm). Considering time-dependent (in situ and ex situ) microstructure and mechanical parameters, chip morphology, adiabatic shear band (ASB), chip-free surface, material separation characteristic at chip-workpiece interface, and surface integrity were investigated. The micro-hardness within ASB was 25% higher than that outside of the ASB. Ultra-fine grains (77% grain sizes less than 330 nm) and micro-texture were observed by electron backscattering diffraction (EBSD) test. Grain refinement in ASB was explained by rotation dynamic recrystallization. The maximum shear strain and the range of shear strain rate in ASB at the condition of v = 10 m/s and t1 = 100 μm were approximately 17 and 6.44 × 106 s−1–8.5 × 106 s−1, respectively. Severe plastic deformation was observed by the dimples at ductile fracture surface along ASB. Mechanism of parabolic and ellipsoid dimples caused by shear and tensile stresses was explained for HSC of Ti-6Al-4V alloy. Additionally, the micro-hardness of machined subsurface and the ASB (ex situ parameter) exhibits a relationship with specific energy (in situ parameter), which can provide an effective way to control the formation of ASB and surface integrity by the control of in situ parameters in HSC and u-HSC conditions.

Similar content being viewed by others

Data availability

The data presented and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Myers JR, Bomberger HB, Froes FH (2013) Corrosion behavior and use of titanium and its alloys. JOM 36(10):50–60

Van Kann H (1982) Titanium and titanium alloys. Plenum Press, NY, USA

Wood RAFR (1972) Titanium alloys handbook. Air Force Materials Laboratory, Wright-Patterson Air Force Base, OH, USA

Abukhshim NA, Mativenga PT, Sheikh MA (2006) Heat generation and temperature prediction in metal cutting: a review and implications for high speed machining. Int J Mach Tools Manuf 46(7):782–800

Umbrello D (2007) Finite element simulation of conventional and high speed machining of Ti6Al4V alloy. J Mater Process Technol 196(1):79–87

Che Haron CH, Jawaid A (2005) The effect of machining on surface integrity of titanium alloy Ti–6%Al–4%V. J Mater Process Technol 166(2):188–192

Salomon C (1931) Verfahren zur bearbeitung von metallen oder bei einer bearbeitung durch schneidende werkzeuge sich ahnlich verhaltenden werkstoffen. Deutsches patent 523594:931

Jiang MQ, Dai LH, Ye GG, Tong XH (2013) Modeling periodic adiabatic shear band evolution during high speed machining Ti-6Al-4V alloy. Int J Plast 40(1):39–55

Wang B, Liu Z (2014) Investigations on the chip formation mechanism and shear localization sensitivity of high-speed machining Ti6Al4V. Int J Adv Manuf Technol 75(5–8):1065–1076

Wang B, Liu Z (2015) Shear localization sensitivity analysis for Johnson--Cook constitutive parameters on serrated chips in high speed machining of Ti6Al4V. Simul Model Pract Theory 55:63–76

Ye GG, Chen Y, Xue SF, Dai LH (2014) Critical cutting speed for onset of serrated chip flow in high speed machining. Int J Mach Tools Manuf 86:18–33

Li G, Cai Y, Qi H (2018) Prediction of the critical cutting conditions of serrated chip in high speed machining based on linear stability analysis. Int J Adv Manuf Technol 94(1–4):1119–1129

Chen G, Ren C, Yang X, Guo T (2011) Evidence of thermoplastic instability about segmented chip formation process for Ti--6Al--4V alloy based on the finite-element method. Proc Inst Mech Eng C J Mech Eng Sci 225(6):1407–1417

Hou ZB, Komanduri R (1997) Modeling of thermomechanical shear instability in machining. Int J Mech Sci 39(11):1273–1314

Wang B, Liu Z (2016) Evaluation on fracture locus of serrated chip generation with stress triaxiality in high speed machining of Ti6Al4V. Mater Des 98:68–78

Sagapuram D, Viswanathan K, Mahato A, Sundaram NK, M’Saoubi R, Trumble KP, Chandrasekar S (2016) Geometric flow control of shear bands by suppression of viscous sliding. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences 472(2192):20160167

Xu X, Zhang J, Liu H, He Y, Zhao W (2019) Grain refinement mechanism under high strain-rate deformation in machined surface during high speed machining Ti6Al4V. Mater Sci Eng A 752:167–179

Wang B, Liu Z, Song Q, Wan Y, Shi Z (2016) Proper selection of cutting parameters and cutting tool angle to lower the specific cutting energy during high speed machining of 7050-T7451 aluminum alloy. J Clean Prod 129:292–304

Warsi SS, Jaffery SHI, Ahmad R, Khan M, Agha MH, Ali L (2018) Development and analysis of energy consumption map for high-speed machining of Al 6061-T6 alloy. Int J Adv Manuf Technol 96(1–4):91–102

Liu K (2005) Process modeling of micro-cutting including strain gradient effects. Dissertation, Georgia institute of technology

Subbiah S, Melkote SN (2007) Evidence of ductile tearing ahead of the cutting tool and modeling the energy consumed in material separation in micro-cutting. J Eng Mater Technol 129(2):321–331

Fu X, Lin W, Pan Y, Liu W (2018) Morphology evolution and micro-mechanism of chip formation during high-speed machining. Int J Adv Manuf Technol 98(1–4):165–175

Subbiah S, Melkote SN (2008) Effect of finite edge radius on ductile fracture ahead of the cutting tool edge in micro-cutting of Al2024-T3. Mater Sci Eng A 474(1–2):283–300

Gente A, Hoffmeister H-W, Evans CJ (2001) Chip formation in machining Ti6Al4V at extremely high cutting speeds. CIRP Ann 50(1):49–52

Sutter G, List G (2013) Very high speed cutting of Ti-6Al-4V titanium alloy change in morphology and mechanism of chip formation. Int J Mach Tools Manuf 66:37–43

Ye GG, Xue SF, Ma W, Jiang MQ, Ling Z, Tong XH, Dai LH (2012) Cutting AISI 1045 steel at very high speeds. Int J Mach Tools Manuf 56:1–9

Ye GG, Xue SF, Ma W, Dai LH (2016) Onset and evolution of discontinuously segmented chip flow in ultra-high-speed cutting Ti-6Al-4V. Int J Adv Manuf Technol 88(1–4):1161–1174

Ma W, Li X, Dai L, Ling Z (2012) Instability criterion of materials in combined stress states and its application to orthogonal cutting process. Int J Plast 30:18–40

Molinari A, Musquar C, Sutter G (2002) Adiabatic shear banding in high speed machining of Ti-6Al-4V: experiments and modeling. Int J Plast 18(4):443–459

Chen G, Ren C, Qin X, Li J (2015) Temperature dependent work hardening in Ti-6Al-4V alloy over large temperature and strain rate ranges: experiments and constitutive modeling. Mater Des 83:598–610

Chen G, Lu L, Ren C, Ge X (2018) Temperature dependent negative to positive strain rate sensitivity and compression behavior for 2024-T351 aluminum alloy. J Alloys Compd 765:569–585

Pawade RS, Sonawane HA, Joshi SS (2009) An analytical model to predict specific shear energy in high-speed turning of Inconel 718. Int J Mach Tools Manuf 49(12–13):979–990

Kopalinsky EM, Oxley PLB (1984) Size effects in metal removal processes. Mechanical Properties at High Rates of Strain 1984:389–396

Peirs J, Tirry W, Amin-Ahmadi B, Coghe F, Verleysen P, Rabet L, Schryvers D, Degrieck J (2013) Microstructure of adiabatic shear bands in Ti6Al4V. Mater Charact 75:79–92

Chen G, Ren C, Lu L, Ke Z, Qin X, Ge X (2018) Determination of ductile damage behaviors of high strain rate compression deformation for Ti-6Al-4V alloy using experimental-numerical combined approach. Eng Fract Mech 200:499–520

Chen G, Ren C, Yang X, Jin X, Guo T (2011) Finite element simulation of high-speed machining of titanium alloy (Ti–6Al–4V) based on ductile failure model. Int J Adv Manuf Technol 56(9–12):1027–1038

Sun S, Brandt M, Dargusch MS (2009) Characteristics of cutting forces and chip formation in machining of titanium alloys. Int J Mach Tools Manuf 49(7–8):561–568

Meyers MA, Subhash G, Kad BK, Prasad L (1994) Evolution of microstructure and shear-band formation in α-hcp titanium. Mech Mater 17(2–3):175–193

Hughes GD, Smith SD, Pande CS, Johnson HR, Armstrong RW (1986) Hall-Petch strengthening for the microhardness of twelve nanometer grain diameter electrodeposited nickel. Scr Metall 20(1):93–97

Lins JFC, Sandim HRZ, Kestenbach HJ, Raabe D, Vecchio KS (2007) A microstructural investigation of adiabatic shear bands in an interstitial free steel. Mater Sci Eng A 457(1–2):205–218

Sun K, Yu X, Tan C, Ma H, Wang F, Cai H (2014) Effect of microstructure on adiabatic shear band bifurcation in Ti--6Al--4V alloys under ballistic impact. Mater Sci Eng A 595:247–256

Nesterenko VF, Meyers MA, LaSalvia JC, Bondar MP, Chen YJ, Lukyanov YL (1997) Shear localization and recrystallization in high-strain, high-strain-rate deformation of tantalum. Mater Sci Eng A 229(1–2):23–41

Li Z, Wang B, Zhao S, Valiev RZ, Vecchio KS, Meyers MA (2017) Dynamic deformation and failure of ultrafine-grained titanium. Acta Mater 125:210–218

Joshi S, Tewari A, Joshi SS (2015) Microstructural characterization of chip segmentation under different machining environments in orthogonal machining of Ti6Al4V. J Eng Mater Technol 137(1):011005

Dodd B, Bai Y (1989) Width of adiabatic shear bands formed under combined stresses. Mater Sci Technol 5(6):557–559

Chen G, Lu L, Ke Z, Qin X, Ren C (2019) Influence of constitutive models on finite element simulation of chip formation in orthogonal cutting of Ti-6Al-4V alloy. Procedia Manufacturing 33:530–537

Liao SC, Duffy J (1998) Adiabatic shear bands in a Ti-6Al-4V titanium alloy. Journal of the Mechanics and Physics of Solids 46(11):2201–2231

Handbook M (1998) Metallic materials and elements for aerospace vehicle structures. Military Handbook No. MIL-HDBK-5H, Section, 5

Derby B (1991) The dependence of grain size on stress during dynamic recrystallisation. Acta Metall Mater 39(5):955–962

Hasnaoui A, Van Swygenhoven H, Derlet PM (2003) Dimples on nanocrystalline fracture surfaces as evidence for shear plane formation. Science 300(5625):1550–1552

Cho K, Chi YC, Duffy J (1990) Microscopic observations of adiabatic shear bands in three different steels. Metall Trans A 21(5):1161–1175

Liu H, Zhang J, Xu X, Zhao W (2018) Experimental study on fracture mechanism transformation in chip segmentation of Ti-6Al-4V alloys during high-speed machining. J Mater Process Technol 257:132–140

Xu Y, Zhang J, Bai Y, Meyers MA (2008) Shear localization in dynamic deformation: microstructural evolution. Metall Mater Trans A 39(4):811–843

Ashby MF, Verrall RA (1973) Diffusion-accommodated flow and superplasticity. Acta Metall 21(2):149–163

Denkena B, Biermann D (2014) Cutting edge geometries. CIRP Ann 63(2):631–653

Chen G, Chen S, Caudill J, Jawahir IS (2019) Effect of cutting edge radius and cooling strategies on surface integrity in orthogonal machining of Ti-6Al-4V alloy. Procedia CIRP 82:148–153

Acknowledgements

The authors would like to thank Dr. Shuai Chen from Nano Analysis Department, Oxford Instruments Technology (Shanghai) Co., Ltd. for his help with the EBSD tests.

Funding

This work was supported by the Natural Science Foundation of China (No. 51575384) and the Natural Science Foundation of Tianjin (No. 16JCQNJC04600).

Author information

Authors and Affiliations

Contributions

Conceptualization: Guang Chen; data curation: Jiaying Ge and Lianpeng Lu; formal analysis: Jian Liu and Chengzu Ren; funding acquisition: Guang Chen; investigation: Guang Chen, Jiaying Ge, Lianpeng Lu, and Jian Liu; methodology: Guang Chen, Jiaying Ge, and Lianpeng Lu; supervision: Guang Chen and Chengzu Ren; writing—original draft preparation: Guang Chen, Jiaying Ge, and Lianpeng Lu; writing—review and editing: Jian Liu and Chengzu Ren.

Corresponding author

Ethics declarations

Ethical approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no conflicts of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, G., Ge, J., Lu, L. et al. Mechanism of ultra-high-speed cutting of Ti-6Al-4V alloy considering time-dependent microstructure and mechanical behaviors. Int J Adv Manuf Technol 113, 193–213 (2021). https://doi.org/10.1007/s00170-021-06589-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06589-3