Abstract

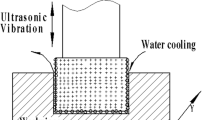

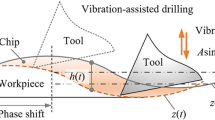

The ability to form regular chips and evacuate them smoothly is crucial for deep hole drilling. In this work, an eccentric cam mechanism is used to apply low-frequency axial vibration at the end of the drill tube for boring and trepanning association (BTA) deep hole machining, and the instantaneous cutting thickness equation of low-frequency axial vibration assisted drilling is derived, which can actively control the length of the chip and achieve a good chip removal effect. Considering the variable geometric parameters and the scale effect of teeth cutting, a new analytical model is established to obtain the instantaneous drilling force of staggered teeth BTA deep hole drill assisted by low-frequency axial vibration. The relevant parameters in drilling force model are identified, and the distribution laws of the normal friction angle, normal shear angle, and shear stress with instantaneous cutting layer thickness and drilling radius values are achieved. The influence of the vibration drilling process parameters, including feed, speed, amplitude, and frequency ratio, on the drilling force is investigated experimentally, and the validity of the drilling force model is verified. These results show that the drilling force model is reliable, and the thrust and torque of the low-frequency axial vibration assisted drilling relative to ordinary drilling are reduced by 21.63% and 13.74%, respectively.

Similar content being viewed by others

References

Yang SC, Tong X, Ma XQ, Ji W, Liu XL, Zhang YH (2018) The guide block structure design of boring and trepanning association (BTA) deep hole drilling[J]. Int J Adv Manuf Technol 99:911–918. https://doi.org/10.1007/s00170-018-2418-7

Biermann D, Bleicher F, Heisel U, Klocke F, Möhring HC, Shih A (2018) Deep hole drilling [J]. CIRP Ann Manuf Technol 67:673–694. https://doi.org/10.1016/j.cirp.2018.05.007

Hyo IA, Sang HJ, Hyun HC, Hae WL (2019) Ductility-dip cracking susceptibility of Inconel 690 using Nb content [J]. J Alloys Compd 783:263–271. https://doi.org/10.1016/j.jallcom.2018.12.208

Li J, Lu YH, Xin L, Shoji T (2018) The subsurface damage mechanism of Inconel 690 during fretting wear in pure water [J]. Tribol Int 117:152–161. https://doi.org/10.1016/j.triboint.2017.08.024

Astakhov VP, Galitsky VV, Osman MOM (1995) A novel approach to the design of self-piloting drills with external chip removal, part 1: geometry of the cutting tip and grinding process [J]. J Manuf Sci Eng 117(4):453–463. https://doi.org/10.1115/1.2803521

Biermann D, Kirschner M, Eberhardt D (2014) A novel method for chip formation analyses in deep hole drilling with small diameters [J]. Prod Eng 8:491–497. https://doi.org/10.1007/s11740-014-0566-7

Woon KS, Tnay GL, Rahman M, Wan S, Yeo SH (2017) A computational fluid dynamics (CFD) model for effective coolant application in deep hole gundrilling [J]. Int J Mach Tools Manuf 113:10–18. https://doi.org/10.1016/j.ijmachtools.2016.11.008

Kirschner M, Michel S, Berger S, Biermann D, Debus J, Braukmann D, Bayer M (2018) In situ chip formation analyses in micro single-lip and twist deep hole drilling [J]. Int J Adv Manuf Technol 95:2315–2324. https://doi.org/10.1007/s00170-017-1339-1

Fu ZT, Zhang XM, Wang XL, Yang WY (2014) Analytical modeling of chatter vibration in orthogonal cutting usinga predictive force model [J]. Int J Mech Sci 88:145–153. https://doi.org/10.1016/j.ijmecsci.2014.08.005

Wang YG, Yan XP, Li B, Tu GC (2012) The study on the chip formation and wear behavior for drilling forged steel S48CS1V with TiAlN-coated gun drill [J]. Int J Refract Met Hard Mater 30:200–207. https://doi.org/10.1016/j.ijrmhm.2011.08.010

Zhang XQ, Tnay GL, Liu K, Kumar AS (2018) Effect of apex offset inconsistency on hole straightness deviation in deep hole gun drilling of Inconel 718 [J]. Int J Mach Tools Manuf 125:123–132. https://doi.org/10.1016/j.ijmachtools.2017.11.011

Kong LF, Li Y, Lu YJ, Li DX (2009) Complex nonlinear behaviors of drilling shaft system in boring and trepanning association deep hole drilling [J]. Int J Adv Manuf Technol 45:211–218. https://doi.org/10.1007/s00170-009-1961-7

Kong LF, Chin JH, Li Y, Lu YJ, Li PY (2014) Targeted suppression of vibration in deep hole drilling using magneto-rheological fluid damper [J]. J Mater Process Technol 55:2617–2626. https://doi.org/10.1016/j.jmatprotec.2014.05.029

Biermann D, Kirschner M (2015) Experimental investigations on single-lip deep hole drilling of superalloy Inconel 718 with small diameters [J]. J Manuf Process 20(1):332–339. https://doi.org/10.1016/j.jmapro.2015.06.001

Tnay GL, Wan S, Woon KS, Yeo SH (2016) The effects of dub-off angle on chip evacuation in single-lip deep hole gun drilling [J]. Int J Mach Tools Manuf 108:66–73. https://doi.org/10.1016/j.ijmachtools.2016.05.008

Maruda RW, Krolczyk GM, Nieslony P, Wojciechowski S, Michalski M, Legutko S (2016) The influence of the cooling conditions on the cutting tool wear and the chip formation mechanism [J]. J Manuf Process 24:107–115. https://doi.org/10.1016/j.jmapro.2016.08.006

Ladonne M, Cherif M, Landon Y, K'Nevez JY, Cahuc O, Castelbajac C (2015) Modelling the vibration-assisted drilling process: identification of influential phenomena [J]. Int J Adv Manuf Technol 81:1657–1666. https://doi.org/10.1007/s00170-015-7315-8

Pecat O, Meyer I (2013) Low frequency vibration assisted drilling of aluminium alloys [J]. Adv Mater Res 769:131–138. https://doi.org/10.4028/www.scientific.net/AMR.769.131

Sahu SH, DeVor RE, Kapoor SH (2004) Modeling of forces for drills with Chip-breaking grooves [J]. J Manuf Sci Eng 126:555–564. https://doi.org/10.1115/1.1763183

Jung J, Ke F (2007) A gundrilling force system [J]. Int J Mach Tools Manuf 47:1276–1284. https://doi.org/10.1016/j.ijmachtools.2006.08.018

Woon KS, Chaudhari A, Rahman M, Wan S, Kumar AS (2014) The effects of tool edge radius on drill deflection and hole misalignment in deep hole gundrilling of Inconel-718 [J]. CIRP Ann Manuf Technol 63(1):125–128. https://doi.org/10.1016/j.cirp.2014.03.075

Biermann D, Kersting M, Kessler N (2009) Process adapted structure optimization of deep hole drilling tools [J]. CIRP Ann Manuf Technol 58(1):89–92. https://doi.org/10.1016/j.cirp.2009.03.102

Zhu ZW, To S, Zhu WL, Huang P, Zhou XQ (2019) Cutting forces in fast−/slow tool servo diamond turning of micro-structured surfaces [J]. Int J Mach Tools Manuf 136:62–75. https://doi.org/10.1016/j.ijmachtools.2018.09.003

Yu DG (2017) Self-centering positioner and principle for locating and guiding deep-hole drills using oil films [J]. Int J Adv Manuf Technol 92:639–649. https://doi.org/10.1007/s00170-017-0185-5

Armarego EJA, Whitfield RC (1985) Computer based modeling of popular machining operations for forces and power prediction [J]. Annals of the CIRP 34(1):65–69. https://doi.org/10.1016/S0007-8506(07)61725-9

Altintas Y, Kilic ZM (2013) Generalized dynamic model of metal cutting operations [J]. CIRP Ann Manuf Technol 62(1):47–50. https://doi.org/10.1016/j.cirp.2013.03.034

Zhang H, Shen XQ, Bo A, Li YM, Zhan HF, Gu YT (2017) A multiscale evaluation of the surface integrity in boring trepanning association deep hole drilling [J]. Int J Mach Tools Manuf 123:48–56. https://doi.org/10.1016/j.ijmachtools.2017.07.005

Griffiths BJ (1993) Modelling complex force systems, Part1: the cutting and pad forces in deep drilling [J]. J Manuf Sci Eng 115(2):169–176. https://doi.org/10.1115/1.2901647

Li XB, Zheng JM, Li Y, Kong LF, Shi WC, Guo B (2018) Modeling and distribution laws of drilling force for staggered teeth BTA deep hole drill [J]. Math Probl Eng 3691468:1–13. https://doi.org/10.1155/2018/3691468

Richardson R, Bhatti R (2001) A review of research into the role of guide pads in BTA deep-hole machining [J]. J Mater Process Technol 110(1):61–69. https://doi.org/10.1016/S0924-0136(00)00733-0

Wan M, Pan WJ, Zhang WH, Ma YC, Yang Y (2014) A unified instantaneous cutting force model for flat end mills with variable geometries [J]. J Mater Process Technol 214(3):641–650. https://doi.org/10.1016/j.jmatprotec.2013.10.016

Shamoto E, Altintas Y (1999) Prediction of shear angle in oblique cutting with maximum shear stress and minimum energy principles [J]. J Manuf Sci Eng 121:399–407. https://doi.org/10.1115/1.2832695

Zhang X, Ehmann KF, Yu T, Wang W (2016) Cutting forces in micro-end-milling processes [J]. Int J Mach Tools Manuf 107:21–40. https://doi.org/10.1016/j.ijmachtools.2016.04.012

Thil J, Haddag B, Nouari M, Barlier C, Papillon L (2014) Experimental and analytical analyses of the cutting process in the deep hole drilling with BTA (boring trepanning association) system [J]. Mechanics and Industry 14(6):413–429. https://doi.org/10.1051/meca/2013087

Funding

This research has been supported by the National Natural Science Foundation of China (Grant No. 51475367), National Science and Technology Major Project of China (Grant No. 2013ZX04009011), Natural Science Foundation of Department of Education of Shaanxi Province (Grant No. 2018JM5113), and Key Laboratory Project of Shaanxi Education Department (Grant No. 17JS093).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, X., Zheng, J., Li, Y. et al. Modeling and experimental investigation of drilling force for low-frequency axial vibration-assisted BTA deep hole drilling. Int J Adv Manuf Technol 111, 1721–1733 (2020). https://doi.org/10.1007/s00170-020-06162-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06162-4