Abstract

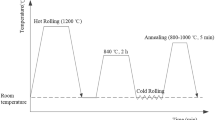

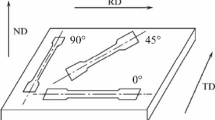

A systematic study was carried out to evaluate the effects of cold rolling and annealing processes on the ridging severity of ferritic stainless steel (FSS). Both microstructural refinement and texture optimisation were achieved with an optimised processing schedule to improve the ridging resistance of FSS. Coarse grain bands comprising of primarily {112} <110> oriented grains were found to form inside cold-rolled and annealed FSS sheets. The effects of annealing schedules and the resultant microstructure and texture on the ridging behaviour of FSS are discussed. The results indicate that the reduction in the fraction of {001} <110> orientation by optimisation of the rolling processes contributes to reduce the ridging height of the FSS during the subsequent forming process. Through extending soaking time and under 880 °C during final annealing step, a maximum of 30% reduction in ridging height can be achieved with a refined microstructure and texture of FSS, improving the surface quality of FSS during subsequent forming processes.

Similar content being viewed by others

References

Chao HC (1967) The mechanism of ridging in ferritic stainless steels. Trans ASM 60(1):37–50

Takechi H, Kato H, Sunami T, Nakayama T (1967) The mechanism of ridging phenomenon in 17% chromium stainless steel sheets. Trans JIM 31(6):717–723

Engler O, Schafer C, Brinkman HJ (2012) Crystal-plasticity simulation of the correlation of microstructure and roping in AA 6xxx Al-Mg-Si sheet alloys for automotive applications. Acta Mater 60:5217–5232

Knutsen R, Wittridge N (2002) Modelling surface ridging in ferritic stainless steel. Mater Sci Technol 18:1279–1285

Huh M, Engler O (2001) Effect of intermediate annealing on texture, formability and ridging of 17% Cr ferritic stainless steel sheet. Mater Sci Eng A 308:74–87

Bennett T, Petrov R, Kesten L (2009) Texture-induced surface roping in an automotive aluminium sheet. Scr Mater 61:733–736

Baczynski G, Guzzo R, Ball M, Lloyd D (2000) Development of roping in an aluminium automotive alloy AA6111. Acta Mater 48:3361–3376

Patra S, Singhal L (2013) Influence of hot band annealing and cold rolling on texture and ridging of 430 stainless steel containing aluminum. Mater Sci Appl 4:70–76

Patra S, Ghosh A, Sood J, Singhal LK, Podder AS, Chakrabarti D (2016) Effect of coarse grain band on the ridging severity of 409L ferritic stainless steel. Mater Des 106:336–348

Zhang C, Liu Z, Wang G (2011) Effects of hot rolled shear bands on formability and surface ridging of an ultra purified 21%Cr ferritic stainless steel. J Mater Process Technol 211:1051–1059

Gao F, Yu F, Misra R, Zhang X, Zhang S, Liu Z (2015) Microstructure, texture, and deep drawability under two different cold-rolling processes in ferritic stainless steel. J Mater Eng Perform 24:3862–3880

Park J, Park S (2012) Effect of heat treatment on a ridging phenomenon of ferritic stainless steels. Metal

Han J, Li H, Zhu Z, Jiang L, Xu H, Ma L (2014) Effects of processing optimisation on microstructure, texture, grain boundary and mechanical properties of Fe-17Cr ferritic stainless steel thick plates. Mater Sci Eng A 616:20–28

Mola J, Jung I, Park J, Chae D, Cooman B Ridging control in transformable ferritic stainless steels. Metall Mater Trans A 43:228–244

Dorner D, Zaefferer S, Raabe D (2007) Retention of the Goss orientation between microbands during cold rolling of an Fe3%Si single crystal. Acta Mater 55(7):2519–2530

Zaefferer S, Baudin T, Penelle R (2001) A study of the formation mechanisms of the cube recrystallization texture in cold rolled Fe-36%Ni alloys. Acta Mater 49(6):1105–1122

ASTM Standard E8-E8M -08 (2008) Standard test methods for tension testing of metallic materials. ASTM International, West Conshohocken

Kang SG, Kobayashi T (2004) Asymmetric rolling as means of texture and ridging control and grain refinement of aluminum alloy and steel sheets. Mater Sci Forum 449:1–6

Ma XG, Zhao JW, Du W, Zhang X, Jiang ZY (2017) An analysis of ridging of ferritic stainless steel 430. Mater Sci Eng A 685(8):358–366

Ma X, Zhao J, Du W, Zhang X, Jiang Z (2018) Effect of rolling processes on ridging generation of ferritic stainless steel. Mater Charact 137:201–211

Siqueira R, Sandim H, Oliveira T, Raabe D Composition and orientation effects on the final recrystallisation texture of coarse-grained Nb-containing AISI 430 ferritic stainless steels. Mater Sci Eng A 528:3513–3519

Hawakaya Y, Szpunar J, Paulambo G, Lin P (1996) The role of grain boundary character distribution in goss texture development of electrical steel. J Magn Magn Mater 160:143–144

Lefebvre G, Sinclair CW, Lebensohn R, Mithieux JD (2012) Model Simul Mater Sci Eng 20:1–16

Jung I, Mola J, Chae D, Coonan BC (2010) Influence of the cold rolling and annealing sequence on the ridging behaviour of Ti-stabilized 18% Cr ferritic stainless steel. Int J Steel Res 81(12):1089–1096

Howell P, Fleet D, Welch P, Ralph B (1978) Texture and grain boundary structure in tungsten-III. The primary misorientation function and grain boundary structure. Acta Metall 26:1499–1503

Raabe D, Sachtleber M, Weiland H, Scheele G, Zhao Z (2003) Grain-scale micromechanics of polycrystal surfaces during plastic straining. Acta Mater 51(6):1539–1560

Park S, Kim K, Lee Y, Park C (2002) Evolution of microstructure and texture associated with ridging in ferritic stainless steels. ISIJ Int 42:100–105

Shin HJ, An JK, Park SH, Lee DN (2003) The effect of texture on ridging of ferritic stainless steel. Acta Mater 51:4693–4706

Sellars C, Whitema J (1979) Recrystallisation and grain growth in hot rolling. Met Sci 13:187–194

Wright RN (1972) Anisotropic plastic flow in ferritic stainless steels and the roping phenomenon. Metall Trans 3(1):83–91

Viana C, Pinto A, Candido F, Matheus R (2006) Analysis of ridging in three ferritic stainless steel sheets. Mater Sci Technol 22:293–300

Huh M, Lee J, Park S, Engler O, Raabe D (2005) Effect of through-thickness macro and micro-texture gradients on ridging of 17%Cr ferritic stainless steel sheet. Steel Res Int 76(11):797–806

Acknowledgements

The first author would like to thank the financial support by IPTA scholarship from University of Wollongong for his PhD study. The authors wish to gratefully acknowledge the help of Dr. Madeleine Strong Cincotta in the final language editing of this paper.

Funding

The study is also supported by Baosteel Australia Joint Research and Development Centre (BAJC).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ma, X., Zhao, J., Du, W. et al. Effects of cold rolling and annealing on the ridging behaviour of ferritic stainless steel. Int J Adv Manuf Technol 107, 4823–4836 (2020). https://doi.org/10.1007/s00170-020-05367-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05367-x