Abstract

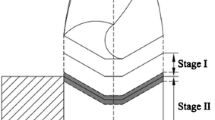

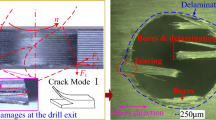

Burrs generated in the drilling process of carbon fiber-reinforced polymers (CFRPs) can cause delamination, therefore significantly reduce the bearing capacity of the components during service. In order to address this issue, the multiscale finite element (FE) modeling was developed in this work to analyze the burrs formation mechanism. The proposed model combined the microscopic fiber and matrix phases with the macroscopic equivalent homogeneous material (EHM). Meanwhile, 3D Hashin-type damage initiation criteria were proposed to characterize the differences between the tensile and compressive strength of the EHM and fiber and their anisotropy feature. The cutting of the fiber and matrix phases under all cutting angles were divided into two simulation processes to improve the computational efficiency. With the help of this model, the thrust force was accurately predicted where the distribution of burrs was successfully simulated compared with the experimental measurements. In addition, the evolution process from the failure of the fiber and matrix phases towards formation of the burrs was clarified. It could be seen that in the drilling of the CFRPs at the hole exit, the matrix was removed while the fibers deformed out-of-plane under the push of the drill firstly rather than got removed and then bent with the rotation of the drill. Specifically, the fibers under acute cutting angles bent outward the hole radially, which made them more difficult to be removed and hence resulted in the burrs eventually. The revealed formation mechanisms would be the crucial contribution and guidance for helping to suppress the burrs.

Similar content being viewed by others

References

Che D, Saxena I, Han P, Guo P, Ehmann KF (2014) Machining of carbon fiber reinforced plastics/polymers: a literature review. J Manuf Sci Eng Trans ASME 136(34):1–22. https://doi.org/10.1115/1.4026526

Abrão AM, Faria PE, Rubio JCC, Reis P, Davim JP (2007) Drilling of fiber reinforced plastics: a review. J Mater Process Technol 186(1–3):1–7. https://doi.org/10.1016/j.jmatprotec.2006.11.146

Khashaba UA (2012) Drilling of polymer matrix composites: a review. J Compos Mater 47(15):1817–1832. https://doi.org/10.1177/0021998312451609

Dandekar CR, Shin YC (2012) Modeling of machining of composite materials: a review. Int J Mach Tool Manu 57:102–121. https://doi.org/10.1016/j.ijmachtools.2012.01.006

Wang H, Ning FD, Hu YB, Cong WL (2018) Surface grinding of CFRP composites using rotary ultrasonic machining: a comparison of workpiece machining orientations. Int J Adv Manuf Technol 95(5–8):2917–2930. https://doi.org/10.1007/s00170-017-1401-z

Geier N, Szalay T, Takács M (2019) Analysis of thrust force and characteristics of uncut fibres at non-conventional oriented drilling of unidirectional carbon fibre-reinforced plastic (UD-CFRP) composite laminates. Int J Adv Manuf Technol 100:3139–3154. https://doi.org/10.1007/s00170-018-2895-8

Wang H, Cong WL, Ning FD, Hu YB (2018) A study on the effects of machining variables in surface grinding of CFRP composites using rotary ultrasonic machining. Int J Adv Manuf Technol 95(9–12):3651–3663. https://doi.org/10.1007/s00170-017-1468-6

Azmi AI, Lin RJT, Bhattacharyya D (2012) Experimental study of machinability of GFRP composites by end milling. Mater Manuf Process 27(10):1045–1050. https://doi.org/10.1080/10426914.2012.677917

El-Sonbaty I, Khashaba UA, Machaly T (2004) Factors affecting the machinability of GFR/epoxy composites. Compos Struct 63(3–4):329–338. https://doi.org/10.1016/S0263-8223(03)00181-8

Faraz A, Biermann D, Weinert K (2009) Cutting edge rounding: an innovative tool wear criterion in drilling CFRP composite laminates. Int J Mach Tool Manu 49(15):1185–1196. https://doi.org/10.1016/j.ijmachtools.2009.08.002

Tan CL, Azmi AI, Muhammad N (2016) Delamination and surface roughness analyses in drilling hybrid carbon/glass composite. Mater Manuf Process 31(10):1366–1376. https://doi.org/10.1080/10426914.2015.1103864

Wang CY, Ming WW, An QL, Chen M (2017) Machinability characteristics evolution of CFRP in a continuum of fiber orientation angles. Mater Manuf Process 32(9):1041–1050. https://doi.org/10.1080/10426914.2016.1269915

Ning FD, Cong WL, Wang H, Hu YB, Hu ZL, Pei ZJ (2017) Surface grinding of CFRP composites with rotary ultrasonic machining: a mechanistic model on cutting force in the feed direction. Int J Adv Manuf Technol 92(1–4):1217–1229. https://doi.org/10.1007/s00170-017-0149-9

Wang H, Ning FD, Hu YB, Li YC, Wang XL, Cong WL (2018) Edge trimming of carbon fiber-reinforced plastic composites using rotary ultrasonic machining: effects of tool orientations. Int J Adv Manuf Technol 98(5–8):1641–1653. https://doi.org/10.1007/s00170-018-2355-5

Liu LP, Qi CL, Wu F, Xu JX, Zhu XM (2018) Experimental thrust forces and delamination analysis of GFRP laminates using candlestick drills. Mater Manuf Process 33(6):695–708. https://doi.org/10.1080/10426914.2017.1376072

Dharan CKH, Won MS (2000) Machining parameters for an intelligent machining system for composite laminates. Int J Mach Tool Manu 40(3):415–426. https://doi.org/10.1016/S0890-6955(99)00065-6

Iliescu D, Gehin D, Iordanoff I, Girot F, Gutiérrez ME (2010) A discrete element method for the simulation of CFRP cutting. Compos Sci Technol 70(1):73–80. https://doi.org/10.1016/j.compscitech.2009.09.007

Jia ZY, Fu R, Wang FJ, Qian BW, He CL (2018) Temperature effects in end milling carbon fiber reinforced polymer composites. Polym Compos 39(2):437–447. https://doi.org/10.1002/pc.23954

Wang FJ, Qian BW, Jia ZY, Fu R, Cheng D (2017) Secondary cutting edge wear of one-shot drill bit in drilling CFRP and its impact on hole quality. Compos Struct 178:341–352. https://doi.org/10.1016/j.compstruct.2017.04.024

Bhatnagar N, Nayak D, Singh I, Chouhan H, Mahajan P (2004) Determination of machining-induced damage characteristics of fiber reinforced plastic composite laminates. Mater Manuf Process 19(6):1009–1023. https://doi.org/10.1081/LMMP-200035177

Sheikh-Ahmad J, Urban N, Cheraghi H (2012) Machining damage in edge trimming of CFRP. Mater Manuf Process 27(7):802–808. https://doi.org/10.1080/10426914.2011.648253

Wang FJ, Qian BW, Jia ZY, Cheng D, Fu R (2018) Effects of cooling position on tool wear reduction of secondary cutting edge corner of one-shot drill bit in drilling CFRP. Int J Adv Manuf Technol 94(9–12):4277–4287. https://doi.org/10.1007/s00170-017-1103-6

Shi Y, Pinna C, Soutis C (2014) Modelling impact damage in composite laminates: a simulation of intra- and inter-laminar cracking. Compos Struct 114:10–19. https://doi.org/10.1016/j.compstruct.2014.03.052

Shi Y, Soutis C (2016) Modelling transverse matrix cracking and splitting of cross-ply composite laminates under four point bending. Theor Appl Fract Mech 83:73–81. https://doi.org/10.1016/j.tafmec.2015.11.006

Zenia S, Ben Ayed L, Nouari M, Delamézière A (2015) Numerical analysis of the interaction between the cutting forces, induced cutting damage, and machining parameters of CFRP composites. Int J Adv Manuf Technol 78:465–480. https://doi.org/10.1007/s00170-014-6600-2

Soldani X, Santiuste C, Muñoz-Sánchez A, Miguélez MH (2011) Influence of tool geometry and numerical parameters when modeling orthogonal cutting of LFRP composites. Compos Part A 42(9):1205–1216. https://doi.org/10.1016/j.compositesa.2011.04.023

Wang FJ, Wang XN, Yang R, Gao HQ, Su YL, Bi GJ (2017) Research on the carbon fibre-reinforced plastic (CFRP) cutting mechanism using macroscopic and microscopic numerical simulations. J Reinf Plast Compos 36(8):555–562. https://doi.org/10.1177/0731684416684966

Faraz A, Biermann D (2013) In situ qualitative inspection of hole exit delamination at bottom-ply during drilling of woven CFRP epoxy composite laminates. Adv Eng Mater 15(6):449–463. https://doi.org/10.1002/adem.201200342

Bai Y, Jia ZY, Wang FJ, Fu R, Guo HB, Cheng D, Zhang BY (2017) Influence of drill helical direction on exit damage development in drilling carbon fiber reinforced plastic. IOP Conf Ser Mater Sci Eng 213:012015. https://doi.org/10.1088/1757-899X/213/1/012015

Fu R, Jia ZY, Wang FJ, Jin Y, Sun D, Yang LJ, Cheng D (2018) Drill-exit temperature characteristics in drilling of UD and MD CFRP composites based on infrared thermography. Int J Mach Tool Manu 135:24–37. https://doi.org/10.1016/j.ijmachtools.2018.08.002

Shi Y, Swait T, Soutis C (2012) Modelling damage evolution in composite laminates subjected to low velocity impact. Compos Struct 94(9):2902–2913. https://doi.org/10.1016/j.compstruct.2012.03.039

Santiuste C, Miguélez H, Soldani X (2011) Out-of-plane failure mechanisms in LFRP composite cutting. Compos Struct 93(11):2706–2713. https://doi.org/10.1016/j.compstruct.2011.05.034

Isbilir O, Ghassemieh E (2012) Finite element analysis of drilling of carbon fibre reinforced composites. Appl Compos Mater 19(3–4):637–656. https://doi.org/10.1007/s10443-011-9224-9

Isbilir O, Ghassemieh E (2013) Numerical investigation of the effects of drill geometry on drilling induced delamination of carbon fiber reinforced composites. Compos Struct 105:126–133. https://doi.org/10.1016/j.compstruct.2013.04.026

Phadnis VA, Makhdum F, Roy A, Silberschmidt VV (2012) Drilling-induced damage in CFRP laminates: experimental and numerical analysis. Solid State Phenom 188:150–157. https://doi.org/10.4028/www.scientific.net/SSP.188.150

Phadnis VA, Makhdum F, Roy A, Silberschmidt VV (2013) Drilling in carbon/epoxy composites: experimental investigations and finite element implementation. Compos Part A 47:41–51. https://doi.org/10.1016/j.compositesa.2012.11.020

Feito N, López-Puente J, Santiuste C, Miguélez MH (2014) Numerical prediction of delamination in CFRP drilling. Compos Struct 108:677–683. https://doi.org/10.1016/j.compstruct.2013.10.014

Feito N, Diaz-Álvarez J, López-Puente J, Miguelez MH (2016) Numerical analysis of the influence of tool wear and special cutting geometry when drilling woven CFRPs. Compos Struct 138:285–294. https://doi.org/10.1016/j.compstruct.2015.11.065

Al-wandi S, Ding S, Mo J (2017) An approach to evaluate delamination factor when drilling carbon fiber-reinforced plastics using different drill geometries: experiment and finite element study. Int J Adv Manuf Technol 93:4043–4061. https://doi.org/10.1007/s00170-017-0880-2

Calzada KA, Kapoor SG, DeVor RE, Samuel J, Srivastava AK (2012) Modeling and interpretation of fiber orientation-based failure mechanisms in machining of carbon fiber-reinforced polymer composites. J Manuf Process 14(2):141–149. https://doi.org/10.1016/j.jmapro.2011.09.005

Kozey VV, Jiang H, Mehta VR, Kumar S (1995) Compressive behavior of materials: part II. High performance fibers. J Mater Res 10(4):1044–1061. https://doi.org/10.1557/JMR.1995.1044

Deborah DLC (2017) Carbon composites: composites with carbon fibers, Nanofibers and nanotubes. Buffalo, New York

Ueda M, Saito W, Imahori R, Kanazawa D, Jeong T (2014) Longitudinal direct compression test of a single carbon fiber in a scanning electron microscope. Compos Part A 67:96–101. https://doi.org/10.1016/j.compositesa.2014.08.021

Zhou Y, Jiang D, Xia Y (2001) Tensile mechanical behavior of T300 and M40J fiber bundles at different strain rate. J Mater Sci 36:919–922. https://doi.org/10.1023/A:1004803202658

Su Y (2019) Effect of the cutting speed on the cutting mechanism in machining CFRP. Compos Struct 220:662–676. https://doi.org/10.1016/j.compstruct.2019.04.052

Dassault Systèmes (2015) Abaqus/CAE User’s Guide

Rao GVG, Mahajan P, Bhatnagar N (2007) Machining of UD-GFRP composites chip formation mechanism. Compos Sci Technol 67(11–12):2271–2281. https://doi.org/10.1016/j.compscitech.2007.01.025

Jia ZY, Fu R, Niu B, Qian BW, Bai Y, Wang FJ (2016) Novel drill structure for damage reduction in drilling CFRP composites. Int J Mach Tool Manu 110:55–65. https://doi.org/10.1016/j.ijmachtools.2016.08.006

Hortig C, Svendsen B (2007) Simulation of chip formation during high-speed cutting. J Mater Process Technol 186(1–3):66–76. https://doi.org/10.1016/j.jmatprotec.2006.12.018

Rao GVG, Mahajan P, Bhatnagar N (2007) Micro-mechanical modeling of machining of FRP composites-cutting force analysis. Compos Sci Technol 67(3–4):579–593. https://doi.org/10.1016/j.compscitech.2006.08.010

Liu H, Xie W, Sun Y, Zhang J, Chen N (2018) Investigations on micro-cutting mechanism and surface quality of carbon fiber-reinforced plastic composites. Int J Adv Manuf Technol 94:3655–3664. https://doi.org/10.1007/s00170-017-1110-7

Xu W, Zhang L (2017) A new approach to characterising the surface integrity of fibre-reinforced polymer composites during cutting. Compos Part A 103:272–282. https://doi.org/10.1016/j.compositesa.2017.10.015

Cheng H, Gao J, Kafka OL, Zhang K, Luo B, Liu WK (2017) A micro-scale cutting model for UD CFRP composites with thermo-mechanical coupling. Compos Sci Technol 153:18–31. https://doi.org/10.1016/j.compscitech.2017.09.028

Gao C, Xiao J, Xu J, Ke Y (2016) Factor analysis of machining parameters of fiber-reinforced polymer composites based on finite element simulation with experimental investigation. Int J Adv Manuf Technol 83:1113–1125. https://doi.org/10.1007/s00170-015-7592-2

Yang L, Yan Y, Kuang N (2013) Experimental and numerical investigation of aramid fibre reinforced laminates subjected to low velocity impact. Polym Test 32(7):1163–1173. https://doi.org/10.1016/j.polymertesting.2013.07.010

TORAY. Physical property table of Torayca yarn. http://www.torayca.com/en/download/pdf/torayca.pdf

Acknowledgments

The authors wish to thank the anonymous reviewers for their comments which lead to improvements of this paper. The authors also gratefully extend their acknowledgements to Prof. Yu Shi for his advices and contributions to the revision of the manuscript.

Funding

This work is financially supported by the National Natural Science Foundation of China (No. 51575082), the National Natural Science Foundation of China-United with Liaoning Province (No. U1508207), the National Key Basic Research Program of China (973 Program, No. 2014CB046503), the National Innovative Research Group (No. 51321004), Fundamental Research Funds for the Central Universities (No. DUT16TD01), and Young Scientists Fund of the National Natural Science Foundation of China (No. 51505064).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, F., Wang, X., Zhao, X. et al. A numerical approach to analyze the burrs generated in the drilling of carbon fiber reinforced polymers (CFRPs). Int J Adv Manuf Technol 106, 3533–3546 (2020). https://doi.org/10.1007/s00170-019-04872-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04872-y