Abstract

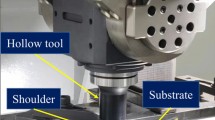

Selection of appropriate welding parameters in micro-friction stir welding (micro-FSW) is challenging and a practical problem. In this regard, an assessment of variation in the favourable process parameters due to downscaling of sheet thickness can prove beneficial. In this work, FSW in 1- and 0.5-mm-thick AA6061-T6 sheets was compared for suitable process parameters based on the tensile strength of the weld. Comparatively high tool rotational speed combined with a high speed of tool travel and low plunge depth was found to be suitable welding parameters in micro-FSW (0.5-mm sheet). The effect of using this favourable set of process parameter was also assessed on frictional heat input requirement per unit weld volume, deformation conditions during welding (predicted using FEM simulation) and weld’s mechanical properties and microstructural characteristics in each sheet thickness. A high frictional heat input per unit weld volume was found in micro-FSW. A reduced weld zone temperature, an increased value of strain rate and a higher cooling rate were found in micro-FSW which led to a smaller weld nugget grain size, an improvement in weld’s ultimate tensile strength (UTS) but a drop in its ductility in this case.

Similar content being viewed by others

References

Gibson BT, Lammlein DH, Prater TJ, Longhurst WR, Cox CD, Ballun MC, Dharmaraj KJ, Cook GE, Strauss AM (2014) Friction stir welding: process, automation, and control. J Manuf Process 16:56–73. https://doi.org/10.1016/j.jmapro.2013.04.002

Shah PH, Badheka VJ (2017) Friction stir welding of aluminium alloys: an overview of experimental findings–process, variables, development and applications. Proc Inst Mech Eng L J Mater Des Appl. https://doi.org/10.1177/1464420716689588

Kesharwani RK, Panda SK, Pal SK (2014) Multi objective optimization of friction stir welding parameters for joining of two dissimilar thin aluminum sheets. Procedia Mater Sci 6:178–187. https://doi.org/10.1016/j.mspro.2014.07.022

Teh N, Goddin H, Whitaker A (2011) Developments in micro applications of friction stir welding. Cambridge UK TWI Dense. https://www.twi-global.com/technical-knowledge/published-papers/developments-in-micro-applications-of-friction-stir-welding/. Accessed 30 May 2018

Ahmed S, Shubhrant A, Deep A, Saha P (2014) Development and analysis of butt and lap welds in micro friction stir welding (μFSW). In: Advances in material forming and joining. Springer, New Delhi, pp 295–306

Sithole K, Rao VV (2016) Recent developments in micro friction stir welding: a review. IOP Conf Ser Mater Sci Eng 114. https://doi.org/10.1088/1757-899X/114/1/012036

Sattari S, Bisadi H, Sajed M (2012) Mechanical properties and temperature distributions of thin friction stir welded sheets of AA5083. Int J Mech Appl 2:1–6. https://doi.org/10.5923/j.mechanics.20120201.01

Ahmed S, Saha P (2018) Development and testing of fixtures for friction stir welding of thin aluminium sheets. J Mater Process Technol 252:242–248. https://doi.org/10.1016/j.jmatprotec.2017.09.034

Scialpi A, De Giorgi M, De Filippis LAC, Nobile R, Panella FW (2008) Mechanical analysis of ultra-thin friction stir welding joined sheets with dissimilar and similar materials. Mater Des 29:928–936. https://doi.org/10.1016/j.matdes.2007.04.006

Huang Y, Meng X, Zhang Y, Cao J, Feng J (2017) Micro friction stir welding of ultra-thin Al-6061 sheets. J Mater Process Technol 250:313–319. https://doi.org/10.1016/j.jmatprotec.2017.07.031

Ni Y, Fu L, Chen HY (2019) Effects of travel speed on mechanical properties of AA7075-T6 ultra-thin sheet joints fabricated by high rotational speed micro pinless friction stir welding. J Mater Process Technol 265:63–70. https://doi.org/10.1016/j.jmatprotec.2018.10.006

Liu FJ, Fu L, Chen HY (2018) Effect of high rotational speed on temperature distribution, microstructure evolution, and mechanical properties of friction stir welded 6061-T6 thin plate joints. Int J Adv Manuf Technol 96:1823–1833. https://doi.org/10.1007/s00170-018-1736-0

Papaefthymiou S, Goulas C, Gavalas E (2015) Micro-friction stir welding of titan zinc sheets. J Mater Process Technol 216:133–139. https://doi.org/10.1016/j.jmatprotec.2014.08.029

Yue Y, Wang G, Yang K, Wu B, Yan D (2018) Friction stir butt welding thin aluminum alloy sheets. Int J Adv Manuf Technol 96:3139–3147. https://doi.org/10.1007/s00170-018-1798-z

Wang K, Khan H, Li Z, Lyu S, Li J (2018) Micro friction stir welding of multilayer aluminum alloy sheets. J Mater Process Technol 260:137–145. https://doi.org/10.1016/j.jmatprotec.2018.05.029

Zhang Z, Chen JT, Zhang ZW, Zhang HW (2011) Coupled thermo-mechanical model based comparison of friction stir welding processes of AA2024-T3 in different thicknesses. J Mater Sci 46:5815–5821. https://doi.org/10.1007/s10853-011-5537-1

Imam M, Biswas K, Racherla V (2013) On use of weld zone temperatures for online monitoring of weld quality in friction stir welding of naturally aged aluminium alloys. Mater Des 52:730–739. https://doi.org/10.1016/j.matdes.2013.06.014

Doley JK, Kore SD (2016) A study on friction stir welding of dissimilar thin sheets of aluminum alloys AA 5052–AA 6061. J Manuf Sci Eng 138:114502. https://doi.org/10.1115/1.4033691

Ahmed S, Saha P (2017) Study of process parameters and joint properties in friction stir welding of thin and ultra-thin aluminium alloy 6061-T6 sheets. In: Proc COPEN, IIT Madras, India pp 271-274

He X, Gu F, Ball A (2014) A review of numerical analysis of friction stir welding. Prog Mater Sci 65:1–66. https://doi.org/10.1016/j.pmatsci.2014.03.003

Ahmed S, Saha P (2015) Downscaling the process of friction stir welding: an analysis of temperature distributions in: Proc IHMTC, Thiruvanandapuram

Hwang J, Kompella S, Chandrasekar S, Farris TN (2003) Measurement of temperature field in surface grinding using infra-red (IR) imaging system. J Tribol 125:377. https://doi.org/10.1115/1.1537748

Kobayashi S, Oh SI, Altan T (1989) Metal forming and the finite-element method. Oxford Series

Li G, Jinn JT, Wu WT, Oh SI (2001) Recent development and applications of three-dimensional finite element modeling in bulk forming processes. J Mater Process Technol 113:40–45. https://doi.org/10.1016/S0924-0136(01)00590-8

Jain R, Pal SK, Singh SB (2016) A study on the variation of forces and temperature in a friction stir welding process: a finite element approach. J Manuf Process 23:278–286. https://doi.org/10.1016/j.jmapro.2016.04.008

Lesuer DR, Kay GJ, LeBlanc MM (2001) Modeling large strain, high-rate deformation in metals. Modeling the performance of engineering structural materials II. In: Proceedings of a symposium sponsored by the SMD of TMS, Indianapolis, IN, pp 75–86. https://e-reports-ext.llnl.gov/pdf/243782.pdf

Al-Badour F, Merah N, Shuaib A, Bazoune A (2013) Coupled Eulerian Lagrangian finite element modeling of friction stir welding processes. J Mater Process Technol 213:1433–1439. https://doi.org/10.1016/j.jmatprotec.2013.02.014

Buffa G, Ducato A, Fratini L (2011) Numerical procedure for residual stresses prediction in friction stir welding. Finite Elem Anal Des 47(4):470–476. https://doi.org/10.1016/j.finel.2010.12.018

Vijayan S, Raju R, Subbaiah K, Sridhar N, Rao SRK (2010) Friction stir welding of Al–mg alloy optimization of process parameters using Taguchi method. Exp Techn 34(5):37–44. https://doi.org/10.1111/j.1747-1567.2009.00563.x

Elatharasan G, Kumar VS (2013) An experimental analysis and optimization of process parameter on friction stir welding of AA 6061-T6 aluminium alloy using RSM. Procedia Eng 64:1227–1234. https://doi.org/10.1016/j.proeng.2013.09.202

Jayaraman M, Sivasubramanian R, Balasubramanian V, Lakshminarayanan AK (2009) Optimization of process parameters for friction stir welding of cast aluminium alloy A319 by Taguchi method. J Sci Ind Res 68(1):36–43 http://nopr.niscair.res.in/bitstream/123456789/2786/1/JSIR%2068%281%29%2036-43.pdf

Schmidt H, Hattel J, Wert J (2004) An analytical model for the heat generation in friction stir welding. Model Simul Mater Sci Eng 12:143–157. https://doi.org/10.1088/0965-0393/12/1/013

Gadakh VS, Adepu K (2013) Heat generation model for taper cylindrical pin profile in FSW. J Mater Res Technol 2:370–375. https://doi.org/10.1016/j.jmrt.2013.10.003

Hamilton C, Dymek S, Sommers A (2008) A thermal model of friction stir welding in aluminum alloys. Int J Mach Tools Manuf 48:1120–1130. https://doi.org/10.1016/j.ijmachtools.2008.02.001

Nandan R, Roy GG, Debroy T (2006) Numerical simulation of three-dimensional heat transfer and plastic flow during friction stir welding. Metall Mater Trans A 37(4):1247–1259. https://doi.org/10.1007/s11661-006-1076-9

Humphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena. Elsevier Ltd

Gerlich A, Yamamoto M, North TH (2007) Strain rates and grain growth in Al 5754 and Al 6061 friction stir spot welds. Metall Mater Trans A Phys Metall Mater Sci 38:1291–1302. https://doi.org/10.1007/s11661-007-9155-0

Chang CI, Lee CJ, Huang JC (2004) Relationship between grain size and Zener-Holloman parameter during friction stir processing in AZ31 mg alloys. Scr Mater 51:509–514. https://doi.org/10.1016/j.scriptamat.2004.05.043

Malopheyev S, Vysotskiy I, Kulitskiy V, Mironov S, Kaibyshev R (2016) Optimization of processing-microstructure-properties relationship in friction-stir welded 6061-T6 aluminum alloy. Mater Sci Eng A 662:136–143. https://doi.org/10.1016/j.msea.2016.03.063

He J, Ling Z, Li H (2016) Effect of tool rotational speed on residual stress, microstructure, and tensile properties of friction stir welded 6061-T6 aluminum alloy thick plate. Int J Adv Manuf Technol 84:1953–1961. https://doi.org/10.1007/s00170-015-7859-7

Vargas JA, Torres JE, Pacheco JA, Hernandez RJ (2013) Analysis of heat input effect on the mechanical properties of Al-6061-T6 alloy weld joints. Mater Des 52:556–564. https://doi.org/10.1016/j.matdes.2013.05.081

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ahmed, S., Saha, P. Selection of optimal process parameters and assessment of its effect in micro-friction stir welding of AA6061-T6 sheets. Int J Adv Manuf Technol 106, 3045–3061 (2020). https://doi.org/10.1007/s00170-019-04840-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04840-6