Abstract

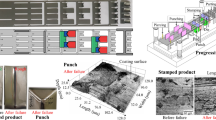

A new method for the prediction of die wear is established by studying the wear characteristics of automobile panels stamping dies. This method takes into account the contact pressure, the change of wear coefficient and material hardness along the thickness direction of the treatment layer. In order to obtain the relationship of wear coefficients with contact pressures and die hardness, a new kind of friction wear device is designed, which can simulate the wear environment of the blank-die interface in practical stamping. With this equipment, the dynamic wear coefficient considered the contact pressure and die hardness is obtained. Based on finite element software LS-DYNA, the prediction of die wear is achieved by using the dynamic coefficient and the continuously update of wear surface by means of the move of nodes. Based on wear at the feature line of an engine hood outer panel, the relationship between wear depth and stamping times is established. Comparing the prediction results of the new method and the traditional Archard method with the practical wear condition, the results show that the die life prediction method used in this study is closer to the practical condition; moreover, the accuracy is obviously higher than the traditional Archard method.

Similar content being viewed by others

References

Standard terminology relating to wear and erosion G40-01 (2002) Annual book of American society for testing and materials standards, vol. 3.02

Gåård A, Krakhmalev PV, Bergström J, Hallbäck N (2006) Galling resistance and wear mechanisms cold work tool materials sliding against carbon steel sheets. Tribol Lett 26:67–72

Gåård A (2013) Influence of tool microstructure on galling resistance. Tribol Int 57:251–256

Advanced high strength steel application guideline—version 5.0 (2014) World Auto Steel

Cser L, Geiger M, Lange K (1992) Tool life and tool quality in bulk metal forming. CIRP Ann Manuf Technol 41(2):667–675

Archard JF (1982) Microscopic aspects of adhesion and lubrication. Tribol Int 15(5):242

Hoffmann H, Nurnberg G, Nurnberg KE, Herrmann G (2007) A new approach to determine the wear coefficient for wear prediction of sheet metal forming tools. Prod Eng Res Devel 1:357–363

Alambeigi F, Khadem SM, Khorsand H, Hasan EMS (2016) A comparison of performance of artificial intelligence methods in prediction of dry sliding wear behavior. Int J Adv Manuf Technol 84:1981–1994

Dong WZH, Xu L, Lin QQ, Wang ZHG (2017) Experimental and numerical investigation on galling behavior in sheet metal forming process. Int J Adv Manuf Technol 88:1101–1109

Cora N, Koc M (2009) Experimental investigations on wear resistance characteristics of alternative die materials for stamping of advanced high-strength steels (AHSS). Int J Mach Tool Manu 49:897–905

Karlsson P, Gäärd A, Kralchmalev P, Bergstrom J (2012) Galling resistance and wear mechanisms for cold-work tool steels in lubricated sliding against high strength stainless steel sheets. Wear 286–287:92–97

Hou YK, Zhang WG, Yu ZHQ, Li SHH (2009) Selection of tool materials and surface treatments for improved galling performance in sheet metal forming. Int J Adv Manuf Technol 43:1010–1017

Cernuschi F, Guardamagna C, Capelli S, Lorenzoni L, Mack DE, Moscatelli A (2016) Solid particle erosion of standard and advanced thermal barrier coatings. Wear 348–349:43–51

Hatamia S, Nafarib A, Nyborga L, Jelvestama U (2010) Galling related surface properties of powder metallurgical tool steels alloyed with and without nitrogen. Wear 269:229–240

Gurumoorthy K, Kamaraj M, Rao KP, Venugopal S (2007) Development and use of combined wear testing equipment for evaluating galling and high stress sliding wear behaviour. Mater Des 28:987–992

Su YW, Chen W, Zhu AB, Xie YB (2009) Simulation of sliding wear based on finite element method and its application to wear prediction of link pivot joint. China Mech Eng 20(13):1573–1576

Podgornik B, Hogmark S, Pezdirnik J (2004) Comparison between different test methods for evaluation of galling properties of surface engineered tool surfaces. Wear 257:843–851

ASTM G98-02 (2009) Test method for galling resistance of materials. Latest accessed at http://www.astm.org/Standards/G98.htm

Yangui W, Guermazi N, Elleuch K (2017) Failure analysis of a cold work tool material slides against carbon steel in sheet metal forming process—a case study of hinges production. Int J Adv Manuf Technol 88:3151–3161

Määttä A, Vuoristo P, Mäntylä T (2001) Friction and adhesion of stainless steel strip against tool steels in unlubricated sliding with high contact load. Tribol Int 34:779–786

Atuanya CU, Ekweghiariri DI (2017) Experimental correlation between varying processing properties and wear behaviour of ternary Ni-Co-SiO2 composites coating of mild steel. Int J Adv Manuf Technol 88:2581–2588

Acknowledgements

The authors gratefully acknowledge the support from the National Key Research and Development Program of China (Item no. 2016YFB0300400). The authors would also like to thank SGMW Technology Center for providing test specimens for these studies and also thank them for their active interest in this work.

Funding

This work has been carried out with financial support from the National Key Research and Development Program of China (Item no. 2016YFB0300400).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qiao, X., Cheng, A., Nie, X. et al. A study on die wear prediction for automobile panels stamping based on dynamic model. Int J Adv Manuf Technol 97, 1823–1833 (2018). https://doi.org/10.1007/s00170-018-1811-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1811-6