Abstract

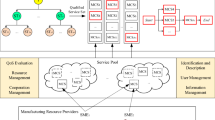

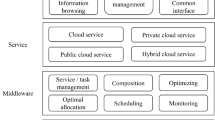

Cloud manufacturing is an emerging service-oriented manufacturing paradigm that integrates and manages distributed manufacturing resources through which complex manufacturing demands with a high degree of customization can be fulfilled. The process of service selection optimization and scheduling (SSOS) is an important issue for practical implementation of cloud manufacturing. In this paper, we propose new mixed-integer programming (MIP) models for solving the SSOS problem with basic composition structures (i.e., sequential, parallel, loop, and selective). Through incorporation of the proposed MIP models, the SSOS with a mixed composition structure can be tackled. As transportation is indispensable in cloud manufacturing environment, the models also optimize routing decisions within a given hybrid hub-and-spoke transportation network in which the central decision is to optimally determine whether a shipment between a pair of distributed manufacturing resources is routed directly or using hub facilities. Unlike the majority of previous research undertaken in cloud manufacturing, it is assumed that manufacturing resources are not continuously available for processing but the start time and end time of their occupancy interval are known in advance. The performance of the proposed models is evaluated through solving different scenarios in the SSOS. Moreover, in order to examine the robustness of the results, a series of sensitivity analysis are conducted on key parameters. The outcomes of this study demonstrate that the consideration of transportation and availability not only can change the results of the SSOS significantly, but also is necessary for obtaining more realistic solutions. The results also show that routing within a hybrid hub-and-spoke transportation network, compared with a pure hub-and-spoke network or a pure direct network, leads to more flexibility and has advantage of cost and time saving. The level of saving depends on the value of discount factor for decreasing transportation cost between hub facilities.

Similar content being viewed by others

References

Akbaripour H, Houshmand M, Valilai OF (2015) Cloud-based global supply chain: a conceptual model and multilayer architecture. J Manuf Sci Eng 137(4):31–36

Akbaripour H, Masehian E (2013) Efficient and robust parameter tuning for heuristic algorithms. Int J Ind Eng Prod Res 24(2):143–150

Akbaripour H, Masehian E (2017) Semi-lazy probabilistic roadmap: a parameter-tuned, resilient and robust path planning method for manipulator robots. Int J Adv Manuf Technol 89(5–8):1401–1430

Akbaripour H, Masehian E, Roostaei A (2017) Landscape analysis and scatter search metaheuristic for solving the uncapacitated single allocation hub location problem. Int J Ind Syst Eng 26(4):425–459

Ardagna D, Pernici B (2007) Adaptive service composition in flexible processes. IEEE Trans Softw Eng 33(6):369–384

Arkat J, Ghahve H (2014) Scheduling of virtual manufacturing cells with outsourcing allowed. Int J Comput Integr Manuf 27(12):1079–1089

Arora N et al (2008) Putting one-to-one marketing to work: personalization, customization, and choice. Mark Lett 19(3–4):305

Aykin T (1995) The hub location and routing problem. Eur J Oper Res 83(1):200–219

Banaszak ZA, Zaremba MB (2006) Project-driven planning and scheduling support for virtual manufacturing. J Intell Manuf 17(6):641–651

Benayoun R et al (1971) Linear programming with multiple objective functions: Step method (STEM). Math Program 1(1):366–375

Bennett DP, Yano CA (2004) A decomposition approach for an equipment selection and multiple product routing problem incorporating environmental factors. Eur J Oper Res 156(3):643–664

Campbell JF (1994) Integer programming formulations of discrete hub location problems. Eur J Oper Res 72(2):387–405

Cao Y et al (2016) A TQCS-based service selection and scheduling strategy in cloud manufacturing. Int J Adv Manuf Technol 82(1–4):235–251

Çetiner S, Sepil C, Süral H (2010) Hubbing and routing in postal delivery systems. Ann Oper Res 181(1):109–124

Chen X-J et al (2012) Resource reconstruction algorithms for on-demand allocation in virtual computing resource pool. Int J Autom Comput 9(2):142–154

Cheng Y et al (2017) Modeling of manufacturing service supply–demand matching hypernetwork in service-oriented manufacturing systems. Robot Comput Integr Manuf 45:59–72

Cheng Z et al (2014) Multitask oriented virtual resource integration and optimal scheduling in cloud manufacturing. J Appl Math 2014(1):1–9

Deb K, Miettinen K & Sharma D (2009) A hybrid integrated multi-objective optimization procedure for estimating nadir point. In International Conference on Evolutionary Multi-Criterion Optimization. pp. 569–583

Duflou JR et al (2012) Towards energy and resource efficient manufacturing: a processes and systems approach. CIRP Ann-Manuf Technol 61(2):587–609

Ebery J et al (2000) The capacitated multiple allocation hub location problem: formulations and algorithms. Eur J Oper Res 120(3):614–631

He W, Xu L (2014) A state-of-the-art survey of cloud manufacturing. Int J Comput Integr Manuf 28(3):239–250

Hsu C, Hsieh Y (2004) Direct versus hub-and-spoke routing on a maritime container network. J Mar Sci Technol 13(3):209–217

Hu SJ et al (2011) Assembly system design and operations for product variety. CIRP Ann-Manuf Technol 60(2):715–733

Huang B, Li C, Yin C et al (2013a) Cloud manufacturing service platform for small- and medium-sized enterprises. Int J Adv Manuf Technol 65(9–12):1261–1272

Huang B, Li C, Tao F (2013b) A chaos control optimal algorithm for QoS-based service composition selection in cloud manufacturing system. Enterp Inf Syst 8(4):445–463

Jin H, Yao X & Chen Y, (2015) Correlation-aware QoS modeling and manufacturing cloud service composition. J Intell Manuf, Available at: https://doi.org/10.1007/s10845-015-1080-2

Kesen SE, Das SK, Güngör Z (2010) A genetic algorithm based heuristic for scheduling of virtual manufacturing cells (VMCs). Comput Oper Res 37(6):1148–1156

Kurdi H et al (2015) A combinatorial optimization algorithm for multiple cloud service composition. Comput Electr Eng 42(0):107–113

Laporte G, Salazar-Gonzalez JJ, Semet F (2004) Exact algorithms for the job sequencing and tool switching problem. IIE Trans 36(1):37–45

Lartigau J et al (2015) Cloud manufacturing service composition based on QoS with geo-perspective transportation using an improved Artificial Bee Colony optimisation algorithm. Int J Prod Res 53(14):4380–4404

Li W et al (2015) Subtask scheduling for distributed robots in cloud manufacturing. IEEE Syst J 11(2):1–10

Lin C-C, Lin Y-J, Lin D-Y (2003) The economic effects of center-to-center directs on hub-and-spoke networks for air express common carriers. J Air Transp Manag 9(4):255–265

Liu B & Zhang Z (2016) QoS-aware service composition for cloud manufacturing based on the optimal construction of synergistic elementary service groups. Int J Adv Manuf Technol, Available at: https://doi.org/10.1007/s00170-016-8992-7

Liu J, Li C-L, Chan C-Y (2003a) Mixed truck delivery systems with both hub-and-spoke and direct shipment. Transp Res Part E: Logist Transp Rev 39(4):325–339

Liu L-L et al (2003b) Self-Organization Manufacturing Grid and its task scheduling algorithm. Comput Integr Manuf Syst 9(6):449–455

Liu N, Li X, Shen W (2014) Multi-granularity resource virtualization and sharing strategies in cloud manufacturing. J Netw Comput Appl 46:72–82

Liu W et al (2013) Study on multi-task oriented services composition and optimisation with the “Multi-Composition for Each Task” pattern in cloud manufacturing systems. Int J Comput Integr Manuf 26(8):786–805

Liu, Y. et al., 2016. Workload-based multi-task scheduling in cloud manufacturing. Robotics and Computer-Integrated Manufacturing, Available at: https://linkinghub.elsevier.com/retrieve/pii/S0736584516303210

Lu Y, Xu X, Xu J (2014) Development of a hybrid manufacturing cloud. J Manuf Syst 33(4):551–566

Magnusson M, Pasche M (2014) A contingency-based approach to the use of product platforms and modules in new product development. J Prod Innov Manag 31(3):434–450

Mahmutoğulları Aİ, Kara BY (2015) Hub location problem with allowed routing between nonhub nodes. Geogr Anal 47(4):410–430

Mai J et al (2016) Customized production based on distributed 3D printing services in cloud manufacturing. Int J Adv Manuf Technol 84(1–4):71–83

Manne AS (1960) On the job-shop scheduling problem. Oper Res 8(2):219–223

Masehian E, Akbaripour H, Mohabbati-Kalejahi N (2013) Landscape analysis and efficient metaheuristics for solving the n-queens problem. Comput Optim Appl 56(3):735–764

Nikolopoulou AI et al (2017) Moving products between location pairs: cross-docking versus direct-shipping. Eur J Oper Res 256(3):803–819

O’kelly ME (1987) A quadratic integer program for the location of interacting hub facilities. Eur J Oper Res 32(3):393–404

Ren L et al (2015) Cloud manufacturing: from concept to practice. Enterp Inf Syst 9:37–41

Ren L et al. (2014) Cloud manufacturing: key characteristics and applications. Int J Comput Integr Manuf, Available at: https://www.scopus.com/inward/record.url?eid=2-s2.0-84897355143&partnerID=tZOtx3y1

Seghir, F. & Khababa, A., 2016. A hybrid approach using genetic and fruit fly optimization algorithms for QoS-aware cloud service composition. J Intell Manuf, pp1–20

Shen Y, Yang X (2011) A self-optimizing QoS-aware service composition approach in a context sensitive environment. J Zhejiang Univ Sci C 12(3):221–238

Silva APD, Stam A (1997) A mixed integer programming algorithm for minimizing the training sample misclassification cost in two-group classification. Ann Oper Res 74:129–157

Song T et al (2014) Common engines of cloud manufacturing service platform for SMES. Int J Adv Manuf Technol 73(1–4):557–569

Tao F et al (2017) SDMSim: a manufacturing service supply–demand matching simulator under cloud environment. Robot Comput Integr Manuf 45:34–46

Tao F et al. (2011) Cloud manufacturing: a computing and service-oriented manufacturing model. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 225, pp.1969–1976

Tao F et al (2010) Correlation-aware resource service composition and optimal-selection in manufacturing grid. Eur J Oper Res 201(1):129–143

Tao F et al (2013) FC-PACO-RM: a parallel method for service composition optimal-selection in cloud manufacturing system. IEEE Trans Ind Inform 9(4):2023–2033

Tao F et al (2008) Resource service composition and its optimal-selection based on particle swarm optimization in manufacturing grid system. IEEE Trans ind Inform 4(4):315–327

Tian S et al. (2013) A discrete hybrid bees algorithm for service aggregation optimal selection in cloud manufacturing. Lecture Notes in Computer Science, 8206 LNCS, pp.110–117

Topcuoglu H et al (2005) Solving the uncapacitated hub location problem using genetic algorithms. Comput Oper Res 32(4):967–984

Valilai OF, Houshmand M (2013) A collaborative and integrated platform to support distributed manufacturing system using a service-oriented approach based on cloud computing paradigm. Robot Comput Integr Manuf 29(1):110–127

Wang SQ et al (2014) Research on the selection problem of machine tools in cloud manufacturing environment. Mater Sci Forum 800–801:649–653

Wei X, Liu H (2015) A cloud manufacturing resource allocation model based on ant colony optimization algorithm. Int J Grid Distrib Comput 8(1):55–66

Wu D et al (2015) Cloud-based design and manufacturing: a new paradigm in digital manufacturing and design innovation. Comput Aided Des 59:1–14

Wu D et al (2013) Cloud manufacturing: strategic vision and state-of-the-art. J Manuf Syst 32(4):564–579

Xiang F et al (2014) QoS and energy consumption aware service composition and optimal-selection based on Pareto group leader algorithm in cloud manufacturing system. CEJOR 22(4):663–685

Xiang F et al. (2016) The case-library method for service composition and optimal selection of big manufacturing data in cloud manufacturing system. Int J Adv Manuf Technol, pp.59–70

Xu X (2012) From cloud computing to cloud manufacturing. Robot Comput Integr Manuf 28(1):75–86

Xue X, Wang S, Lu B (2016) Manufacturing service composition method based on networked collaboration mode. J Netw Comput Appl 59(1):28–38

Yan-hua Z, Lei F, Zhi Y (2011) Optimization of cloud database route scheduling based on combination of genetic algorithm and ant colony algorithm. Procedia Eng 15:3341–3345

Yuan M et al. (2016) Multi-objective optimal scheduling of reconfigurable assembly line for cloud manufacturing. Optimization Methods & Software, Available at: https://doi.org/10556788.2016.1230210

Zhang L et al (2014) Cloud manufacturing: a new manufacturing paradigm. Enterp Inf Syst 8(2):167–187

Zheng H, Feng Y, Tan J (2016) A fuzzy QoS-aware resource service selection considering design preference in cloud manufacturing system. Int J Adv Manuf Technol 84(1–4):371–379

Zhou J & Yao X (2016a) A hybrid artificial bee colony algorithm for optimal selection of QoS-based cloud manufacturing service composition. Int J Adv Manuf Technol. Available at: https://doi.org/10.1007/s00170-016-9034-1

Zhou J & Yao X (2016b) DE-caABC: differential evolution enhanced context-aware artificial bee colony algorithm for service composition and optimal selection in cloud manufacturing. Int J Adv Manuf Technol, Available at: https://www.scopus.com/inward/record.uri?eid=2-s2.0-84975226461&partnerID=40&md5=5c0b4595703304b2dedcff7878ef034f

Zhu L, Li Q, He L (2012) Study on cloud computing resource scheduling strategy based on the ant colony optimization algorithm. IJCSI Int J Comput Sci Issues 9(5):54–58

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akbaripour, H., Houshmand, M., van Woensel, T. et al. Cloud manufacturing service selection optimization and scheduling with transportation considerations: mixed-integer programming models. Int J Adv Manuf Technol 95, 43–70 (2018). https://doi.org/10.1007/s00170-017-1167-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1167-3