Abstract

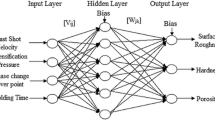

A visual breakout prediction method for mold monitoring is proposed based on temperatures measured by thermocouples in the mold combined with the use of computer vision technology. This mold temperature rate thermography allows the characteristics of abnormal temperature regions to be captured and extracted, including the rate of temperature change with time, the geometry, and propagation velocity. On the basis of these characteristics, a back-propagation (BP) neural network model is constructed to detect mold breakout. The weight and threshold values of the model are optimized using the Levenberg–Marquardt (LM) algorithm and a genetic algorithm (GA) through an iterative process of sample training and testing. The results show that the GA–LM–BP neural network model is better than both the traditional BP and the LM–BP models. This breakout prediction model has a higher accuracy rate (83.3 %) and a lower false-alarm rate (0.05 %). The GA–LM–BP model has also been compared with an actual BOPS used in continuous casting production. Meanwhile, it provides a way of detecting abnormalities visually for continuous casting process. The results of this work also provide a positive example of the application of intelligent monitoring and visualization methods to continuous casting.

Similar content being viewed by others

References

Lukyanov SI, Suspitsyn ES, Krasilnikov SS, Shvidchenko DV (2015) Intelligent system for prediction of liquid metal breakouts under a mold of slab continuous casting machines. Int J Adv Manuf Technol 79(9):1861–1868

Moon CH, Lee D, Moon SC, Park HD (2008) Re-start technology for reducing sticking-type breakout in thin slab caster. ISIJ Int 48(1):48–57

Thomas BG (2002) Modeling of the continuous casting of steel—past, present, and future. MMTB 33B:795–812

Watzinger J, Pesek A, Huebner N, Pillwax M, Lang O (2004) MoldExpert—operational experience and future development. Ironmak Steelmak 32(3):208–212

Qin X, Zhu CF, Yin YR, Dong XR (2010) Forecasting of molten steel breakouts for the slab continuous casters with hydraulic servo oscillation systems. Iron Steel 45(11):97–100

Wang XD, Yao M, Chen XF (2006) Development of prediction method for abnormalities in slab continuous casting using artificial neural network models. ISIJ Int 46(7):1047–1053

Ji C, Cai ZZ, Tao NB, Yang JL, Zhu MY (2012) Molten steel breakout prediction based on genetic algorithm and BP neural network in continuous casting process. In: Proceedings of 31st Chinese Control Conference (CCC), 25–27 July 2012, Hefei. IEEE, New York, pp 3402–3406.

Normanton AS, Hewitt PN, Hunter NS, Scoones D, Harris B (2004) Mould thermal monitoring: a window on the mould. Ironmak Steelmak 31(5):357–363

Yazid LDL, Salah B, Seghir BM, Jurgen B (2013) Adaptive support vector machine-based surface quality evaluation and temperature monitoring. Application to billet continuous casting process. Int J Adv Manuf Technol 67(9):2063–2073

Zhou J, Peng X, Qin Y (2009) A coupled thermal-mechanical analysis of a mold-billet system during continuous casting. Int J Adv Manuf Technol 42(5):421–428

He F, He DF, Xu AJ, Wang HB, Tian NY, Chang S, Bu G (2014) A method for plotting the on-line thermal map of a continuous casting mould. J Univ Sci Technol Beijing 36(7):952–958

Sohn I, Piccone TJ, Natarajan TT (2008) Detection of mold events using thermocouple measurements. Iron Steel Technol 5(1):44–50

Blazek KE, Saucedo IG (1900) Characterization of the formation, propagation and recovery of sticker/hanger type breakouts. ISIJ Int 30(6):435–443

Liu Y, Wang XD, Shi GQ, Yao M, Zhang XB, Ma H (2014) Mold sticking and its propagation behaviour during slab continuous casting. Iron Steel 49(2):31–35

Liu Y, Wang XD, Du FM, Kong LW, Yao M, Zhang XB (2015) Visual detection based on computer vision for sticker breakout in slab continuous casting. Ironmak Steelmak 42:417–423

Nielsen RH (1989) Theory of the backpropagation neural network. In :Proceedings of the International Joint Conference on Neural Networks, 18–22 June 1989, Washington, DC. IEEE, New York, Vol 1, pp 593–605

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Wang, X., Du, F. et al. Computer vision detection of mold breakout in slab continuous casting using an optimized neural network. Int J Adv Manuf Technol 88, 557–564 (2017). https://doi.org/10.1007/s00170-016-8792-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8792-0