Abstract

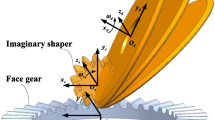

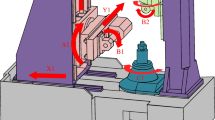

To accelerate face-gear engineering application, a precision grinding method for complex surface of aero face-gear is provided in this paper. Based on the principle of face-gear drive, the principle of face-gear grinding by disc wheel is analyzed, and the tooth surface equation of the face-gear is calculated with coordinate transformations. Taking the grinding needs into account, a special machine tool is developed, and movements control method of face-gear grinding by the disc wheel on the machine tool is proposed. To ensure the correct tooth profile of the disc wheel, the method of wheel dressing is provided and the optimum design methods of CNC cutter sites and step sizes selection are provided. To verify the feasibility of the grinding method for face-gear, the simulation of face-gear grinding by disc wheel is performed based on VERICUT software according to the grinding method. The experiments of face-gear grinding and the wheel dressing are carried out finally, and the results show that it is feasible for face-gear grinding using the involute disc wheel and the special machine tool.

Similar content being viewed by others

References

Litvin FL, Zhang Y, Wang JC, Bossler RB, Chen YJD (1992) Design and geometry of face-gear drives. J Mech Design 114(4):642–647

Litvin FL, Fuentes A, Zanzi C, Pontiggia M (2002) Design, generation, and stress analysis of two versions of geometry of face-gear drives. Mech Mach Theory 37(10):1179–1211

Litvin FL, Wang JC, Bossler RB, Bossler RB, Chen YJD, Heath G, Lewicki DG (1994) Application of face-gear drives in helicopter transmissions. J Mech Design 116(3):672–676

Heath GF, Filer RR, Tan J (2002) Development of face gear technology for industrial and aerospace power transmission. NASA/CR-2002-2011320

Handschuh RF, Lewicki DG, Bossler RB (1994) Experimental testing of prototype face gears for helicopter transmissions. J Aerosp Power 208(27):129–136

Dudas I, Bodzas S (2013) Production geometry analysis, modelling, and rapid prototyping production of manufacturing tool of spiroid face gear. Int J Adv Manuf Technol 66(1–4):271–181

Zhao N, Guo H, Fang ZD, Gao H (2010) Research on machining face-gear using a CNC hobbing machine. Adv Mat Research 97(101):3761–3764

Cai S, Chen GY, Zhou C, Deng H (2015) The mechanism and application of bronze-bond diamond grinding wheel pulsed laser dressing based on phase explosion. Int J Adv Manuf Technol 80(9–12):1641–1653

Rascalha A, Brandao LC, Ribeiro SLM (2013) Optimization of the dressing operation using load cells and the Taguchi method in the centerless grinding process. Int J Adv Manuf Technol 67(5–8):1103–1112

Radzevich SP, Krehel R (2012) Determination of the grinding wheel profile and its setup for use in finishing cylindrical gears with an evolvent profile. Int J Adv Manuf Technol 63(9–12):875–879

Yong HT, Chen DJ (2006) Online dressing of profile grinding wheels. Int J Adv Manuf Technol 27(9–10):883–888

Zhang KF, Yu YC, Wang WZ, Li H (2015) Experimental study on internal cylindrical grinding of bearing steel with electrolytic in-process dressing grinding. Int J Adv Manuf Technol 81(5–8):1175–1185

Litvin FL, Perez IG, Fuentes A, Vecchiato D, Hansen BD, Binney D (2005) Design, generation and stress analysis of face-gear drive with helical pinion. Comput Methods Appl Mech Engrg 194(36–38):3870–3901

Litvin FL, Fuentes A, Zanzi C (2002) Face-gear drive with spur involute pinion: geometry, generation by a worm, stress analysis. Comput Methods Appl Mech Engrg 191(25–26):2785–2813

Wang YZ, Wu CH, Ge XY, Zhang L (2009) Basal worm designing method of face-gear hob. J Beijing Univ Aeronaut Astronaut 35(2):166–169 (in Chinese)

Tang JY, Yin F, Chen XM (2013) The principle of profile modified face-gear grinding based on disc wheel. Mech Mach Theory 70(1):1–15

Guo H, Peng XQ, Zhao N, Zhang SY (2015) A CNC grinding method and envelope residual model for face gear. Int J Adv Manuf Technol 79(9–12):1689–1698

Peng XL, Fang ZD, Su JZ, Pei SS (2012) Theory analysis for application grinding disk in face gear grinding. J Aerosp Power 27(5):1159–1165 (in Chinese)

Deng XZ, Li GG, Wei BY, Deng J (2014) Face-milling spiral bevel gear tooth surfaces by application of 5-axis CNC machine tool. Int J Adv Manuf Technol 71(5–8):1049–1057

Chen ZZC, Wasif M (2015) A generic and theoretical approach to programming and post-processing for hypoid gear machining on multi-axis CNC face-milling machines. Int J Adv Manuf Technol 81(1–4):135–148

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Hou, L., Lan, Z. et al. Precision grinding technology for complex surface of aero face-gear. Int J Adv Manuf Technol 86, 1263–1272 (2016). https://doi.org/10.1007/s00170-015-8241-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8241-5