Abstract

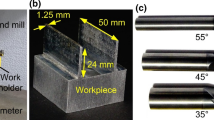

The process chain of product regeneration includes the removal of excess weld material, which is called re-contouring. Like all machining processes, re-contouring influences the surface integrity and therefore the functional performance of the regenerated parts. One important aspect of surface integrity is the surface topography, especially for blades in turbine engines due to the flow losses. This paper investigates the fundamental influence of cutting conditions, tool geometry and weld shape on the surface topography after 5-axis ball nose end milling of welded Ti-6Al-4V parts. It is shown by experiment and simulation that apart from the cutting parameters also the chipping of the cutting edge and the tool runout highly influence the surface topography. The size of the weld and the tool compliance primarily influence the tool deflection and the appearance of chatter vibrations.

Similar content being viewed by others

References

Bieler H (1997) Einkristalle reparieren (repair of monocrystals). Technical report, Sulzer AG, technical review

O’Neill WM (2001) Braze repair of gas turbine components: Retrospective, perspective, prospective. In: Proceedings of the 20th Conference (ASM International), HeatTreating 2000, pp 1040–1045

Brauny P, Hammerschmidt M, Malik M (1985) Repair of air-cooled turbine vanes of high-performance aircraft engines. In: Refurbishing of superalloy components for gas turbines

Bremer C (2007) Adaptive machining technology and data management for automated repair of complex turbine components with focus on blisk repair. In: 18th International Symposium on Airbreathing Engines (ISABE), Beijing

Brinksmeier E, Berger U, Janssen R (1998) Advanced mechatronic technology for turbine blades maintenance. In: Power Station Maintenance Profitability Through Reliability, 30 March - 1 April 1998

Eberlein A (2007) Phases of high-tech repair implementation. In: 18th International Symposium on Airbreathing Engines (ISABE), Beijing

Miglietti W, Summerside I (2010) Repair process technology development and experience for w501f row 1 hot gas path blades. In: Proceedings of ASME Turbo Expo: Power for Land, Sea and Air

Yilmaz O, Gindy N, Gao J (2010) A repair and overhaul methodology for aeroengine components. Robot Comput Integr Manuf 26:190–201

Denkena B, Nespor D, Böß V, Köhler J (2014) Residual stresses formation after re-contouring of welded ti-6al-4v parts by means of 5-axis ball nose end milling. CIRP J Manuf Sci Technol 7(4):347–360

Bons JP (2010), vol 132

Hohenstein S, Seume J (2013) Numerical investigation on the influence of anisotropic surface roughness on the skin friction. In: Proceedings of the European Turbomachinery Conference

Butler JJ (1997) Rough nozzle surfaces hurt turbine performance. Power Engineering (Barrington) 101:31–38

Lee JC, Kang HJ, Chu WS, Ahn SH (2007) Repair of damaged mold surface by cold-spray method. Annals of the CIRP 56(1):577–582

Gao J, Chen X, Yilmaz O, Gindy N (2008) An integrated adaptive repair solution for complex aerospace components through geometry reconstruction. Int J Adv Manuf Technol 36(11–12):1170–1179. Ball End Mill Machining of Turbine tips

Uhlmann E, Lypovka P (2013) Steigerung der werkzeugstandzeit und prozesssicherheit: Bei der schweinachbearbeitung durch angepasste frswerkzeuge. ZWF 108(7–8):504–508

Huang H, Gong ZM, Chen XQ, Zhou L (2003) Smart robotic system for 3d profile turbine vane airfoil repair. Int J Adv Manuf Technol 21:275–283

Möhring HC (2008) Reaktionsschnelle Instandsetzung von Formen mit einer transportablen hybridkinematischen Bearbeitungseinheit. PhD thesis, Leibniz Universität Hannover

Hieu NT (2007) Modellierung des Hochgeschwindigkeitsfräsens mit Kugelkopffräsern unter besonderer Berücksichtigung der Oberflächengüte. PhD thesis, Rheinisch-Westfälische Technische Hochschule Aachen (RWTH)

Inasaki I (2002) Initiatives of Precision Engineering at the Beginning of a Millennium. In: 10th International Conference on Precision Engineering (ICPE). Springer US, Yokohama, Japan, July 1820, 2001

Neugebauer R, Bouzakis K-D, Denkena B, Klocke F, Sterzing A, Tekkaya AE, Wertheim R (2011) Velocity effects in metal forming and machining processes. CIRP Ann 60:627– 650

Baptista R, Antune Simoes JF (2000) Three and five axes milling of sculptured surfaces. J Mater Process Technol 103(3):398– 403

Tönshoff HK, Hollmann F (2005) Hochgeschwindigkeitsspanen (High speed cutting). Wiley, Weinheim

Ulutan D, Özel T (2011) Machining induced surface integrity in titanium and nickel alloys: a review. Int J Mach Tools Manuf 51:250–280

Knobel PP (2000) Fräsen von Freiformflächen mit Schleifqualität. PhD thesis, Eidgenössische Technische Hochschule Zürich

Arizmendi M, Fernández J, López de Lacalle LN, Lamikiz A, Gil A, Sánchez JA, Campa FJ, Veiga F (2008) Model development for the prediction of surface topography generated by ball-end mills taking into account the tool parallel axis offset. experimental validation. CIRP Ann 57(1):101–104

Bouzakis K-D, Aichouh P, Efstathiou K (2003) Determination of the chip geometry, cutting force and roughness in free form surfaces finishing milling, with ball end tools. Int J Mach Tools Manuf 43:499–514

Buj-Corral I, Vivancos-Calvet J, Domínguez-Fernández A (2012) Surface topography in ball-end milling processes as a function of feed per tooth and radial depth of cut. Int J Mach Tools Manuf 53(0):151–159

Denkena B, Biermann D (2014) Cutting edge geometries. CIRP Ann 63(2):631–653

(2010) Deutsches Institut für Normung. Din en iso 4287: Geometrical product specifications (gps) - surface texture: Profile method - terms, definitions and surface texture

Quintana G, de Ciurana J, Ribatallada J (2010) Surface roughness generation and material removal rate in ball end milling operations. Mater Manuf Process 25(/6):386–398

Ozturk E, Tunc LT, Budak E (2009) Investigation of lead and tilt angle effects in 5-axis ball-end milling processes. Int J Mach Tools Manuf 49:1053–1062

Vakondios D, Kyratsis P, Yaldiz S, Antoniadis A (2012) Influence of milling strategy on the surface roughness in ball end milling of the aluminum alloy al7075-t6. Measurement 45:1480– 1488

Elbestawi MA, Ismail F, Yuen KM (1994) Surface topography characterization in finish milling. Int J Mach Tools Manuf 34(2):245–255

Chen JS, Huang YK, Chen MS (2005) A study of the surface scallop generating mechanism in the ball-end milling process. Int J Mach Tools Manuf 45(9):1077–1084

Liu N, Loftus M, Whitten A (2005) Surface finish visualisation in high speed, ball nose milling applications. Int J Mach Tools Manuf 45(10):1152–1161

Antoniadis A, Savakis C, Bilalis N, Balouktsis A (2003) Prediction of surface topomorphy and roughness in ball-end milling. Int J Adv Manuf Technol 21(12):965–971

Lavernhe S, Quinsat Y, Lartique C, Bown C (2014) Realistic simulation of surface defects in five-axis milling using the measured geometry of the tool. Int J Adv Manuf Technol 74:393– 401

Surmann T, Enk D (2007) Simulation of milling tool vibration trajectories along changing engagement conditions. Int J Mach Tools Manuf 47(9):1442–1448

Deutsches Institut für Normung. Din 4760: Form deviations: Concepts; classification system, 1982

Böß V, Nespor D, Samp A, Denkena B (2013) Numerical simulation of process forces during re-contouring of welded parts considering different material properties. CIRP J Manuf Sci Technol 6(3):167–174

Goeke S, Rausch S, Schumann S, Biermann D (2013) Charakterisierung funktionaler oberflächen durch die konfokale weißlichtmikroskopie (characterization of functional surfaces using white light confocal microscopy). Forum Schneidwerkzeug- und Schleiftechnik 2013:88–95

Kleppmann W (2011) Versuchsplanung Produkte und Prozesse optimieren (Design of Experiments: Improvements of Products and Processes). Hanser Verlag, 7., aktualisierte und erweiterte auflage edition

Budak E, Tunc LT (2010) Identification and modeling of process damping in turning and milling using a new approach. CIRP Ann 59(1):403–408

Tun LT, Budak E (2012) Effect of cutting conditions and tool geometry on process damping in machining. Int J Mach Tools Manuf 57(0):10–19

Altintas Y, Engin S (2001) Mechanics and dynamics of general milling cutters. part i: helical end mills. Int J Mach Tools Manuf 41:2195–2212

ASTM and American Society for Testing and Materials. Initial graphics exchange specification, 1997

Denkena B, Böß V (2009) Technological nc simulation for grinding and cutting processes using cuts

Salgado MA, López de Lacalle LN, Lamikiz A, Mu noa J, S’anchez JA (2005) Evaluation of the stiffness chain on the deflection of end-mills under cutting forces. Int J Mach Tools Manuf 45(6):727–739

Kim GM, Kim BH, Chu CN (2003) Estimation of cutter deflection and form error in ball-end milling processes. Int J Mach Tools Manuf 43(9):917–924

Toh CK (2004) Surface topography analysis in high speed finish milling inclined hardened steel. Precis Eng 28(4):386–398

Denkena B, Böß V, Nespor D, Gilge P, Hohenstein S, Seume J (2015) Prediction of the 3d surface topography after ball end milling and its influence on aerodynamics. Procedia Engineering 31:221–227. 15th CIRP Conference on Modelling of Machining Operations

Denkena B, Böß V, Nespor D, Samp A (2011) Kinematic and stochastic surface topography of machined tial6v4-parts by means of ball nose end milling. Procedia Engineering 19(0):81–87. 1st CIRP Conference on Surface Integrity (CSI)

Hahn Gerald J, Shapiro Samuel S (1994) Statistical Models in Engineering. Wiley

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nespor, D., Denkena, B., Grove, T. et al. Surface topography after re-contouring of welded Ti-6Al-4V parts by means of 5-axis ball nose end milling. Int J Adv Manuf Technol 85, 1585–1602 (2016). https://doi.org/10.1007/s00170-015-7885-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7885-5