Abstract

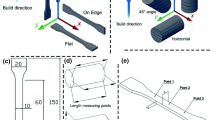

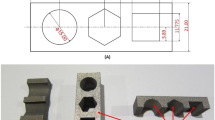

This study analyzed the effects of geometric size and grain size on the forming characteristics of a phosphor bronze thin sheet during micro bead forming processes. Specimens with different thicknesses were first heated at various temperatures for obtaining objective grain sizes. A tensile test was conducted to determine the mechanical properties of the specimens. A bead forming machine was used to conduct a bead forming test to measure and analyze curled angles, springback, and forming load; the measurement and analysis were conducted for investigating the geometric size and grain size effects in addition to the chamfer and lubrication effects during bead forming. The geometric size effect showed that the springback decreased with the thickness decreasing, and the grain size effect indicated that the springback increased with an increase in the grain size. Incorporating chamfers into the specimens enabled the specimens to be curled effectively, thus rendering chamfers the essential parameters for ensuring successful bead forming.

Similar content being viewed by others

References

Garcia-Romeu ML, Ciurana J, Ferrer I (2007) Springback determination of sheet metals in an air bending process based on an experimental work. J Mater Process Technol 191(1–3):174–177

Kalpekjian S (1998) Manufacturing engineering and technology. Addison-Wesley, Reading

Frank WW, Philip DH, Charles B, Gump JR, National Technical Committee Society of Manufacturing Engineers (1985) Die design handbook. McGraw-Hill, New York

Begeman Myron L, Amstead BH (1979) Manufacturing processes. Wiley, New York

Kwok SK, Lee WB (1995) The development of a machine vision system for adaptive bending of sheet metals. J Mater Process Technol 48(1–4):43–49

Pourpoghrat F, Chu E (1995) Prediction of springback and side-wall curl in 2D draw bending. J Mater Process Technol 50(1–4):361–374

Shu J, Hung C (1996) Finite element analysis and optimisation of springback reduction: the double-bent technique. Int J Mach Tools Manuf 36(4):423–434

Tseng AA, Chen TC, Jen KP, Kondetimmamhalli R, Murty YV (1995) Forming properties and springback evaluation of copper beryllium sheets. Metall Mater Trans A 26(8):2111–2121

Tomesani L (1998) Quality control in plane-strain bead-forming processes through the load–displacement curve. J Mater Process Technol 77(1):145–152

Geiger M, Vollertsen F, Kals R (1996) Fundamentals on the manufacturing of sheet metal micro parts. J Mater Process Technol 45(1):277–282

Raulea LV, Goijaerts AM, Govaert LE, Baaijens FPT (2001) Size effects in the processing of thin metal sheets. J Mater Process Technol 115(1):44–48

Michel JF, Picart P (2003) Size effects on the constitutive behaviour for brass in sheet metal forming. J Mater Process Technol 141(3):439–446

Tsai MC, Chen YA, Wu CF, Chen FK (2005) Size-effects in micro-metal sheet forming of unalloyed copper and brass. Adv Mater Res 6–8:705–712

Chen FK, Tsai JW (2006) A study of size effect in micro-forming with micro-hardness tests. J Mater Process Technol 177(1):146–149

Fulop T (2006) Size effects from grain statistics in ultra-thin metal sheets. J Mater Process Technol 174(1–3):233–238

Gau JT, Principe C, Wang J (2007) An experimental study on size effects on flow stress and formability of aluminum and brass for microforming. J Mater Process Technol 184:42–46

Chan WL, Fu MW (2012) Studies of the interactive effect of specimen and grain sizes on the plastic deformation behavior in microforming. Int J Adv Manuf Technol 62:989–1000

Liu WH, Wu Y, He JY, Nieh TG, Lu ZP (2013) Grain growth and the Hall–Petch relationship in a high-entropy FeCrNiCoMn alloy. Scr Mater 68(7):526–529

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, CC. Experimental study on formability of phosphor bronze thin sheet in micro bead forming process. Int J Adv Manuf Technol 84, 1897–1905 (2016). https://doi.org/10.1007/s00170-015-7860-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7860-1