Abstract

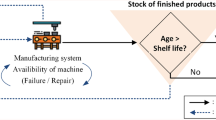

This article addresses the problem of joint production, maintenance, and emission control for an unreliable manufacturing system subject to degradation. The manufacturing system is composed of a production unit producing one product type. The production operations generate harmful emissions to the environment and may be sanctioned by an environmental penalty imposed by the relevant authorities under the emission cap approach. Due to degradation phenomena, the availability of the machine decreases and the emission rate increases continuously over time. This paper aims to propose a feedback strategy to simultaneously control production rate, emission rate, as well as maintenance rate in order to mitigate the effect of the degradation of the system. The objective is to minimize the total cost over an infinite horizon. In this article, three different control policies from the class of hedging point (HPP1, HPP2, HPP3) are proposed, analysed and compared. Each control policy is characterized by a production and/or maintenance strategy different from the others policies, with or without the consideration of the emission aspect in the structure of the policy. An experimental resolution approach based on experimental design, simulation, and response surface methodology is applied in order to determine the optimal control policy parameters. The results show that the proposed HPP3, which integrates the emission control in the production and maintenance strategy, gives a significant gain in terms of total cost compared to HPP1 and HPP2. In addition, we integrate a preventive maintenance strategy to HPP3 in order to investigate a more general case. To illustrate the robustness of the proposed policies, several sensitivity analyses are presented to show the effect of system parameters on the structures of each policy. This analysis allows defining an overhaul and a preventive maintenance zone from the interactions between the parameters of HPP3.

Similar content being viewed by others

References

Akella R, Kumar PR (1986) Optimal control of production rate in a failure-prone manufacturing system. IEEE Trans Autom Control AC-31(2):116–126

Bai SX, Elhafsi M (1997) Scheduling of an unreliable manufacturing system with non-resumable set-ups. Comput Ind Eng 32:909–925

Barlow RE, Hunter L (1960) Optimal preventive maintenance policies. Oper Res 8:90–100

Battini D, Persona A, Sgarbossa F (2013) A sustainable EOQ model: theoretical formulation and applications. Int J Prod Econ 149:145–153

Berthaut F, Gharbi A, Kenné JP, Boulet JF (2010) Improved joint preventive maintenance and hedging point policy. Int J Prod Econ 127(1):60–72

Berthaut F, Gharbi A, Dhouib K (2011) Joint modified block replacement and production/inventory control policy for a failure-prone manufacturing cell. Omega 39(6):642–654

Bloemhof-Ruwaard JM, Van Beek P, Hordjik L, Van Wassenhove LN (1995) Interactions between operational research and environmental management. Eur J Oper Res 85:229–243

Bouchery Y, Ghaffari A, Jemai Z, Dallery Y (2012) Including sustainability criteria into inventory models. Eur J Oper Res 222(2):229–240

Caramanis M, Sharifnia A (1991) Near optimal manufacturing flow controller design. Int J Flex Manuf Syst 3:321–336

Chelbi A, Ait-kadi D (2004) Analysis of a production/ inventory system with randomly failing production unit submitted to regular preventive maintenance. Eur J Oper Res 156:712–718

Chen C, Monahan GE (2010) Environmental safety stock: the impacts of regulatory and voluntary control policies on production planning, inventory control, and environmental performance. Eur J Oper Res 207(3):1280–1292

Chouikhi H, Dellagi S, Rezg N (2012) Development and optimisation of a maintenance policy under environmental constraints. Int J Prod Res 50(13):3612–3620

Dehayem NFI, Kenne JP, Gharbi A (2009) Hierarchical decision making in production and repair/replacement planning with imperfect repairs under uncertainties. Eur J Oper Res 198:173–189

Dehayem NFI, Kenné JP, Gharbi A (2011) Production planning and repair/replacement switching policy for deteriorating manufacturing systems. Int J Adv Manuf Technol 57:827–840

Dhouib K, Gharbi A, Ayed S (2008) Availability and throughput of unreliable, unbuffered production lines with non-homogeneous deterministic processing time. Int J Prod Res 46(20):5651–5677

Dhouib K, Gharbi A, Ben Aziza MN (2012) Joint optimal production control/preventive maintenance policy for imperfect process manufacturing cell. Int J Prod Econ 137(1):126–136

Dobos I (1998) Production-inventory control under environmental constraints. Int J Prod Econ 56:123–131

Dobos I (1999) Production strategies under environmental constraints in an Arrow-Karlin model. Int J Prod Econ 59:337–340

Dobos I (2001) Production strategies under environmental constraints: continuous-time model with concave costs. Int J Prod Econ 71:323–330

Fernandes FCF, Azeka F, Barreto MCM, Filho MG (2009) Identifying production planning and control top authors: analysis of a survey. Int J Bus Innov Res 3(5):461–478

Gharbi A, Hajji A, Dhouib K (2011) Production rate control of an unreliable manufacturing cell with adjustable capacity. Int J Prod Res 49(21):6539–6557

Gharbi A, Kenne J-P, Hajji A (2006) Operational level-based policies in production rate control of unreliable manufacturing systems with setups. Int J Prod Res 44(3):545–567

Hajji A, Gharbi A, Kenne JP, Pellerin R (2011) Production control and replenishment strategy with multiple suppliers. Eur J Oper Res 208(1):67–74

Hajji A, Gharbi A, Kenne JP (2009) Joint replenishment and manufacturing activities control in two stages unreliable supply chain. Int J Prod Res 47(12):3231–3251

Kimemia JG, Gershwin SB (1983) An algorithm for the computer control production in flexible manufacturing systems. IIE Trans 15(4):353–362

Lam Y, Zhu LX, Chan JSK, Liu Q (2004) Analysis of data from a series of events by a geometric process model. Acta Math Applicatae 20:263–282

Lavoie P, Gharbi A, Kenne J-P (2010) A comparative study of pull control mechanisms for unreliable homogenous transfer lines. Int J Prod Econ 124(1):241–251

Li S (2013) Optimal control of the production–inventory system with deteriorating items and tradable emission permits. Int J Syst Sci. doi:10.1080/00207721.2013.770103

Li S (2014) Optimal control of production-maintenance system with deteriorating items emission tax and pollution R&D investment. Int J Prod Res 52(60):1787–1807

Li S, Gu M (2012) The effect of emission permit trading with banking on firm’s production–inventory strategies. Int J Prod Econ 137:304–308

Love CE, Zhang ZG, Zitron MA, Guo R (2000) Discrete semi-Markov decision model to determine the optimal repair/replacement policy under general repairs. Eur J Oper Res 125(2):398–409

Mckay KN (2003) Historical survey of manufacturing control practices from a production research perspective. Int J Prod Res 41(3):411–426

Montgomery DC (2005) Design and analysis of experiments. John Wiley & Sons, New York

Parlar M, Perry D (1995) Analysis of a (Q, r, T) inventory policy with deterministic and random yields when future supply is uncertain. Eur J Oper Res 84:431–443

Przepiórski J (2006) Activated carbon surfaces in environmental remediation. Interface Sci Technol 7:421–474

Radhoui M, Rezg N, Chelbi A (2009) Integrated model of preventive maintenance, quality control and buffer sizing for unreliable and imperfect production systems. Int J Prod Res 47(2):389–402

Rivera-Gómez H, Gharbi A, Kenné JP (2013) Joint production and major maintenance planning policy of a manufacturing system with deteriorating quality. Int J Prod Econ 146(2):575–587

Rivera-Gomez H, Gharbi A, Kenné JP (2013) Joint control of production, overhaul, and preventive maintenance for a production system subject to quality and reliability deteriorations. Int J Adv Manuf Technol 69(9–12):2111–2130

Sethi SP, Zhang Q (1999) Average-cost optimal policies for an unreliable flexible multiproduct machine. Int J Flex Manuf Syst 11:147–157

Zhang JJ, Nie TF, Du SF (2011) Optimal emission-dependent production policy with stochastic demand. Int J Soc Syst Sci 3(1):21–39

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ben-Salem, A., Gharbi, A. & Hajji, A. Environmental issue in an alternative production–maintenance control for unreliable manufacturing system subject to degradation. Int J Adv Manuf Technol 77, 383–398 (2015). https://doi.org/10.1007/s00170-014-6454-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6454-7