Abstract

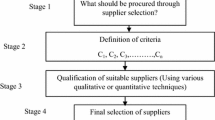

Purchase allocation is a multi criteria decision making (MCDM) problem. Multitude of qualitative and quantitative factors is involved in the multiple sourcing decisions. Analytic hierarchy process (AHP) has widely been used to find out the relative rankings of suppliers. AHP can be combined with regular supplier quantitative audit process. In classical AHP, decision maker (DM) has to pair wise compare suppliers for each factor, whereas the proposed audit based simplified AHP will remove the complexity of comparison. Quarterly audit-based AHP rankings and supplier performance probability products can be used in place of revenues in the backward recursive resource allocation knapsack model. This combined model will decompose purchase allocation problem into different stages and combine one supplier at each stage and provide the optimum and feasible solution in the end. Solution at each stage is also a feasible option. This model is only applicable when the total order quantity and the capacity of all suppliers are integer multiples of economic or minimum order quantity. This integrated model thus provides number of orders/supplier.

Similar content being viewed by others

References

Burke GJ, Carrillo JE, Vakharia AJ (2007) Production, manufacturing and logistics single versus multiple supplier sourcing strategies. Eur J Oper Res 182:95–112

Berger PD, Gerstenfeld A, Zeng AZ (2004) How many suppliers are best? A decision-analysis approach. Omega (Int J Management Science) 32:9–15

Saaty TL (1980) The analytic hierarchy process (AHP). McGraw-Hill, New York

Vaidya OS, Kumar S (2006) Analytic hierarchy process: an overview of applications. Eur J Oper Res 169:1–29

Burke GJ, Geunes J, Romeijn HE, Vakharia A (2008) Allocating procurement to capacitated suppliers with concave quantity discounts. Oper Res Lett 36:103–109

Ho W (2008) Integrated analytic hierarchy process and its applications—a literature review. Eur J Oper Res 186:211–228

Ghodsypour SH, O’Brien C (1998) A decision support system for supplier selection using an integrated analytic hierarchy process and linear programming. Int J Prod Econ 56–57:199–212

Yu JR, Tsai CC (2008) A decision framework for supplier rating and purchase allocation: a case in the semiconductor industry. Comput Ind Eng 55:634–646

Taha HA, Operations research: an introduction eighth edition, chapter 10 Deterministic Dynamic Programming (405-408) Pearson Education, Inc (2007)

Burke GJ, Geunes J, Romeijn HE, Vakharia A (2008) Allocating procurement to capacitated suppliers with concave quantity discounts. Oper Res Lett 36:103–109

Faez F, Ghodsypour SH, O’Brien C (2009) Vendor selection and order allocation using an integrated fuzzy case-based reasoning and mathematical programming model. Int J Prod Econ 121:395–408

Talluri S, Narasimhan R (2004) O.R. applications, a methodology for strategic sourcing. Eur J Oper Res 154:236–250

Sanayei A, Mousavi SF, Abdi MR, Mohaghar A (2008) An integrated group decision-making process for supplier selection and order allocation using multi-attribute utility theory and linear programming. J Franklin Inst 345:731–747

Bichler B, Kalagnanam J (2005) Configurable offers and winner determination in multi-attribute auctions. Eur J Oper Res 160:380–394

Ozpeynirci S, Azizo MG (2009) Bounding approaches for operation assignment and capacity allocation problem in flexible manufacturing systems. Comput Oper Res 36:2531–2540

Michel S, Perrot N, Vanderbeck F (2009) Discrete optimization knapsack problems with setups. Eur J Oper Res 196:909–918

Sbihi A (2010) Discrete optimization a cooperative local search-based algorithm for the multiple-scenario max–min knapsack problem. Eur J Oper Res 202:339–346

Hackman ST, Rosenblatt MJ, Olin JM (1990) Allocating items to an automated storage and retrieval system. IIE Trans 22(1):7–14

Gu J, Goetschalckx M, McGinnis L (2007) F, Research on warehouse operation: a comprehensive review. Eur J Oper Res 177:1–21

Pisinger D (2005) Where are the hard knapsack problems? Comput Oper Res 32:2271–2284

Saaty TL, Alexander JM (1981) Thinking with models, mathematical models in the physical, biological and social sciences, chapter 8. Pergamon Press, London

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, S., Dubey, D. Multiple sourcing decisions using integrated AHP and knapsack model: a case on carton sourcing. Int J Adv Manuf Technol 51, 1171–1178 (2010). https://doi.org/10.1007/s00170-010-2673-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-2673-8