Abstract

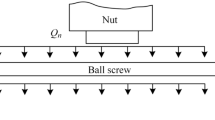

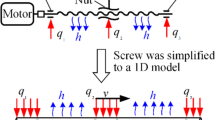

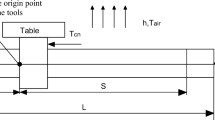

Empirical modeling of machine tools on thermal error has been widely researched, which can compensate for thermal error to some extent but not suitable for thermal dynamic error produced by dynamics heat sources. Ball screw is the main member of feed system of machine tool. On the basis of the theory of heat transfer, thermoelastic phenomenon of unidimensional heat transferring of the ball screw influenced by changeable heat sources is analyzed. A method to establish a dynamics characteristics model of thermal deformation of the ball screw based on least square system identification theory is put forward. Through simulation data, correctness and validity of modeling approach is proven. By this method, modeling of thermal error of X-axis of feed system of DM4600 vertical miller is established which has good identification effect.

Similar content being viewed by others

References

Wu N, Hu R (2004) Influence of rigidity of feed system with ball screw in NC lathe on positioning precision. Chin Eng Sci 9:46–49

Zou X (1997) Position precision of NC machine tool’s feed system. Journal of Nanchang University (Engineering & Technology) 12:85–88

Choi JK, Lee DG (1998) Thermal characteristics of the spindle bearing system with a gear located on the bearing span. Int J Mach Tools Manuf 38:1017–1030. doi:10.1016/S0890-6955(97)00075-8

Lee SK, Yoo JH, Yang MS (2003) Effect of thermal deformation on machine tool slide guide motion. Tribology 36:41–47

Kim SK, Cho DW (1997) Real time estimation of temperature distribution in a ball-screw system. Int J Mach Tools Manuf 37(4):451–464. doi:10.1016/S0890-6955(96)00036-3

Yuan J, Ni J (1998) The real-time error compensation technique for CNC machining systems. Mechatronics 8:359–380. doi:10.1016/S0957-4158(97)00062-7

Yang H, Ni J (2005) Adaptive model estimation of machine-tool thermal errors based on recursive dynamic modeling strategy. Int J Mach Tools Manuf 45:1–11. doi:10.1016/j.ijmachtools.2004.06.023

Li YX, Yang JG, Gelvis T, Li YY (2008) Optimization of measuring points for machine tool thermal error based on grey system theory. Int J Adv Manuf Technol 35(7–8):745–750. doi:10.1007/s00170-006-0751-8

Chen JS, Chiou G (1995) Quick testing and moding of thermally induced errors of CNC machine tools. Int J Mach Tools Manuf 35:1063–1074. doi:10.1016/0890-6955(94)00101-O

Srivastava AK, Veldhuis SC (1995) Modelling geometric and thermal errors in a five-axis CNC machine tool. Int J Mach Tools Manuf 35:1321–1337. doi:10.1016/0890-6955(94)00048-O

Huang S-C (1995) Analysis of a model to forecast thermal deformation of ball screw feed drive systems. Int J Mach Tools Manuf 35:1099–1104. doi:10.1016/0890-6955(95)90404-A

Wu CH, Kung YT (2003) Thermal analysis for the feed drive system of a CNC machine center. Int J Mach Tools Manuf 43:1001–1528. doi:10.1016/S0890-6955(03)00093-2

Song X, Wang Z, Liu X (2006) The thermal deformation control during precision ball screw grinding. Manuf Technol Mach Tool 1:59–61

Zhaonian C, Chen Z (1981) The basic of machine tool’s thermal characteristic. Mechanical Industry Press, Beijing

Li H, Yung SC (2004) Analysis of bearing conguration effects on high speed spindles using an integrated dynamic thermo-mechanical spindle model. Int J Mach Tools Manuf 44:347–364. doi:10.1016/j.ijmachtools.2003.10.011

Fu J, Chen Z (2004) Research on modeling dynamic errors of precision machine based on fuzzy logic and artificial neural network. Journal of Zhejiang University 6:32–36

Yang H, Ni J (2005) Dynamic neural network modeling for nonlinear, nonstationary machine tool thermally induced error. Int J Mach Tools Manuf 45:455–465. doi:10.1016/j.ijmachtools.2004.09.004

Yang H, Ni J (2003) Dynamic modeling for machine tool thermal error compensation. ASME Trans J Manuf Sci Eng 125:245–254. doi:10.1115/1.1557296

Yu C (1982) Heat transfer and numerical analyse. Press of Qinghua University, Beijing

Yu Z, Lu L (1995) Heat transferring. High Educ Press 5:14–31

Ljung L (1999) System identification—theory for user. Tsinghua University Press, Beijing

Hou Y, Wang M, Wang L (2004) System identification and Matlab simulating. Scientific Press, Beijing

Zhang C, Fan B, Gui D (2005) ANSYS8.0. Thermal Analytics Railroad Industry Press, Beijing ISBN:7-113-06537-6

Lo C-H, Yuan J, Ni J (1999) Optimal temperature variable selection by grouping approach for thermal error modeling and compensation. Int J Mach Tools Manuf 39:1383–1396. doi:10.1016/S0890-6955(99)00009-7

Yang J, Yuan J, Ni J (1999) Thermal error mode analysis and robust modeling for error compensation on a CNC turning center. Int J Mach Tools Manuf 39:1367–1381. doi:10.1016/S0890-6955(99)00008-5

Ramesh R, Mannan MA, Poo AN (2002) Support vector machines model for classification of thermal error in machine tools. Int J Adv Manuf Technol 20(2):114–120. doi:10.1007/s001700200132

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Junyong, X., Youmin, H., Bo, W. et al. Research on thermal dynamics characteristics and modeling approach of ball screw. Int J Adv Manuf Technol 43, 421–430 (2009). https://doi.org/10.1007/s00170-008-1723-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-008-1723-y