Abstract

Results of a study of the effects of process parameters on the quality achieved during laser cutting of alumina are presented. The effects of the interaction time, irradiance and assist gas pressure on the quality output variables such as striation angle, striation wavelength and the distance of clearly defined striations are studied. A physical interpretation of the correlation matrix and regression models develop is given. For the range of operation condition tested, it was observed that the inclination of the striation is most affected by interaction time, with assist gas pressure having a secondary effect and irradiance playing a minor role. Striation wavelength and upper and lower striation lengths are most influenced by interaction time and irradiance, both causing longer wavelengths.

Similar content being viewed by others

References

Arata Y et al (1979) Dynamic behaviour in laser gas cutting of mild steel. Transactions of JWRI 8(2):15–26

Powell J (1993) CO2 laser cutting. Springer, Berlin Heidelberg New York

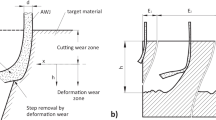

Schuocker D (1986) Dynamic phenomena in laser cutting. Appl Phys, B Photophys Laser Chem 40:9–14

Olsen FO (1994) Fundamental mechanisms of cutting front formation in laser cutting. in laser materials processing: industrial and microelectronics applications. SPIE 2270:402–413

Sforza P, Santacesaria V (1994) CO2 laser cutting: analytical dependence of the roughness of the cut edge on the experimental parameters and process monitoring. in laser materials processing: industrial and microelectronics applications. SPIE 2207:836–847

Tsai M-J, Weng C-I (1993) Linear stability analysis of molten flow in laser cutting. J Phys, D Appl Phys 26(5):719–727

Vicanek M, Simon G (1987) Momentum and heat transfer of an inert gas jet to the melt in laser cutting. J Phys, D Appl Phys 20(9):1191–1196

Makashev NK et al (1994) Gas hydrodynamics of CW laser cutting of metals in inert gas. in Russia National Conference: industrial lasers and laser material processing. SPIE 2257:2–9

King TG, Powell J (1986) Laser-cut mild steel - factors affecting edge quality. Wear 109(1–4):135–144

Rajaram N, Sheikh-Ahmad J, Cheraghi SH (2003) CO2 laser cut quality of 4130 steel. Int J Mach Tools Manuf 43(4):351–358

Yilbas BS (2004) Laser cutting quality assessment and thermal efficiency analysis. J Mater Process Technol 155–156:2106–2115

Di Pietro P, Yao YL (1995) A new technique to characterize and predict laser cut striations. Int J Mach Tools Manuf 35(7):993–1002

Krzanowski WJ Principles pf multivariate analysis: a user’s perspective. Oxford statistical science series; 3. 1988, Oxford: Clarendon

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wee, L.M., Crouse, P.L. & Li, L. A statistical analysis of striation formation during laser cutting of ceramics. Int J Adv Manuf Technol 36, 699–706 (2008). https://doi.org/10.1007/s00170-006-0888-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0888-5