Abstract

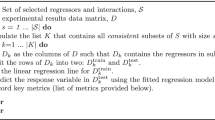

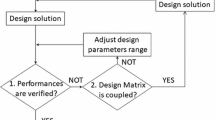

Variation in product performance can be seen as a design failure. The fundamental principle of robust design proposed by Taguchi is to improve the quality of a product by minimizing the effect of causes of variation, without totally eliminating the causes. A method of robust design is briefly explained and its application is demonstrated with the help of a case study from Roots Industries Ltd., Coimbatore. This paper describes how the inherent modeling of product and process requirements in key characteristics (KCs) can be used to express and capture the product design intent. KCs are those features which significantly affect product function and performance, or occur when there is variation. A prototype software program (VRM Tool) was developed to house all the critical design data for process optimization and its eventual reuse. We establish a systematic process of identifying, assessing and mitigating risk in the early stage of design for a Windtone class of automobile electric horn, using robust design concept. The results suggest that the proposed robust design method is an efficient, disciplined approach that can assist a product delivery team in designing for a better functional performance and improved reliability of the entire system .

Similar content being viewed by others

References

Taguchi G (1987) System of experiment design, Volume 1 and 2. In: Clausing D (ed) System of experiment design. UNIPUB/Kraus, New York

Phade MS (1989) Quality Engineering using robust design. Prentice-Hall, New York

Ross PJ (1988) Taguchi techniques for quality engineering. McGraw-Hill, New York

Barker TB (1986) Quality engineering by design: Taguchi’s philosophy. Qual Prog 1:33–42

Bendell T (ed) (1989) Taguchi methods, first European conference papers. Elsevier, Amsterdam

Taguchi G (1986) Introduction to quality engineering. Asian Productivity Organization, UNIPUB, New York

Park SH (1996) Robust design and analysis for quality Engineering. Chapman and Hall, London

Kacker RN (1985) Off-line quality control, parameter design and the Taguchi method. J Qual Technol 17(4):176–188

Wu Y (1989) Taguchi methods, case studies from the US and Europe. ASI Press, Dearborn, Michigan

Chen W (1996) A procedure for robust design: minimizing variations caused by noise factors and control factors. ASME J Mech Des 118:478–485

Thornton AC (1998) Variation risk management in industry. MIT Press, Cambridge, MA

Thornton AC (1999) Variation risk management using modeling and simulation. ASME J Mech Des 121:297–304

Ertan B (1998) Analysis of key characteristic methods and enablers used in various risk management. Dissertation, MIT, Cambridge, MA

Chanbonneau HC, Webster GL (1978) Industrial quality control. Prentice-Hall, New York

Kane VE (1986) Process capability indices. J Qual Technol 18(1):41–52

Bissell AF (1990) How reliable is your capability index? Appl Stat 39:331–340

Boyles RA (1991) The Taguchi capability index. J Qual Technol 23:17–26

Chen JP, Tong LI (2003) Bootstrap confidence interval of the difference between to process capability indices. J Adv Manuf Technol 21:249–256

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nataraj, M., Arunachalam, V. & Ranganathan, G. Using risk analysis and Taguchi’s method to find optimal conditions of design parameters: a case study. Int J Adv Manuf Technol 27, 445–454 (2006). https://doi.org/10.1007/s00170-004-2400-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-004-2400-4