Abstract

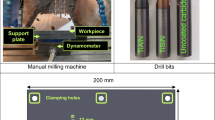

As a result of the need to automate assembly in the aircraft industry, along with economic and ecological reasons, industry and research institutions have been pushed to develop dry drilling for aluminium alloys to eliminate the need for cooling fluids. The main difficulties in dry drilling are accelerated tool wear due to workpiece material adhesion on the tool and the formation of bigger-sized burrs. This paper describes an experimental research study on machinability in the dry drilling of aluminium alloys and on the potential of the new design of tools and coatings. Dry drilling tests were performed using uncoated drills and two different coatings produced by means of an arc evaporation PVD process. Experiments consisted of machining with a 10-mm diameter three-edged drill to produce 25-mm deep holes. Tool wear evolution and burr size were analysed, as well as the impact of the process parameters on torque, power, feed force and tool temperature.

Similar content being viewed by others

References

Jimenez M, De Mingo D, Del Real JC, Sandes V (2001) Taladrado y roscado de alta velocidad. Ediciones Técnicas IZARO, Bilbao

Klocke F, Eisenblätter G (1997) Dry cutting. Annals of the CIRP 46(2):519–526

Kalhöfer E (1998) Dry machining – technology and requirements to the machine tool. In: Proceedings of the International Seminar on Improving machine-tool performance, Michelena artes gráficas, San Sebastian, pp 633–641

Lenz E, Katz Z, Ber A (1976) Investigations on the flank wear of cemented carbide tools. ASME Trans J Eng Ind 98 (1):246–250

Hann DM, Batzer SA, Olson WW, Sutherland JW (1997) An experimental study of cutting fluids effect in drilling. J Mater Process Technol 71:305–313

Tönshoff HK, Karpuschewski B, Mohlfeld A (1998) Influence of drill tool design on cutting performance in dry machining. In: Proceedings of the International Seminar on improving machine-tool performance, San Sebastian, pp 677–687

Celaya A, López de Lacalle LN, BravoU, Fraile S, Girot F (2002) Análisis teórico y experimental del efecto del lubricante micropulverizado en el fresado a alta velocidad. In: Proceedings of XIV Congreso de máquinas-herramienta y tecnologías de fabricación, San Sebastián

Derflinger V, Brandle H, Zimmermann H (1999) New hard/lubricant coating for dry machining. Surface Coatings Technol 113:286–292

Zelinski P (2000) In dry machining, two coatings may be better than one. Available at: http://www.mmsonline.com/articles/0100rt3.html

Klocke F, Eisemblatter G, Lung D (1998). Dry cutting-fundamentals, limitations, vistas. In: Proceedings of the International Seminar on Improving machine-tool performance, Michelena artes gráficas, San Sebastian, pp 621–632

Klocker F, Eisenblätter G (1997) Machinability investigation of the drilling process using minimal cooling lubrication techniques. In: German Academic Society for Production Engineering (ed) Production Engineering, Vol IV/1, pp 19–24

Kelly JF, Cotterell MG (2002) Minimal lubrication machining of aluminium alloys. J Mater Process Technol 120:327–334

Bittes G, Aubry 0, Auffret A, Fantin JP, Laur R, Roger C (1997) High-speed drilling. In: Proceedings of French and German Conference on High-Speed Machining, June 1997, Metz

Nouari M, List G, Girot F, Coupard D (2003) Experimental analysis and optimisation of tool wear in dry machining of aluminium alloys. Wear 255:1359–1368

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rivero, A., Aramendi, G., Herranz, S. et al. An experimental investigation of the effect of coatings and cutting parameters on the dry drilling performance of aluminium alloys. Int J Adv Manuf Technol 28, 1–11 (2006). https://doi.org/10.1007/s00170-004-2349-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-004-2349-3