Abstract

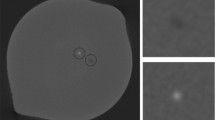

Ultrasonic C-mode scanning acoustic microscopy (C-SAM) is widely used in the semiconductor industry for reliability testing and product inspection due to its ability to nondestructively detect defects in IC packaging. However, image interpretation and defect identification depend largely on the experience of operators, and there is no defect recognition system; this is partly due to current recognition systems, which are based on computer vision algorithms and are not robust for C-SAM images. A new robust defect recognition system and its application to C-SAM images are described in this paper. The iconic domain of two-dimensional C-SAM grey-level image analysis based on the non-linear Mumford-Shah model is used, and defect recognition is achieved through the use of Support Vector Machines (SVMs). The system is verified through experiments on a sequence of C-SAM images corrupted by synthetically generated noise, bias and different shape. The remarkable defect recognition rates achieved indicate that Support Vector Machines (SVMs) are suitable for IC package defect identification.

Similar content being viewed by others

References

Moore TM (1989) Identification of package defects in plastic-packaged surface mount ICs by scanning acoustic microscopy. In: Proceedings of the international symposium on testing and failure analysis (ISFTA’89), location, day month 1989, pp 61–67

Rao AR (1996) Future directions in industrial machine vision: a case study of semiconductor manufacturing applications. Image Vision Comput 14:3–19

Dom BE, Brecher V (1995) Recent advances in the automatic inspection of integrated circuits for pattern defects. Mach Vision Appl 8:5–19

Zhou H, Kassim AA (1998) A fast algorithm for detecting die extrusion defects in IC packages. Mach Vision Appl 11:37–41

Dinesh P, Teoh KK (1989) An intelligent vision system for inspection of packaged ICs. In: TENCON ’89, Fourth IEEE region 10 international conference, pp 1003-1006

Peng J, Bhanu B (1998) Closed-loop object recognition using reinforcement learning. IEEE Trans Patt Anal Mach Intell 20:139–154

Vapnik VN (1995) The nature of statistical learning theory. Springer, Berlin Heidelberg New York

Yun TS, Sim KJ, Kim HJ (2000) Support vector machine-based inspection of solder joints using circular illumination. Electron Lett 36(11):949–951

Jain R, Kasturi R, Schunk BG (1995) Machine vision. McGraw-Hill, New York

Hu MK (1962) Visual pattern recognition by moment invariants. IRE Trans Inf Theory volume:179–187

Chang C-C, http://www.csie.ntu.edu.tw/∼cjlin/libsvm/

Jain AK, Chanderasekaran B (1982) Dimensionality and sample size considerations in pattern recognition practice. In: Krithananiah PR, Kanal N (eds) Handbook of statistics, vol 2. North-Holland, Amsterdam, pp 835–855

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Guo, N., Du, H. et al. Automated defect recognition of C-SAM images in IC packaging using Support Vector Machines. Int J Adv Manuf Technol 25, 1191–1196 (2005). https://doi.org/10.1007/s00170-003-1942-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-1942-1