Abstract

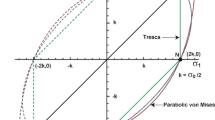

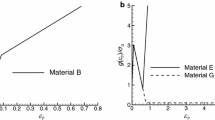

The stress field near voids (or holes, or pores) essentially contributes to the fracture process in metallic and nonmetallic materials. In contrast to strains, it is practically impossible to measure stresses experimentally. Therefore, accurate theoretical methods are required to calculate the stress field near a void of arbitrary shape. The present paper develops such a method for the Mohr–Coulomb yield criterion under plane strain conditions. The boundary value problem is a free surface boundary value problem. The boundary conditions on the void contour result in the Cauchy problem for a hyperbolic system of equations. Therefore, the solution in a plastic region adjacent to the void is independent of other boundary conditions. It is required to evaluate one ordinary integral numerically for calculating the stresses at any point of the plastic region. The general solution applies to determining the stress field near two families of void contours. One family consists of contours with the same aspect ratio, including an ellipse as a particular contour. The other family consists of equal-areal voids, including a circle as a particular contour. This choice of the contour families reveals the void shape’s effect on the stress field. The effect of the internal friction angle of the stress field is also discussed.

Similar content being viewed by others

References

Feng, C., Cui, Z., Shang, X., Liu, M.: An evolution model for elliptic-cylindrical void in viscous materials considering the evolvements of void shape and orientation. Mech. Mater. 112, 101–113 (2017). https://doi.org/10.1016/j.mechmat.2017.06.002

Barrioz, P., Hure, J., Tanguy, B.: On void shape and distribution effects on void coalescence. ASME. J. Appl. Mech. 86, 011006 (2019). https://doi.org/10.1115/1.4041548

Gao, X., Wang, T., Kim, J.: On ductile fracture initiation toughness: effects of void volume fraction, void shape and void distribution. Int. J. Solids Struct. 42, 5097–5117 (2005). https://doi.org/10.1016/j.ijsolstr.2005.02.028

Wang, L., Yu, W., Shen, S.: Fracture of \(\beta \)-SiC bulk with a void of different shapes under different loading modes. Eng. Fract. Mech. 181, 29–37 (2017). https://doi.org/10.1016/j.engfracmech.2017.06.020

Li, W., Jing, Y., Zhou, T., Xing, G.: A new ductile fracture model for structural metals considering effects of stress state, strain hardening and micro-void shape. Thin-Walled Struct. 176, 109280 (2022). https://doi.org/10.1016/j.tws.2022.109280

Xie, J., Rui, Z., Liu, T., Zhou, C., Jia, L.J.: Effect of initial void shape on void growth of structural steels based on micromechanical RVE models. J. Mater. Civ. Eng. 34, 04022010 (2022). https://doi.org/10.1061/(ASCE)MT.1943-5533.0004150

Thomason, P.F.: Riemann-integral solutions for the plastic slip-line fields around elliptical holes. ASME. J. Appl. Mech. 45, 678–679 (1978). https://doi.org/10.1115/1.3424381

Wu, H., Zhao, G., Liang, W.: Mechanical properties and fracture characteristics of pre-holed rocks subjected to uniaxial loading: a comparative analysis of five hole shapes. Theor. Appl. Fract. Mech. 105, 102433 (2020). https://doi.org/10.1016/j.tafmec.2019.102433

Zhaofeng, C., Yonghui, S.: Failure mechanical characteristics of rock with different hole shapes. Geotech. Geol. Eng. 39, 3437–3447 (2021). https://doi.org/10.1007/s10706-021-01702-5

Tan, L., Ren, T., Dou, L., Yang, X., Qiao, M., Peng, H.: Analytical stress solution and mechanical properties for rock mass containing a hole with complex shape. Theor. Appl. Fract. Mech. 114, 103002 (2021). https://doi.org/10.1016/j.tafmec.2021.103002

Amini, A., Arwade, S., Clouston, P., Rattanaserikiat, S.: Characterization and probabilistic modeling of the mesostructure of parallel strand lumber. J. Mater. Civ. Eng. 27, 04014179 (2014). https://doi.org/10.1061/(ASCE)MT.1943-5533.0001116

Amini, A., Arwade, S., Clouston, P.: Modeling the effect of void shapes on the compressive behavior of parallel-strand lumber. J. Mater. Civ. Eng. 29, 04017129 (2017). https://doi.org/10.1061/(ASCE)MT.1943-5533.0001980

Eliasson, S., Karlsson Hagnell, M., Wennhage, P., Barsoum, Z.: An experimentally based micromechanical framework exploring effects of void shape on macromechanical properties. Materials 15, 4361 (2022). https://doi.org/10.3390/ma15124361

Shimizu, S., Sato, M., Koyanagi, J., Suemasu, H., Kogo, Y.: Numerical simulation of compressive failure of carbon-fiber-reinforced plastic laminates with various hole shapes. Adv. Compos. Mater 30, 58–75 (2021). https://doi.org/10.1080/09243046.2020.1783077

Bernaud, D., Quevedo, F.P.M.: Analytical solution of deep tunnels in a strain-hardening elasto-plastic rock mass. Lat. Am. J. Solids Struct. 17, e297 (2020). https://doi.org/10.1590/1679-78256023

Wang, W., Yuan, H., Li, X., Shi, P.: Stress concentration and damage factor due to central elliptical hole in functionally graded panels subjected to uniform tensile traction. Materials 12, 422 (2019). https://doi.org/10.3390/ma12030422

Huang, Y.-H., Yang, S.-Q., Tian, W.-L.: Cracking process of a granite specimen that contains multiple pre-existing holes under uniaxial compression. Fatigue Fract. Eng. Mater. Struct. 42, 1341–1356 (2019). https://doi.org/10.1111/ffe.12990

Tuna, M., Trovalusci, P.: Stress distribution around an elliptic hole in a plate with ‘implicit’ and ‘explicit’ non-local models. Compos. Struct. 256, 113003 (2021). https://doi.org/10.1016/j.compstruct.2020.113003

Murru, P.T., Rajagopal, K.R.: Stress concentration due to the presence of a hole within the context of elastic bodies. Mater. Des. Process. Commun. 3, e219 (2021). https://doi.org/10.1002/mdp2.219

Murru, P.T., Rajagopal, K.R.: Stress concentration due to the bi-axial deformation of a plate of a porous elastic body with a hole. Z. Angew. Math. Mech. 101, e202100103 (2021). https://doi.org/10.1002/zamm.202100103

Fulop, T., Szucs, M.: Analytical solutions for rheological processes around bores and tunnels. J. Eng. Math. 136, 1 (2022). https://doi.org/10.1007/s10665-022-10235-6

Jafari Fesharaki, J., Roghani, M.: Mechanical behavior and optimization of functionally graded hollow cylinder with an elliptic hole. Mech. Adv. Comp. Struct. (2020). https://doi.org/10.22075/macs.2020.17213.1200

Yin, C., Lu, A., Zeng, X.: An accurate and efficient computational method for seeking two equi-tangential stress hole shapes. Arch. Appl. Mech. 89, 2321–2334 (2019). https://doi.org/10.1007/s00419-019-01578-1

Cai, H., Lu, A.-Z., Ma, Y.-C.: Shape optimization of two interacting holes with different areas in an infinite plate. Eur. J. Mech. A/Solids 78, 103844 (2019). https://doi.org/10.1016/j.euromechsol.2019.103844

Zeng, X., Lu, A., Wang, S.: Shape optimization of two equal holes in an infinite elastic plate. Mech. Based Des. Struct. Mach. 48, 1–13 (2019). https://doi.org/10.1080/15397734.2019.1620111

Thomason, P.: A view on ductile-fracture modelling. Fatigue Fract. Eng. Mater. Struct. 21, 1105–1122 (1998). https://doi.org/10.1046/j.1460-2695.1998.00077.x

Ma, Y., Lu, A., Cai, H.: Analytical method for determining the elastoplastic interface of a circular hole subjected to biaxial tension-compression loads. Mech. Based Des. Struct. Mach. 50, 3206–3223 (2022). https://doi.org/10.1080/15397734.2020.1801461

McCue, S.W., Hill, J.M.: Free surface problems for static Coulomb–Mohr granular solids. Math. Mech. Solids 10, 651–672 (2005). https://doi.org/10.1177/1081286505036423

Hill, R.: The Mathematical Theory of Plasticity. Clarendon Press, Oxford (1950)

Alexandrov, S.: Geometry of plane strain characteristic fields in pressure-dependent plasticity. Z. Angew. Math. Mech. 95, 1296–1301 (2015). https://doi.org/10.1002/zamm.201400017

Alexandrov, S., Date, P.: A general method of stress analysis for a generalized linear yield criterion under plane strain and plane stress. Contin. Mech. Thermodyn. 31, 841–849 (2019). https://doi.org/10.1007/s00161-018-0743-6

Alexandrov, S.E., Lyamina, E.A.: A new method of calculating the state of stress in granular materials under plane strain conditions. Transp. Syst. Technol. 3, 89–106 (2017). https://doi.org/10.1016/0022-5096(64)90029-8

Spencer, A.J.M.: A theory of the kinematics of ideal soils under plane strain conditions. J. Mech. Phys. Solids 12, 337–351 (1964). https://doi.org/10.1016/0022-5096(64)90029-8

Zhu, S.-P., Ye, W.-L., Correia, J.A.F.O., Jesus, A.M.P., Wang, Q.: Stress gradient effect in metal fatigue: review and solutions. Theor. Appl. Fract. Mech. 121, 103513 (2022). https://doi.org/10.1016/j.tafmec.2022.103513

Masmoudi, M., Kaddouri, W., Kanit, T., Madani, S., Ramtani, S., Imad, A.: Modeling of the effect of the void shape on effective ultimate tensile strength of porous materials: numerical homogenization versus experimental results. Int. J. Mech. Sci. 130, 497–507 (2017). https://doi.org/10.1016/j.ijmecsci.2017.06.011

Owen, D.R.J., Nayak, G.C., Kfouri, A.P., Griffiths, J.R.: Stresses in a partly yielded notched bar—an assessment of three alternative programs. Int. J. Numer. Methods Eng. 6, 63–73 (1973). https://doi.org/10.1002/nme.1620060108

Abali, B.E., Reich, F.A.: Verification of deforming polarized structure computation by using a closed-form solution. Contin. Mech. Thermodyn. 32, 693–708 (2020). https://doi.org/10.1007/s00161-018-0709-8

Wu, S.-X., Mai, Y.-W., Cotterell, B.: Slip-line field solutions of three-point bend specimens with deep notches. Int. J. Mech. Sci. 29, 557–564 (1987). https://doi.org/10.1016/0020-7403(87)90027-0

Jeong, H.-Y., Li, X.-W., Yee, A.F., Pan, J.: Slip lines in front of a round notch tip in a pressure-sensitive material. Mech. Mater. 19, 29–38 (1994). https://doi.org/10.1016/0167-6636(94)90035-3

Acknowledgements

This work was made possible by the NCKU 90 and AAAA-A20-120011690136-2 programs. It was financially supported by the Ministry of Science and Technology of Taiwan (MOST 106-2923-E-194-002-MY3, 108- 2221-E-006-228-MY3 and 108-2119-M-006-010) and Air Force Office of Science Research (AFOSR) under Contract No. FA4869- 06-1-0056 AOARD 064053. Professor Yeau-Ren Jeng would like to acknowledge Medical Device Innovation Center (MDIC) and Intelligent Manufacturing Research Center (iMRC) from The Featured Areas Research Center Program within the framework of the Higher Education Sprout Project by the Ministry of Education (MOE) in Taiwan and AC2T research GmbH (AC2T) in Austria (COMET InTribology, FFG-No.872176).

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Andreas Öchsner.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alexandrov, S., Lyamina, E. & Jeng, YR. A general stress solution in a plastic region near a traction-free boundary of arbitrary shape under plane-strain conditions. Continuum Mech. Thermodyn. 35, 121–139 (2023). https://doi.org/10.1007/s00161-022-01173-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-022-01173-w