Abstract

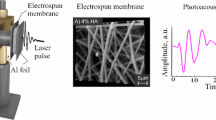

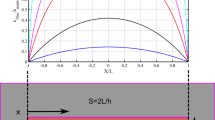

In this paper, a simple phenomenological model describing the macroscopic mechanical response of electrospun nanofibrous structures is proposed. Motivated by the experimental observation, the model development starts from the description of membrane response at fiber scale in order to capture individual fiber response and irreversible inter-fiber interactions using hyperelastic and large strain elasto-plastic frameworks, respectively. The macroscopic response is subsequently obtained by integrating the fiber responses in all possible fiber orientations. The efficiency of the proposed model is assessed using experimental data of PVDF electrospun nanofibrous membranes. It is found that the model is qualitatively in good agreement with uniaxial monotonic and cyclic tensile loading tests. Two other deformation modes, i.e., equibiaxial extension and pure shear (planar extension), are simulated to further evaluate the model responses. Finally, the deformation-induced fiber re-orientation is investigated for different modes of deformations.

Similar content being viewed by others

References

Gopal, R., Kaur, S., Ma, Z., Chan, C., Ramakrishna, S., Matsuura, T.: Electrospun nanofibrous filtration membrane. J. Membr. Sci. 281(1), 581–586 (2006)

Wang, R., Liu, Y., Li, B., Hsiao, B.S., Chu, B.: Electrospun nanofibrous membranes for high flux microfiltration. J. Membr. Sci. 392, 167–174 (2012)

Liao, Y., Wang, R., Tian, M., Qiu, C., Fane, A.G.: Fabrication of polyvinylidene fluoride (PVDF) nanofiber membranes by electro-spinning for direct contact membrane distillation. J. Membr. Sci. 425, 30–39 (2013)

Dehghan, S.F., Golbabaei, F., Maddah, B., Latifi, M., Pezeshk, H., Hasanzadeh, M., Akbar-Khanzadeh, F.: Optimization of electrospinning parameters for polyacrylonitrile-mgo nanofibers applied in air filtration. J. Air Waste Manag. Assoc. 66(9), 912–921 (2016)

Nerurkar, N.L., Elliott, D.M., Mauck, R.L.: Mechanics of oriented electrospun nanofibrous scaffolds for annulus fibrosus tissue engineering. J. Orthopaed. Res. 25(8), 1018–1028 (2007)

Pillay, V., Dott, C., Choonara, Y.E., Tyagi, C., Tomar, L., Kumar, P., du Toit, L.C., Ndesendo, V.M.K.: A review of the effect of processing variables on the fabrication of electrospun nanofibers for drug delivery applications. J. Nanomater. 2013, 22 (2013)

Sill, T.J., von Recum, H.A.: Electrospinning: applications in drug delivery and tissue engineering. Biomaterials 29(13), 1989–2006 (2008)

Jiang, T., Carbone, E.J., Lo, K.W.-H., Laurencin, C.T.: Electrospinning of polymer nanofibers for tissue regeneration. Prog. Polym. Sci. 46, 1–24 (2015)

Yang, G.-Z., Li, J.-J., Yu, D.-G., He, M.-F., Yang, J.-H., Williams, G.R.: Nanosized sustained-release drug depots fabricated using modified tri-axial electrospinning. Acta Biomater. 53, 233–241 (2017)

Zamani, M., Prabhakaran, M.P., Ramakrishna, S.: Advances in drug delivery via electrospun and electrosprayed nanomaterials. Int. J. Nanomed. 8(1), 2997–3017 (2013)

Deitzel, J., Kosik, W., McKnight, S., Tan, N.B., DeSimone, J.M., Crette, S.: Electrospinning of polymer nanofibers with specific surface chemistry. Polymer 43(3), 1025–1029 (2002)

Gao, K., Hu, X., Dai, C., Yi, T.: Crystal structures of electrospun pvdf membranes and its separator application for rechargeable lithium metal cells. Mater. Sci. Eng. B 131(1), 100–105 (2006)

Cozza, E.S., Monticelli, O., Marsano, E., Cebe, P.: On the electrospinning of PVDF: influence of the experimental conditions on the nanofiber properties. Polym. Int. 62(1), 41–48 (2013)

Khanlou, H.M., Sadollah, A., Ang, B.C., Kim, J.H., Talebian, S., Ghadimi, A.: Prediction and optimization of electrospinning parameters for polymethyl methacrylate nanofiber fabrication using response surface methodology and artificial neural networks. Neural Comput. Appl. 25(3–4), 767–777 (2014)

Cai, X., Zhu, P., Lu, X., Liu, Y., Lei, T., Sun, D.: Electrospinning of very long and highly aligned fibers. J. Mater. Sci. 52(24), 14004–14010 (2017)

Lee, J.J.L., Ang, B.C., Andriyana, A., Shariful, M.I., Amalina, M.: Fabrication of PMMA/zeolite nanofibrous membrane through electrospinning and its adsorption behavior. J. Appl. Polym. Sci. 134(6), 1–13 (2017)

Jearanaisilawong, P.: A continuum model for needlepunched nonwoven fabrics. Ph.D. Thesis, Massachusetts Institute of Technology (2008)

King, M., Jearanaisilawong, P., Socrate, S.: A continuum constitutive model for the mechanical behavior of woven fabrics. Int. J. Solids Struct. 42(13), 3867–3896 (2005)

Nadler, B., Papadopoulos, P., Steigmann, D.J.: Multiscale constitutive modeling and numerical simulation of fabric material. Int. J. Solids Struct. 43(2), 206–221 (2006)

Raina, A., Linder, C.: A homogenization approach for nonwoven materials based on fiber undulations and reorientation. J. Mech. Phys. Solids 65, 12–34 (2014)

Ridruejo, A., González, C., LLorca, J.: A constitutive model for the in-plane mechanical behavior of nonwoven fabrics. Int. J. Solids Struct. 49(17), 2215–2229 (2012)

Shim, V., Tan, V., Tay, T.: Modelling deformation and damage characteristics of woven fabric under small projectile impact. Int. J. Impact Eng. 16(4), 585–605 (1995)

Wei, X., Xia, Z., Wong, S.-C., Baji, A.: Modelling of mechanical properties of electrospun nanofibre network. Int. J. Exp. Comput. Biomech. 1(1), 45–57 (2009)

Dupaix, R.B., Hosmer, J.E.D.: Mechanical characterization and finite strain constitutive modeling of electrospun polycaprolactone under cyclic loading. Int. J. Struct. Changes Sol. 2(1), 9–17 (2010)

Silberstein, M.N., Pai, C.-L., Rutledge, G.C., Boyce, M.C.: Elastic-plastic behavior of non-woven fibrous mats. J. Mech. Phys. Solids 60(2), 295–318 (2012)

Arruda, E.M., Boyce, M.C.: A three-dimensional constitutive model for the large stretch behavior of rubber elastic materials. J. Mech. Phys. Solids 41(2), 389–412 (1993)

Planas, J., Guinea, G., Elices, M.: Constitutive model for fiber-reinforced materials with deformable matrices. Phys. Rev. E 76(4), 041903 (2007)

Doshi, J., Reneker, D.H.: Electrospinning process and applications of electrospun fibers. J. Electrostat. 35(2–3), 151–160 (1995)

Greiner, A., Wendorff, J.H.: Electrospinning: a fascinating method for the preparation of ultrathin fibers. Angew. Chem. Int. Ed. 46(30), 5670–5703 (2007)

Baji, A., Mai, Y.-W., Wong, S.-C., Abtahi, M., Chen, P.: Electrospinning of polymer nanofibers: effects on oriented morphology, structures and tensile properties. Compos. Sci. Technol. 70(5), 703–718 (2010)

Huang, Z.-M., Zhang, Y., Ramakrishna, S., Lim, C.: Electrospinning and mechanical characterization of gelatin nanofibers. Polymer 45(15), 5361–5368 (2004)

Molnar, K., Vas, L.M., Czigany, T.: Determination of tensile strength of electrospun single nanofibers through modeling tensile behavior of the nanofibrous mat. Compos. Part B Eng. 43(1), 15–21 (2012)

Wong, D., Andriyana, A., Ang, B.C., Verron, E.: Surface morphology and mechanical response of randomly oriented electrospun nanofibrous membrane. Polym. Test. 53, 108–115 (2016)

Verron, E.: Questioning numerical integration methods for microsphere (and microplane) constitutive equations. Mech. Mater. 89, 216–228 (2015)

Simo, J.C., Hughes, T.J.: Computational Inelasticity, vol. 7. Springer, New York (2006)

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Andreas Öchsner.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wong, D., Verron, E., Andriyana, A. et al. Constitutive modeling of randomly oriented electrospun nanofibrous membranes. Continuum Mech. Thermodyn. 31, 317–329 (2019). https://doi.org/10.1007/s00161-018-0687-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-018-0687-x