Abstract

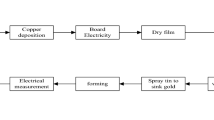

This paper addresses the problem of automatic optical phase identification of micro-drill bits for micro-drilling tool inspection in printed circuit board production. To overcome the limitations of conventional active shape model (ASM) on shape modeling of micro-drill bits, six key landmarks are defined for the initialization and optimization of ASM, and a novel method based on projection profiles is also proposed for these key landmarks detection. In addition, to involve the local shape feature, a bag of shape segment (BoSS) model is developed. Based on the improved ASM and BoSS, a new shape representation of micro-drill bits is proposed for phase identification. Experimental results show that the proposed method outperforms the conventional ASM and can improve the phase identification accuracy of micro-drill bits.

Similar content being viewed by others

References

Duan, G.F., Chen, Y.W., Sukegawa, T.: Automatic optical flank wear measurement of microdrills using level set for cutting plane segmentation. Mach. Vis. Appl. 21(5), 667–676 (2010)

Su, J.C., Huang, C.K., Tang, Y.S.: An automatic flank wear measurement of microdrills using machine vision. J. Mater. Process. Technol. 180(1–3), 328–335 (2006)

Tien, F.-C., Yeh, C.-H., Hsieh, K.-H.: Automated visual inspection for microdrills in printed circuit board production. Int. J. Prod. Res. 42(12), 2477–2495 (2004)

Moganti, M., Ercal, F., Dagli, C.H., Tsunekawa, S.: Automatic PCB inspection algorithms: a survey. Comput. Vis. Image Underst. 63(2), 287–313 (1996)

Bayro-Corrochano, E.: Review of automated visual inspection 1983 to 1993 part I: conventional approaches. SPIE Intell. Robots Comput. Vis. XII 2055, 128–158 (1993)

Zhang, W.J., Li, D., Ye, F., Sun, H.: Automatic optical defect inspection and dimension measurement of drill bit. IEEE International Conference on Mechatronics and Automation, pp. 95–100 (2006)

Huang, C.K., Liao, C.W., Huang, A.P., Tarng, Y.S.: An automatic optical inspection of drill point defects for micro-drilling. Int. J. Adv. Manuf. Technol. 37, 1133–1145 (2007)

Duan, G.F., Chen, Y.W., Sukekawa, T.: Automatic optical phase identification of microdrill bits using active shape models. IEEE international Instrumentation and Measurement Technology Conference, pp. 279–283 (2009)

Duan, G.F., Chen, Y.W.: Improved active shape model for automatic optical phase identification of microdrill bits in printed circuit Board production. IEEE International Conference on Image Processing, pp. 425–428 (2009)

Abe, S.: Support Vector Machines for Pattern Classification. Springer, London (2005)

Kim, K.I., Jung, K., Park, S.H., Kim, H.J.: Support vector machines for texture classification. IEEE Trans. Pattern Anal. Mach. Intell. 24(11), 1542–1550 (2002)

Cootes, T.F., Taylor, C.J., Cooper, D.H., Graham, J.: Active shape models-their training and application. Comput. Vis. Image Underst. 61(1), 38–59 (1995)

Hamarneh, G.: Active shape models, modeling shape variations and gray level information and an application to image search and classification. Technical Report R005/1998 (S2-IAG-98-1). Chalmers University of Technology, Goteborg (1998)

Mohammad, H.M., Mohamed, A.-M.: Facial features extraction in color images using enhanced active shape model. Seventh IEEE International Conference on Automatic Face and Gesture Recognition, pp. 144–148 (2006)

Wimmer, M., Stulp, F., Pietzsch, S., Radig, B.: Learning local objective functions for robust face model fitting. IEEE Trans. Pattern Anal. Mach. Intell. 30(8), 1357–1370 (2008)

Csurka, G., Bray, C., Dance, C., Fan, L.: Visual categorization with bags of key points, pp. 1–24. Workshop on Statistical Learning in Computer Vision, ECCV (2004)

Fulkerson, B., Vedaldi, A., Soatto, S.: Localizing objects with smart dictionaries. European Conference on Computer Vision, pp. 179–192 (2008)

Moosmann, F., Nowak, E., Jurie, F.: Randomized clustering forests for image classification. IEEE Trans. Pattern Anal. Mach. Intell 30(9), 1632–1646 (2008)

Zhang, H., Yang, J., Tao, W., Zhao, H.: Vision method of inspecting missing fastening components in high-speed railway. Appl. Opt. 50(20), 3658–3665 (2011)

Ma, J., Ahalt, S.: OSU SVM Classifier Matlab Toolbox (ver.3.00). http://eewww.eng.ohio-state.edu/~maj/osu_svm (2003)

Acknowledgments

This work was supported in part by Science Fund for Creative Research Groups of National Natural Science Foundation of China (51221004), National Basic Research 973 Program of China (2011CB706503), National Natural Science Foundation of China (51075357), Grant-in-Aid for Scientific Research from the Japanese MEXT (2430076) and the R-GIRO research fund from Ritsumeikan University. The authors would like to thank the companies of Remixpoint and NC Industry.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Duan, G., Wang, H., Liu, Z. et al. Automatic optical phase identification of micro-drill bits based on improved ASM and bag of shape segment in PCB production. Machine Vision and Applications 25, 1411–1422 (2014). https://doi.org/10.1007/s00138-014-0627-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00138-014-0627-0