Abstract

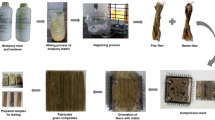

In the present work, medium density fiberboard (MDF) panels were produced using multiwalled carbon nanotubes (MWCNT) reinforced urea formaldehyde resin. Response surface methodology was employed to optimize the relationship between the three variables, viz. pressing time, percentage of UF resin and percentage of MWCNT, used in the fabrication of MDF, and the influence of variables on the internal bonding (IB) and modulus of rupture (MOR) was studied. The optimum conditions based on the IB strength were determined as 8.18 % of UF resin, pressing time of 232 s, and MWCNT of 3.5 %. Similarly, the optimized conditions for MOR are also reported in this paper.

Similar content being viewed by others

References

Arepalli S, Nikolaev P, Gorelik O, Hadjiev V, Holmes W, Files B, Yowell L (2004) Protocol for the characterization of single-wall carbon nanotube material quality. Carbon 42(8–9):1783

Atieh MA, Bakather OY, Al-Tawbini B, Bukhari AA, Abuilaiwi FA, Fettouhi MB (2010) Effect of carboxylic functional group functionalized on carbon nanotubes surface on the removal of lead from water. Bioinorg Chem Appl. doi:10.1155/2010/603978

Box GP, Behnken DW (1960) Some new three level design for the study of quantitative variables. Technometrics 2:456–475

Cai X, Riedl B, Wan H, Zhang SY, Wang XM (2010) A study on the curing and viscoelastic characteristics of melamine-urea-formaldehyde adhesive in the presence of aluminum silicate nanoclays. Compos Part A 41:604–611

Candan Z, Akbulut T (2014) Nano-engineered plywood panels: performance properties. Compos B Eng 64:155–161

Candan Z, Akbulut T (2015) Physical and mechanical properties of nanoreinforced particleboard composites. Maderas. Cienc y tecnol 17(2):319–334

Candan Z, Gardner DJ, Shaler SM (2016) Dynamic mechanical thermal analysis (DMTA) of cellulose nanofibril/nanoclay/pMDI nanocomposites. Compos B Eng 90:126–132

Chen N, Lin Q, Zeng Q, Rao J (2013) Optimization of preparation conditions of soy flour adhesive for plywood by response surface methodology. Ind Crops Prod 51:267–273

Dudkin BN, Krivoshapkin VP, Krivoshapkina EF (2006) Effect of aluminum oxide nanoparticles on the properties of urea-formaldehyde resin. Russ J Appl Chem 79(9):1522–1525

Ebewele RO (1995) Differential scanning calorimetry and dynamic mechanical analysis of amine-modified urea–formaldehyde adhesives. J Appl Polym Sci 58(10):1689–1700

EN 310 (1993) Wood based panels, determination of modulus of elasticity in bending and bending strength. European Committee for Standardization, Brussels

EN 319 (1993) Particleboards and fibreboards. Determination of tensile strength perpendicular to the plane of the board. European Committee for Standardization, Brussels

Fang Q, Cui HW, Du GB (2014) Montmorillonite reinforced phenol formaldehyde resin: preparation, characterization, and application in wood bonding. Int J Adhes Adhes 49:33–37

Hasany SF, Abdurahman NH, Sunarti AR, Kumar A (2013) Non-covalent assembly of maghemite-multiwalled carbon nanotubes for efficient lead removal from aqueous solution. Aust J Chem 66(11):1440–1446

Hauptmann M, Lubin JH, Stewart PA, Hayes RB, Blair A (2004) Mortality from solid cancers among workers in formaldehyde industries. Am J Epidemiol 159(12):1117–1130

Iijima S (1991) Helical microtubules of graphitic carbon. Nature 354(6348):56–58

Irle M, Barbu MC (2010) Wood based panels: an introduction for specialists. Brunel University Press, London

Islam MA, Alam MR, Hannan MO (2012) Multiresponse optimization based on statistical response surface methodology and desirability function for the production of particleboard. Compos B Eng 43(3):861–868

Islam MA, Razzak MA, Ghosh B (2014) Optimization of thermally-compressed wood of Trewia nudiflora species using statistical Box-Behnken design and desirability function. J Indian Acad Wood Sci 11(1):5–14

Jovanović V, Samaržija-Jovanović S, Petković B, Dekić V, Marković G, Marinović-Cincović M (2015) Effect of γ-irradiation on the hydrolytic and thermal stability of micro-and nano-TiO2 based urea–formaldehyde composites. RSC Adv 5(73):59715–59722

Kamoun C, Pizzi A, Zanetti M (2003) Upgrading melamine–urea–formaldehyde poly-condensation resins with buffering additives. I. The effect of hexamine sulfate and its limits. J Appl Polym Sci 90(1):203–214

Kelly MW (1977) Critical Literature Review of Relationships Between Processing Parameters and Physical Properties of Particleboard (Rep. No. FPL-10, May 1977). Madison, Wisconsin: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory

Kim S, Kim HJ, Kim HE, Lee YK (2006) Thermal analysis study of viscoelastic properties and activation energy of melamine-modified urea-formaldehyde resins. J Adhes Sci Technol 20(8):803–816

Kumar A, Gupta A, Sharma KV, Nasir M (2013a) Use of aluminum oxide nanoparticles in wood composites to enhance the heat transfer during hot-pressing. Eur J Wood Prod 71(2):193–198

Kumar A, Gupta A, Sharma KV, Gazali SB (2013b) Influence of aluminum oxide nanoparticles on the physical and mechanical properties of wood composites. BioResources 8(4):6231–6241

Kumar A, Gupta A, Sharma KV, Nasir M, Khan TA (2013c) Influence of activated charcoal as filler on the properties of wood composites. Int J Adhes Adhes 46:34–39

Kumar A, Gupta A, Sharma KV (2015) Thermal and mechanical properties of urea-formaldehyde (UF) resin combined with multiwalled carbon nanotubes (MWCNT) as nanofiller and fiberboards prepared by UF-MWCNT. Holzforschung 69(2):199–205

Kumar A, Ryparová P, Škapin AS, Humar M, Pavlič M, Tywoniak J, Hajek P, Žigon J, Petrič M (2016a) Influence of surface modification of wood with octadecyltrichlorosilane on its dimensional stability and resistance against Coniophora puteana and molds. Cellulose 23(5):3249–3263

Kumar A, Staněk K, Ryparová P, Hajek P, Tywoniak J (2016b) Hydrophobic treatment of wood fibrous thermal insulator by octadecyltrichlorosilane and its influence on hygric properties and resistance against moulds. Compos B Eng 106:285–293

Lei LH, Du G, Pizzi A, Celzard A (2008) Influence of nanoclay on urea-formaldehyde adhesives for wood adhesives and its model. J Appl Polym Sci 109:2442–2451

Lin Q, Yang G, Liu J, Rao J (2006) Property of nano-SiO2/urea formaldehyde resin. Front For China 1(2):230–237

Myers RH, Montgomery DC (1995) Response surface methodology: process and product optimization using designed experiments. Wiley, New York

Park BD, Jeong HW (2011) Hydrolytic stability and crystallinity of cured urea–formaldehyde resin adhesives with different formaldehyde/urea mole ratios. Int J Adhes Adhes 31(6):524–529

Rinzler AG, Liu J, Dai H, Nikolaev P, Huffman CB, Rodriguez-Macias FJ, Boul PJ, Lu AH, Heymann D, Colbert DT, Lee RS (1998) Large-scale purification of single-wall carbon nanotubes: process, product, and characterization. Appl Phys A Mater Sci Process 67(1):29–37

Samaržija-Jovanović S, Jovanović V, Konstantinović S, Marković G, Marinović-Cincović M (2010) Thermal behavior of modified urea–formaldehyde resins. J Therm Anal Calorim 104(3):1159–1166

Singh BP, Singh D, Mathur RB, Dhami TL (2008) Influence of surface modified MWCNTs on the mechanical, electrical and thermal properties of polyimide nanocomposites. Nanoscale Res Lett 3(11):444–453

Sinnott SB, Andrews R (2001) Carbon nanotubes: synthesis, properties, and applications. Crit Rev Solid State Mater Sci 26(3):145–249

Teruel ML, Gontier E, Bienaime C, Saucedo JE, Barbotin JN (1997) Response surface analysis of chlortetracycline and tetracycline production with k-carrageenan immobilized Streptomyces aureofaciens. Enzym Microbiol Technol 21:314–320

Tohmura S, Hse CY, Higuchi M (2000) Formaldehyde emission and high temperature stability of cured urea–formaldehyde resins. J Wood Sci 46:303–309

Tomita B, Hse CY (1995) Analysis on co-condensation of melamine and urea through carbon 13 enriched formaldehyde with carbon 13 Nuclear Magnetic Resonance Spectroscopy. Mokuzai Gakkaishi 41(5):490–497

Weinstabl A, Binder WH, Gruber H, Kantner W (2001) Melamine salts as hardeners for urea formaldehyde resins. J Appl Polym Sci 81(7):1654–1661

Xian D (2012) Effects of nanoclay filler on wood adhesives and particle board properties. M.S Thesis, The University of British Columbia, Canada

Yu YS, Ni CY, Yu T, Wan H (2015) Optimization of mechanical properties of bamboo plywood. Wood Fiber Sci 47(1):1–11

Zanetti M, Pizzi A (2003) Low addition of melamine salts for improved melamineurea-formaldehyde adhesive water resistance. J Appl Polym Sci 88(2):287–292

Zhang H, She Y, Song S, Lang Q, Pu J (2011) Modified nanocrystalline cellulose from two kinds of modifiers used for improving formaldehyde emission and bonding strength of urea-formaldehyde resin adhesive. BioResources 6(4):4430–4438

Zhang H, She Y, Song S, Lang Q, Pu J (2013) Particulate reinforcement and formaldehyde adsorption of modified nanocrystalline cellulose in urea-formaldehyde resin adhesive. J Adhes Sci Technol 27(9):1023–1031

Acknowledgments

We acknowledge the support of Ministry of Education, Youth and Sports, Czech Republic, within National Sustainability Programme I (NPU I), Project No. LO1605––University Centre for Energy Efficient Buildings––Sustainability Phase. The authors also acknowledge the Universiti Malaysia Pahang for a research Grant (GRS 10308).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, A., Sharma, K.V., Gupta, A. et al. Optimization of processing parameters of medium density fiberboard using response surface methodology for multiwalled carbon nanotubes as a nanofiller. Eur. J. Wood Prod. 75, 203–213 (2017). https://doi.org/10.1007/s00107-016-1106-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-016-1106-2