Abstract

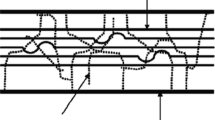

Microwave-assisted liquefaction of bamboo in glycerol, polyethylene glycerol (PEG), methanol, ethanol, and water were comparatively investigated by evaluating the temperature-dependence for conversion and liquefied residue characteristics. The conversion for the liquefaction in methanol, ethanol, and water increased with an increase in reaction temperature, while that for liquefaction in glycerol and PEG was converse. The results of Fourier transform-infrared spectra for the liquefied residues revealed that cellulose was the main resistance to bamboo liquefaction in methanol, ethanol, and water. Glycerol could be selected as a commendable liquefacient for the solvolysis of bamboo components at low temperature using microwave energy. Moreover, liquefaction behaviors in glycerol and methanol under different temperatures were also distinguished by scanning electron microscopy images.

Similar content being viewed by others

References

Antal MJ, Leesomboon T, Mok WS, Richards GN (1991) Mechanism of formation of 2-furaldehyde from xylose. Carbohyd Res 217:71–85

Cinta P, Tagliapietra S, Gaudino EC, Palmisano G, Cravotto G (2014) Glycerol: a solvent and a building block of choice for microwave and ultrasound irradiation procedures. Green Chem 16:1056–1065

Gao L, Liu Y, Lei H, Peng H, Ruan R (2010) Preparation of semirigid polyurethane foam with liquefied bamboo residues. J Appl Polym Sci 116(3):1694–1699

Kabyemela BM, Adschiri T, Malaluan RM, Arai K, Ohzeki H (1997) Rapid and selective conversion of glucose to erythrose in supercritical water. Ind Eng Chem Res 36(12):5063–5067

Li Z, Han L, Xiao W (2013) Influence of microwave heating on the liquefaction kinetics of corn stover in ethylene glycol. Bioresources 8(4):3453–3460

Liu ZG, Zhang FS (2008) Effect of various solvents on the liquefaction of biomass to produce fuels and chemical feedstocks. Energy Convers Manage 49:3498–3504

Liu Y, Gao L, Luo A, Rong R, Liu C (2008) Polyurethane foams made from combined liquefaction mixtures of bamboo residues and starch. Acta Polym Sin 6:546–549

Pan H, Zheng ZF, Hse CY (2012) Microwave-assisted liquefaction of wood with polyhydric alcohols and its application in preparation of polyurethane (PU) foams. Eur J Wood Prod 70(4):461–470

Popescu CM, Singurel G, Popescu MC, Cornelia Vasile D, Argyropoulos DS, Willfor S (2009) Vibrational spectroscopy and X-ray diffraction methods to establish the differences between hardwood and softwood. Carbohyd Polym 77:851–857

Qi JQ, Xie JL, Hse CY, Shupe TF (2013) Analysis of Phyllostachys pubescens bamboo residues for liquefaction: chemical components, infrared spectroscopy, and thermogravimetry. Bioresource 8(4):5644–5654

Rizk HA, Elanwar IM (1968) Dipole moments of glycerol, isopropyl alcohol, and isobutyl alcohol. Can J Chem 46:507–513

Toor SS, Reddy H, Deng S, Hoffmann J, Spangsmark D, Madsen LB, Holm-Nielsen JB, Rosendahi LA (2013) Hydrothermal liquefaction of Spirulina and Nannochloropsis salina under subcritical and supercritical water conditions. Bioresour Technol 131:413–419

Xiao W, Niu W, Yi F, Liu X, Han L (2013) Influence of crop residue types on microwave-assisted liquefaction performance and products. Energy Fuel 27(6):3204–3208

Xu JM, Jiang JX, Hse CY, Shupe TF (2013) Effect of methanol on the liquefaction reaction of biomass in hot compressed water under microwave energy. Energy Fuel 27:4791–4795

Yip J, Chen M, Szeto YS, Yan S (2009) Comparative study of liquefaction process and liquefied products from bamboo using different organic solvents. Bioresour Technol 100(24):6674–6678

Zhang MY (2003) Study on auto-catalyzed ethanol–water pulping and mechanism of non-wood fiber. Ph.D. dissertation, Tianjin University of Science and Technology, Tianjin, China

Zhang J, Du M, Hu L (2013) Microwave liquefaction for bamboo powder polyhydric alcohols and preparation of polyether glycol. Adv Mater Res 726–731:151–155

Zhuang Y, Guo J, Chen L, Li D, Liu J, Ye N (2012) Microwave-assisted direct liquefaction of Ulva prolifera for bio-oil production by acid catalysis. Bioresour Technol 116:133–139

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xie, J., Hse, CY., Shupe, T.F. et al. Influence of solvent type on microwave-assisted liquefaction of bamboo. Eur. J. Wood Prod. 74, 249–254 (2016). https://doi.org/10.1007/s00107-016-1009-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-016-1009-2