Abstract

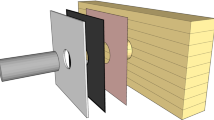

This paper presents a methodology to characterize the secant shearing stiffness of welding-through wood dowels used in multi-layer spruce beams. Welding-through wood dowel’s stiffness behaviour as well as isostatic multi-layer beams’ behaviour were investigated experimentally. These elements are made by a specifically designed machine to guarantee repeatability. A model of finite elements was developed to reproduce the bending behaviour of the beams tested from non-linear connection behaviour. This model is then used to study the influence of parameters such as: layer number, spacing of dowels, load type (concentrated or distributed), strength class and beam span. After a sensibility analysis, a parameterized regression model allows to obtain k ser and k u fastener secant stiffness in compliance with EN 1995-1 standard to design multi-layer beams in an elastic analytical model way. This model is based on the work by Kreuzinger (1999).

Similar content being viewed by others

References

Bocquet J-F, Pizzi A, Despres A, Mansouri HR, Resch L, Michel D, Letort F (2007a) Wood joints and laminated wood beams assembled by mechanically-welded wood dowels. J Adhes Sci Technol 21:301–317

Bocquet J-F, Pizzi A, Resch L (2007b) Full-scale industrial wood floor assembly and structures by welded-through dowels. Eur J Wood Prod 65:149–155

Castro JL, Mantas CJ, Benitez JM (2000) Neural networks with a continuous squashing function in the output are universal approximators. Neural Netw 13:561–563

Ceccotti A (1995) Timber-concrete composite structures. In: Blass HJ, Aune P, Choo BS, Gölacher R, Griffiths DR, Hilson BO et al (eds) Timber engineering, step, vol 2. Centrum Hout, The Netherlands, p E13/1-12

Fragiacomo M, Lukaszewska E (2011) Development of prefabricated timber concrete composite floor systems. Proc Inst Civil Eng Struct Build 164:13

Girard A, Roy N (2003) Dynamique des structures industrielles (In French) (Structural Dynamics in Industry). Hermes Science Publications, Paris

Girhammar UA, Pan DH (2007) Exact static analysis of partially composite beams and beam-columns. Int J Mech Sci 49:239–255

Heimeshoff B (1987) Zur Berechnung von Biegeträgern aus nachgiebig miteinander verbundenen Querschnittsteilen im Ingenieurholzbau. Holz Roh Werkst 45:237–241

Hornik K, Stinchcombe M, White H (1989) Multilayer feedforward networks are universal approximators. Neural Netw 2:359–366

Ilonen J, Kamarainen J-K, Lampinen J (2003) Differential evolution training algorithm for feed-forward neural networks. Neural Process Lett 17:93–105

Kanazawa F, Pizzi A, Properzi M, Delmotte L, Pichelin F (2005) Parameters influencing wood-dowel welding by high-speed rotation, J Adhes Sci Technol 19(12):1025–1038

Kreuzinger H (1999) Flachentragwerke: Platten, Scheiben und Schalen; Berechnungsmethoden und Beispiele, Informationsdienst Holz: Brücken aus Holz:43-60

Le Cun Y, Touresky D, Hinton G, Sejnowski T (1988) A theoretical framework for back-propagation. In: The Connectionist Models Summer School, 1 pp 21–28

Leban JM, Mansouri HR, Omrani P, Pizzi A (2008) Dependence of dowel welding on rotation rate. Holz Roh Werkst 66:241–242

Lukaszewska E (2009) Development of prefabricated timber-concrete composite floors. Doctoral thesis, Luleå tekniska universitet

O’Loinsigh C, Oudjene M, Shotton E, Pizzi A, Fanning P (2012) Mechanical behaviour and 3D stress analysis of multi-layered wooden beams made with welded-through wood dowels. Compos Struct 94:313–321

Pirazzi C (2005) Zur Berechnung von Holzschalen in Brettrippenbauweise mit elastischem Verbundquerschnitt. Doctoral thesis, ENAC

Resch L (2009) Development of locally laminated wood construction elements using welded-through dowels (In French), Doctoral thesis, ENSTIB

Resch L, Despres A, Pizzi A, Bocquet J-F, Leban J-M (2006) Welding-through doweling of wood panels. Eur J Wood Prod 64:423–425

Scholz A (2004) Ein Beitrag zur Berechnung von Flächentragwerken aus Holz. Technische Universität München, Thesis

Shapiro SS, Wilk MB (1965) An analysis of variance test for normality (complete samples). Biometrika 52:591–611

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Girardon, S., Barthram, C., Resch, L. et al. Determination of shearing stiffness parameters to design multi-layer spruce beams using welding-through wood dowels. Eur. J. Wood Prod. 72, 721–733 (2014). https://doi.org/10.1007/s00107-014-0834-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-014-0834-4